BDO device hydrogen compressor high-pressure oil injection structure

A high-pressure oil injection and compressor technology, which is applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve problems such as unfavorable long-term stable operation of equipment, poor reliability of NPT conical unions, hidden dangers to production safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following will be described in detail in conjunction with the embodiments.

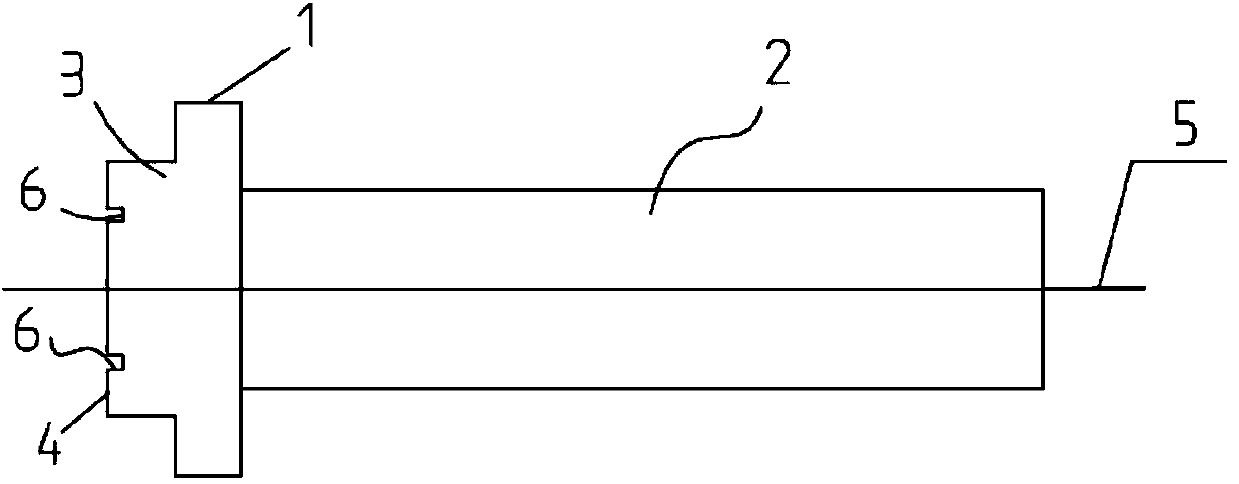

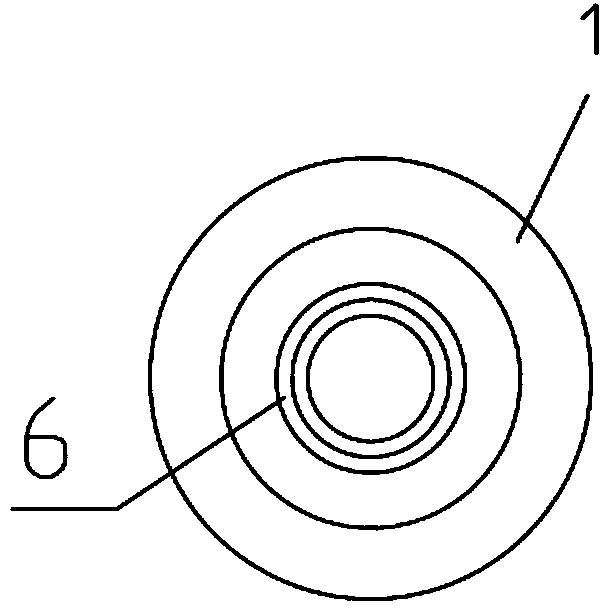

[0014] Please refer to figure 1 and figure 2 , are respectively the sectional view and the front view of the high-pressure oil injection interface and the high-pressure oil injection pipe of the present invention. The high-pressure oil injection structure of the hydrogen compressor of the BDO device includes a high-pressure oil injection interface 1 and a high-pressure oil injection pipe 2. The high-pressure oil injection pipe 1 is made of 1Cr18Ni9Ti stainless steel, and the high-pressure oil injection interface 1 is a rigid flat sealing joint. between soldered connections.

[0015] In the above-mentioned embodiment, the high-pressure oil injection interface 1 is a hollow structure, and its cross section 3 is in a convex shape, and a circular groove 6 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com