Method for manufacturing navigation mark concrete bearing platform

A production method and concrete technology, which can be applied to buoys, ships, special-purpose ships, etc., can solve the problems of human and financial waste, reduce construction efficiency, and inconvenient construction, and achieve the goal of reducing overall cost, improving construction efficiency, and protecting the ecological environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

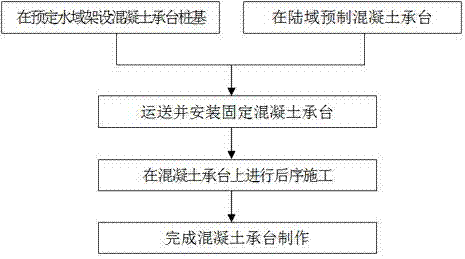

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and the construction of reinforced concrete navigation mark foundation on the promenade connection line of Chaohu Waters, Anhui Province's skirmishing port area as an embodiment.

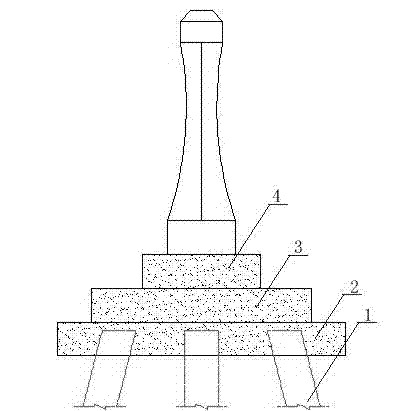

[0030] In this embodiment, the foundation of the navigation mark is composed of three layers of reinforced concrete caps and pile foundations, such as figure 2 shown.

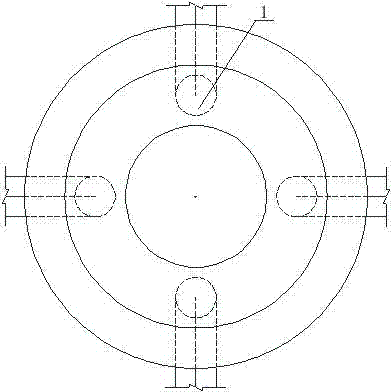

[0031] Navigation mark pile foundation setting: Set up the navigation mark pile foundation in the preset waters of the navigation mark. The pile foundation is composed of 4 PHC pipe piles 1 with a length of 25M and a diameter of 100CM. The top of the pipe pile 1 is 5M away from the water surface. The distance between the center points of 1 circle is 400CM, the slope of pipe pile 1 is 4:1, and the top surface of pipe pile 1 is on the same level, such as image 3 shown.

[0032] Production, transportation and installation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com