Integration method for increasing luminous power of LED

An integrated method and power technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of increasing the chip area of light-emitting diodes, reducing the number of devices, and contradicting the low cost of light-emitting diodes, so as to achieve high-power light output , Increased luminous power, solve the effect of low quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

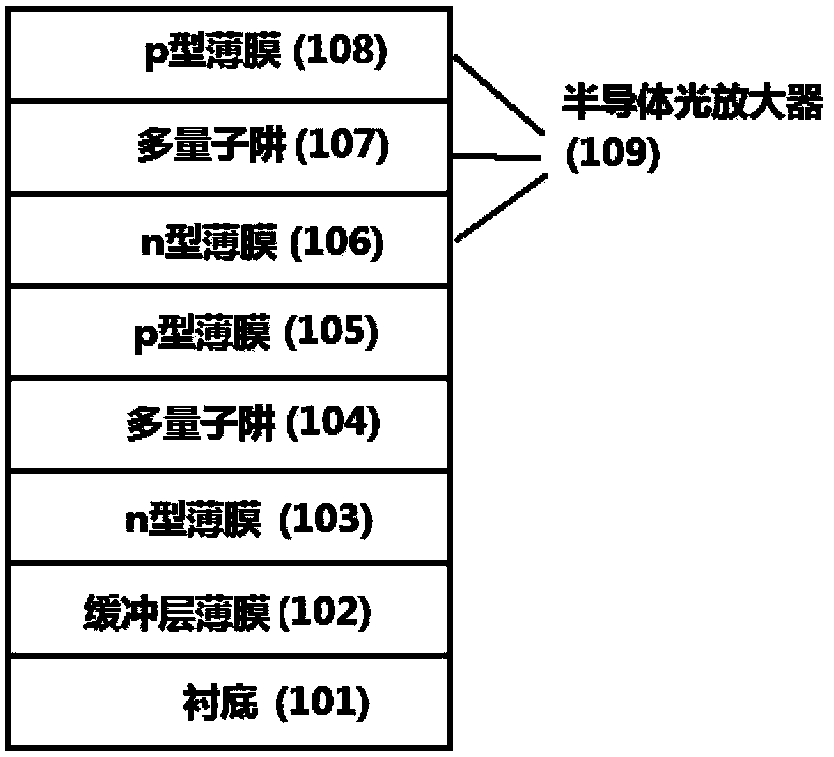

[0015] Growth of LED epitaxial thin films on metal-organic chemical vapor deposition, molecular beam epitaxy, and hydride vapor phase epitaxy equipment, see figure 1 On the substrate 101, the epitaxial buffer layer film system 102, n-type film system 103, multi-quantum well system 104, and p-type film system 105 are sequentially formed from bottom to top to form the basic LED epitaxial structure, and continue on the basic LED epitaxial structure The epitaxial n-type thin film system 106 , the multi-quantum well system 107 and the p-type thin film system 108 form a semiconductor optical amplifier 109 . The various films in the LED epitaxial film are single-layer films or multi-layer doped films or heterojunction film layers.

[0016] The film systems between the cascades, such as the p-type thin film system 105 and the n-type thin film system 106, can adopt the same gradient doping or heterojunction doping structure in order to reduce the voltage drop, improve the effective inj...

