Evaporator for cooling water machine

A technology for evaporators and chillers, applied in evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of low heat exchange efficiency, difficult repair and maintenance, and large appearance of the machine, and achieve good heat exchange effect, The effect of reducing the flow distance and reducing the appearance of the overall structure of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

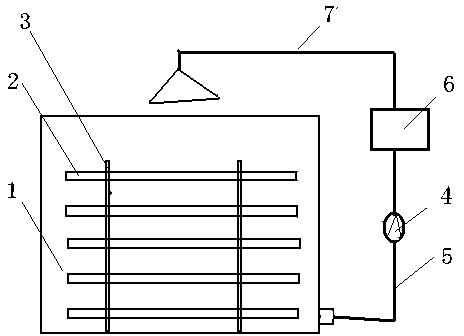

[0009] As shown in the figure, an evaporator for a water chiller is provided with a square water tank 1 with an open upper end, and copper pipes 2 are arranged in the water tank 1, and at least two rows of copper pipes are arranged in the water tank 1, and each row of copper pipes is composed of at least two copper pipes. The copper pipes 2 in the water tank 1 are positioned by at least two acrylic support plates 3, and the copper pipes 2 are connected in series with welding elbows 4, or the copper pipes can be directly bent into elbows, omitting the welding process, and the acrylic The support plate 3 arranges the copper pipes 2 in parallel with each other on the box body 1 at intervals. After being connected with the external equipment 6 by the water inlet pipe 7 above the box body, the water guide pipe 5 is provided with a water pump 4. The above-mentioned component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com