Shaft coupling mechanism and universal coupler thereof

A universal coupling and coupling technology, applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problems of low running stability, poor bearing capacity, large flat key connection gap, etc., to improve the operation The effect of smoothness, reduction in the number of bolts, and small connection gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

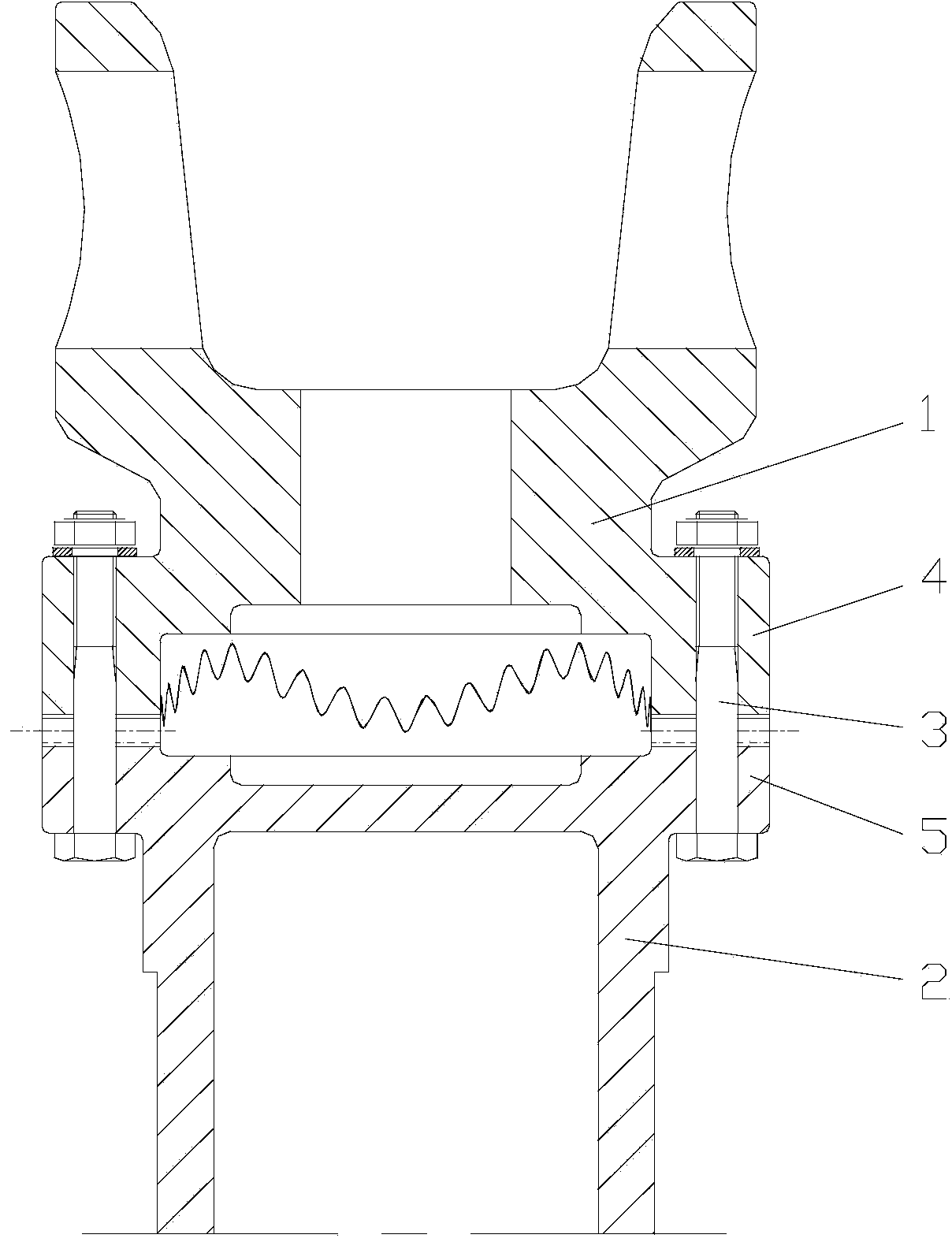

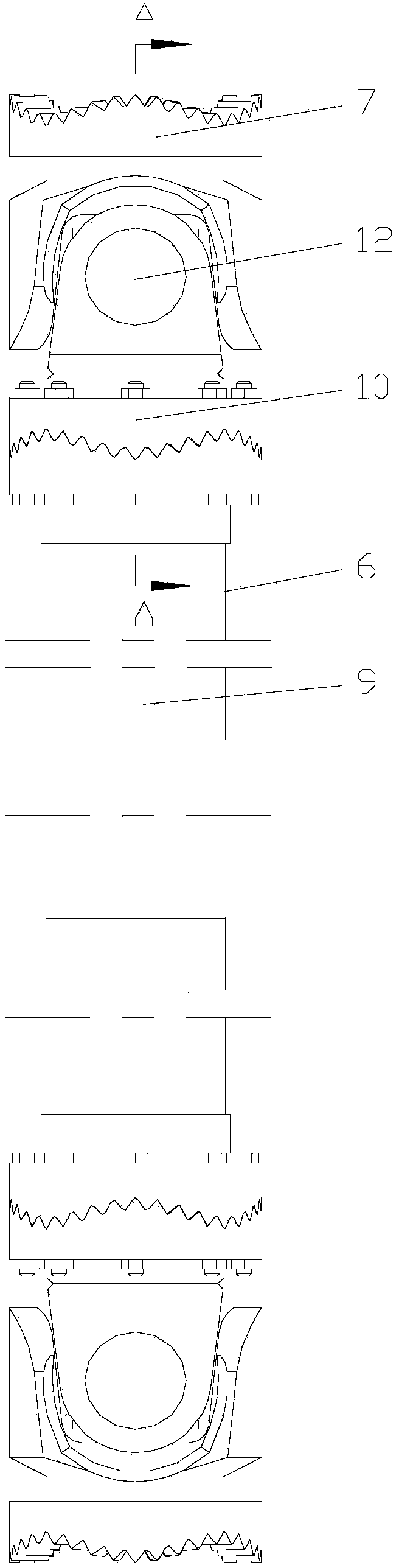

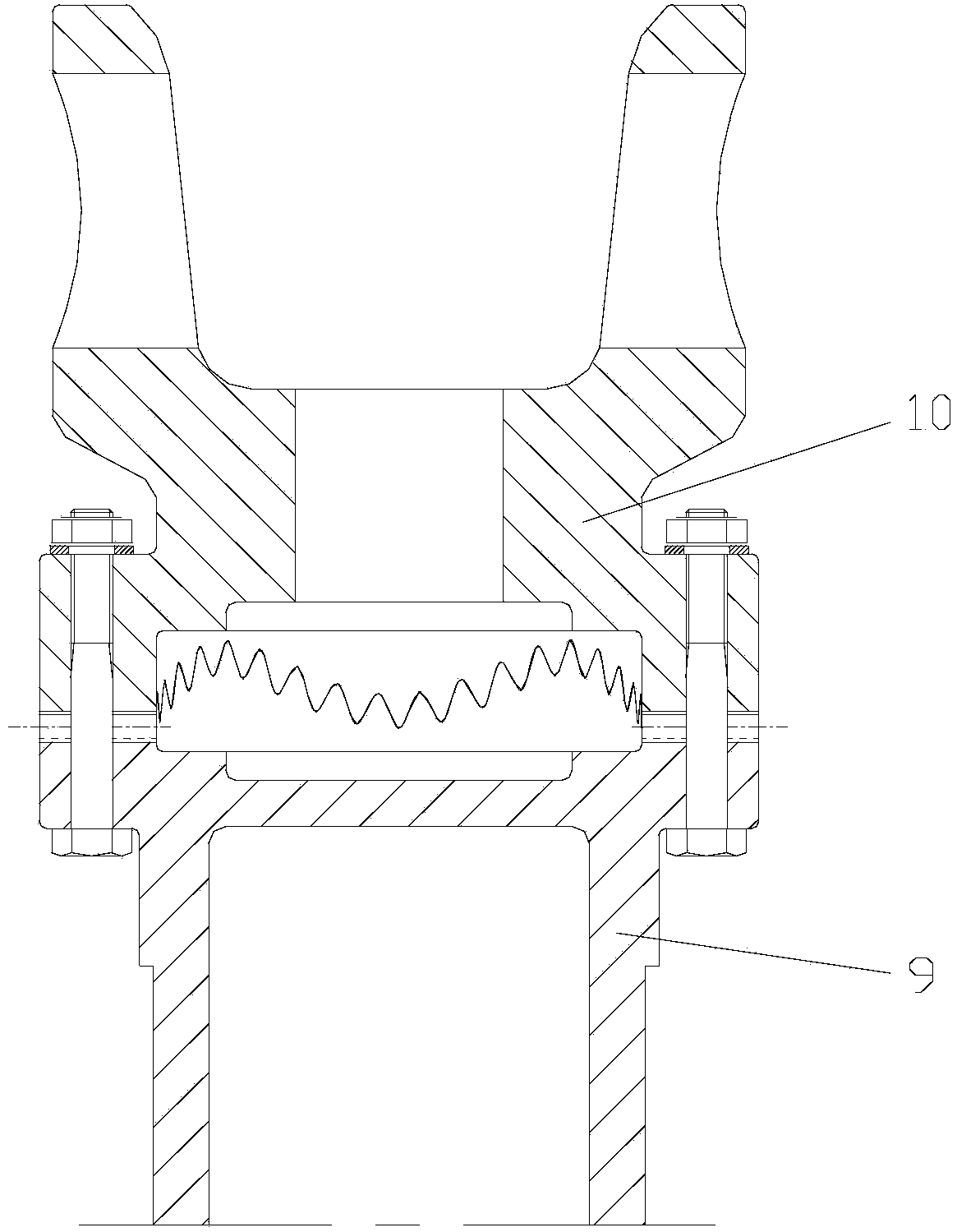

[0016] figure 1 It is a structural schematic diagram of the coupling mechanism of the present invention, figure 2 It is a structural schematic diagram of the universal joint of the present invention, image 3 for figure 2 Middle A-A sectional view, Figure 4 It is an exploded view of the universal joint of the present invention, as shown in the figure: the coupling mechanism of this embodiment includes a first rotating body 1 and a second rotating body 2 connected by end tooth meshing transmission; It is a curved end face tooth; as shown in the figure, a curved end face tooth is a kind of end face tooth whose tooth base surface forms a wave surface along the circular shear wave curve. The cooperation with the trough realizes secondary meshing and secondary centering. The contact area is large and there is a secondary load-bearing effect, which has a greater load-bearing capacity and can transmit torque greater than that of the same type of ordinary end-face gear coupling....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com