Front-arrangement type ice breaking device

A front-mounted, tool bar technology, applied in cleaning methods, snow surface cleaning, construction, etc., can solve the problems of low utilization rate, corrosion, high price, etc., and achieve the effect of high operating efficiency, flexible operation, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

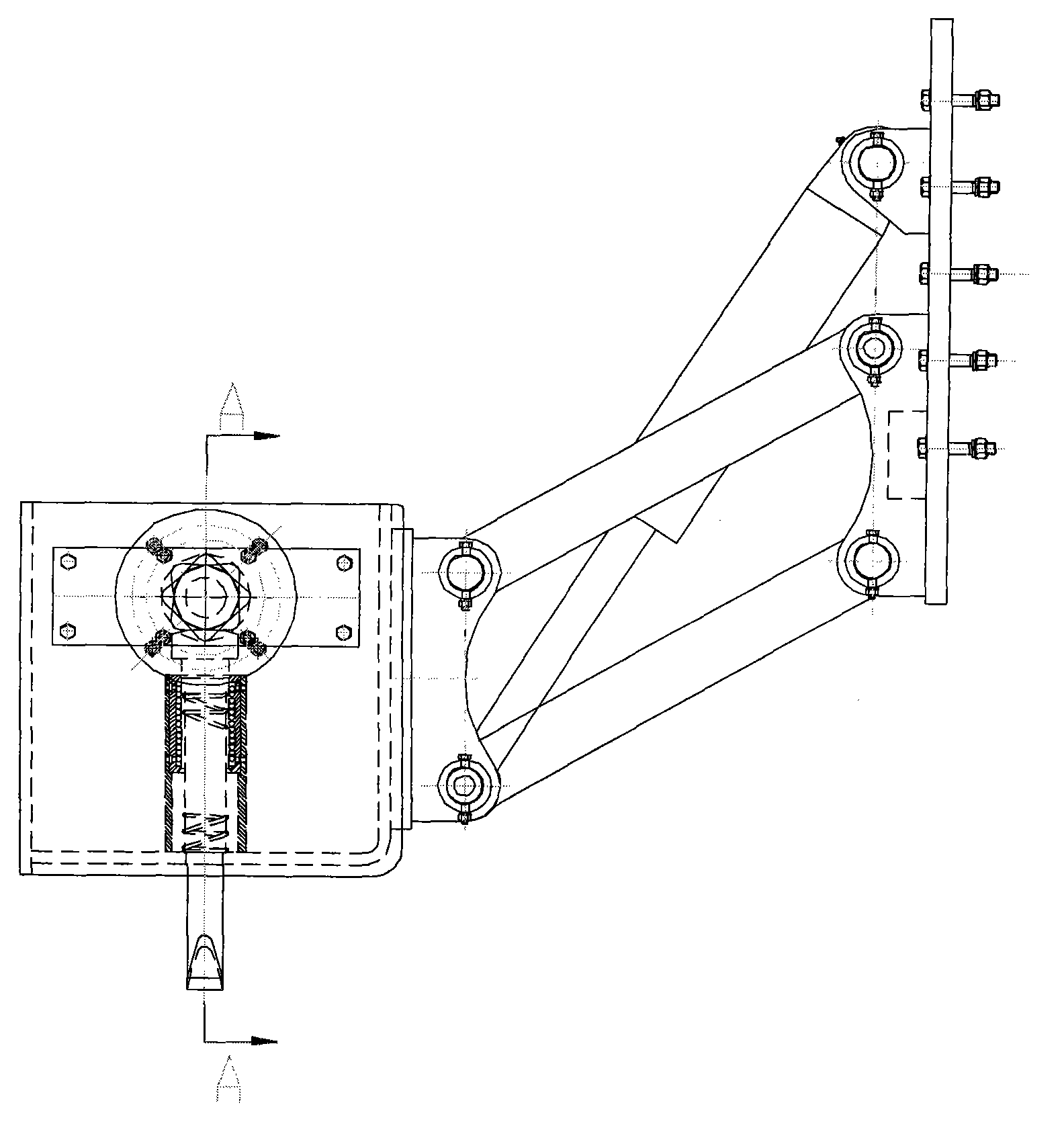

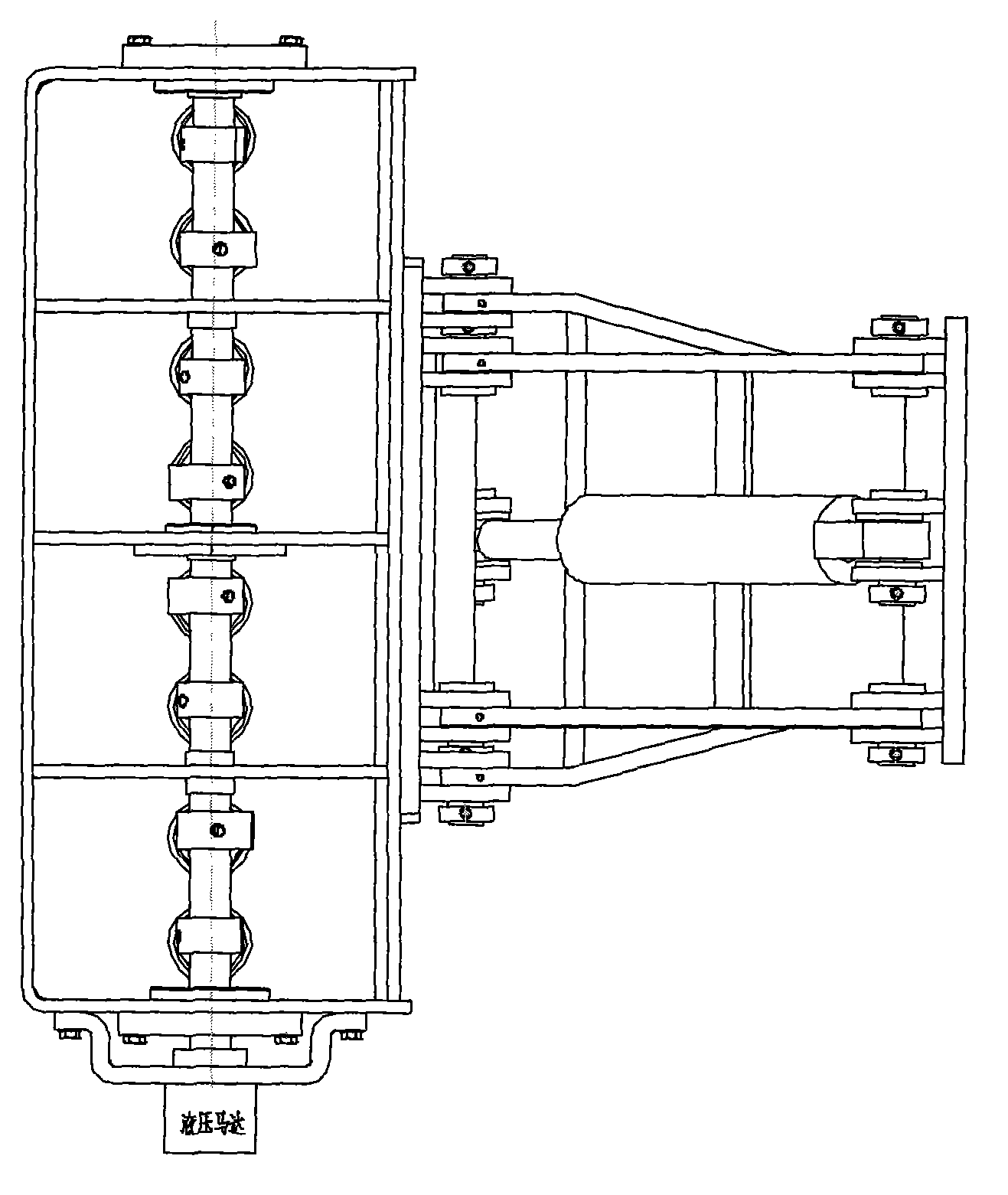

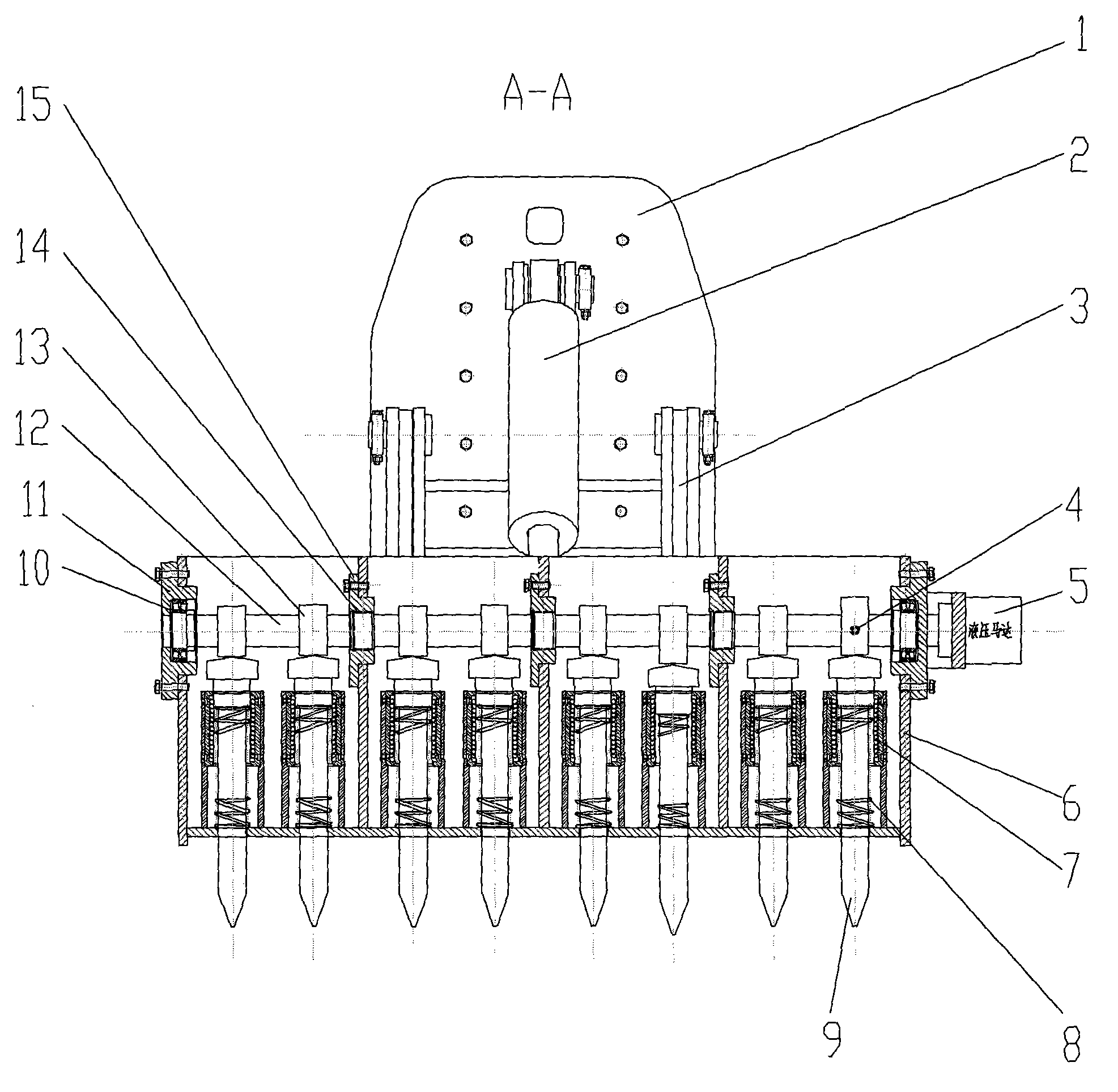

[0018] The support (1) is installed on the front end of the machine through bolts; the support (1) and the tool holder (6) are connected together by the connecting rod (3); the oil cylinder (2) is connected with the support (1) and the tool holder ( 6) Hinged; knife rod (9), linear motion ball bearing (7), compression spring (8) are contained in the knife rod holder (6); cam (13) is installed on camshaft (12) by elastic cylindrical pin (4) ); there are five supporting points on the tool holder (6), the self-aligning roller bearings (10) are fixed on both sides with the end cover I (11), and the split bearing bush (14) is fixed with the end cover II (15) in the middle. ) is fixed; the hydraulic motor (5) is fixed on the tool holder (6) after being connected with the camshaft (12), and through the above installation, this embodiment is completed. During operation, the oil cylinder (2) can be extended and extended according to the required ice-breaking depth to change the height ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com