Method of pre-treatment of desizing, scouring and bleaching in one-bath process for cotton fabric by ultrasonic pre-treatment

A cotton fabric pretreatment technology, applied in ultrasonic/sonic fiber treatment, bleached products, plant fibers, etc., can solve the problems of long process flow, serious sewage discharge, excessive water consumption, etc., achieve small damage, improve solubility, and save working hours Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] Fabric: Cotton Poplin (40s x 40s, 118 x 89)

[0007] Conventional descouring and bleaching process: ultrasonic pretreatment time is 5min; NaOH 20g / L; 30% hydrogen peroxide 20g / L; oxygen bleaching stabilizer Na 2 SiO 3 7g / L; penetrating agent JFC4g / L; bath ratio 1:30 descouring and bleaching one bath time is 60min, water bath temperature is 85°C.

[0008] Ultrasonic pretreatment cotton fabric descouring and bleaching one-bath process: the first step, ultrasonic pretreatment: ultrasonic frequency 40kHz; ultrasonic power 100w; processing temperature 60 ℃; ultrasonic pretreatment time 5min; One bath of boiling and bleaching: NaOH 20g / L; 30% hydrogen peroxide 20g / L; oxygen bleaching stabilizer Na 2 SiO 3 7g / L; penetrant JFC 4g / L; liquor ratio 1:30, water bath temperature 85°C, act for 30min.

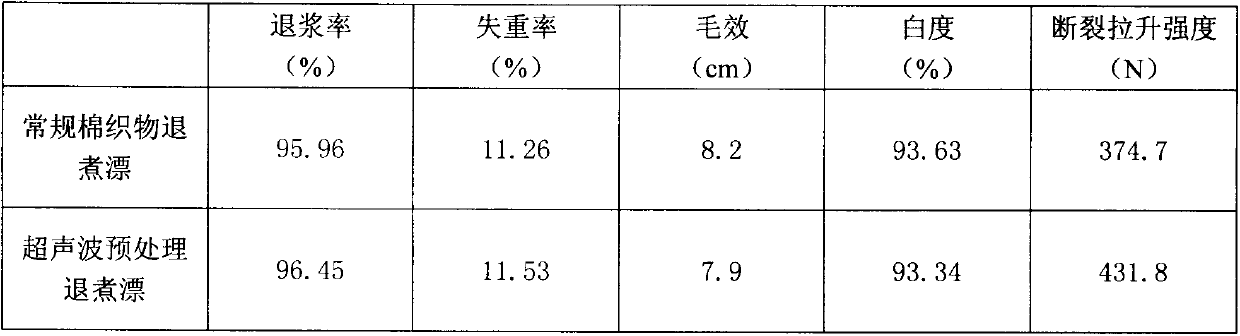

[0009] result:

[0010]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com