Embodiment 2

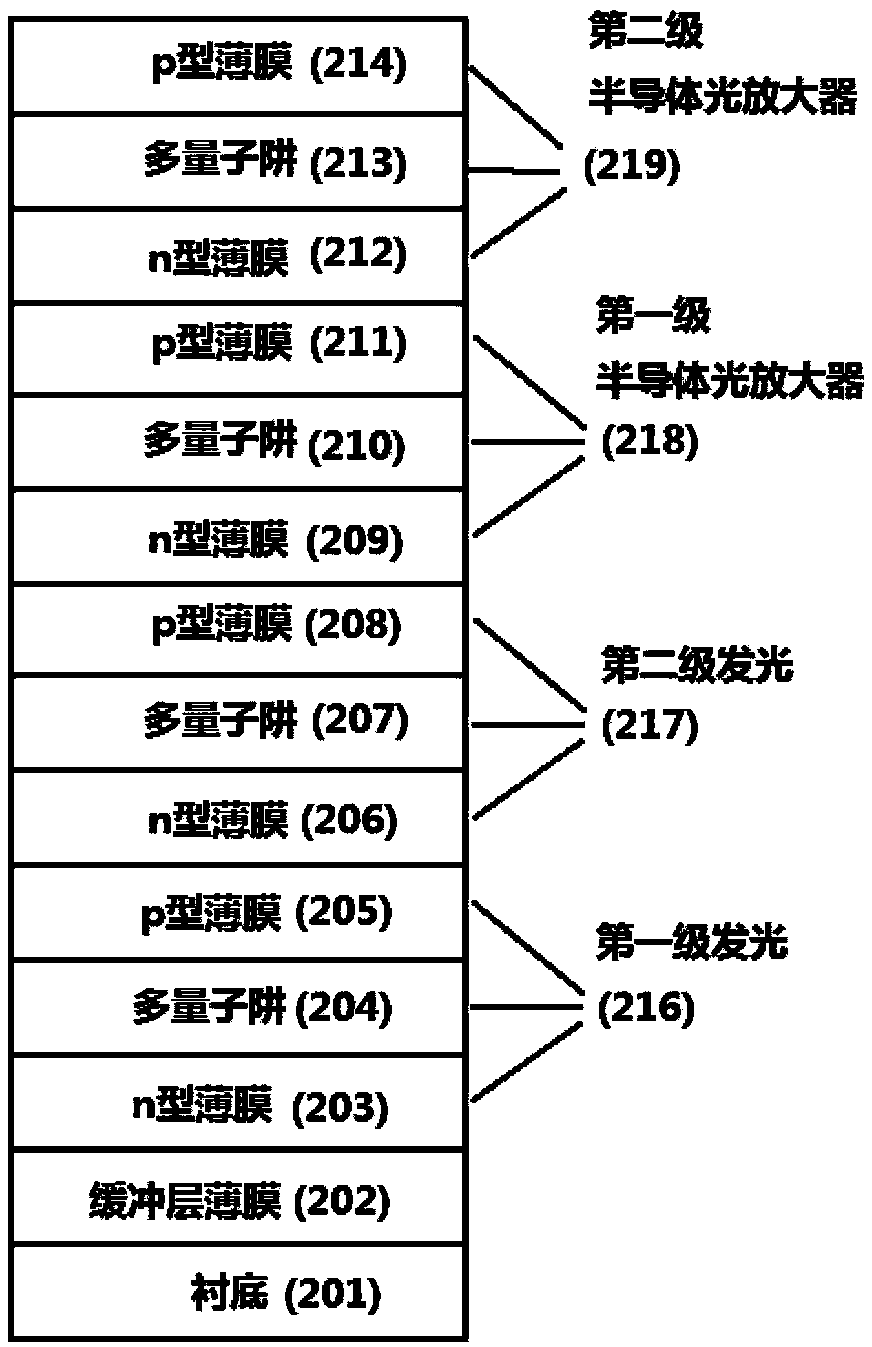

[0019] Extend the LED epitaxial film to a multi-level LED series structure. In the traditional LED chip structure, multi-section LED structures are added along the epitaxial growth direction, such as figure 2 As shown on the substrate 201, from bottom to top, epitaxial buffer layer film system 202, n-type film system 203, multi-quantum well system 204, p-type film system 205, n-type film system 206, multi-quantum well system 207, p-type film system Thin-film system 208, n-type thin-film system 209, multiple quantum well system 210, p-type thin-film system 211, n-type thin-film system 212, multiple quantum well system 213, p-type thin-film system 214, wherein n-type thin-film system 203, multiple quantum well system 204 and p-type thin film system 205 form the first-level light-emitting unit 216, and the n-type thin-film system 206 above the first-level light-emitting unit 216, the multi-quantum well system 207 and the p-type thin-film system 208 form the second-level light-em...

Embodiment 3

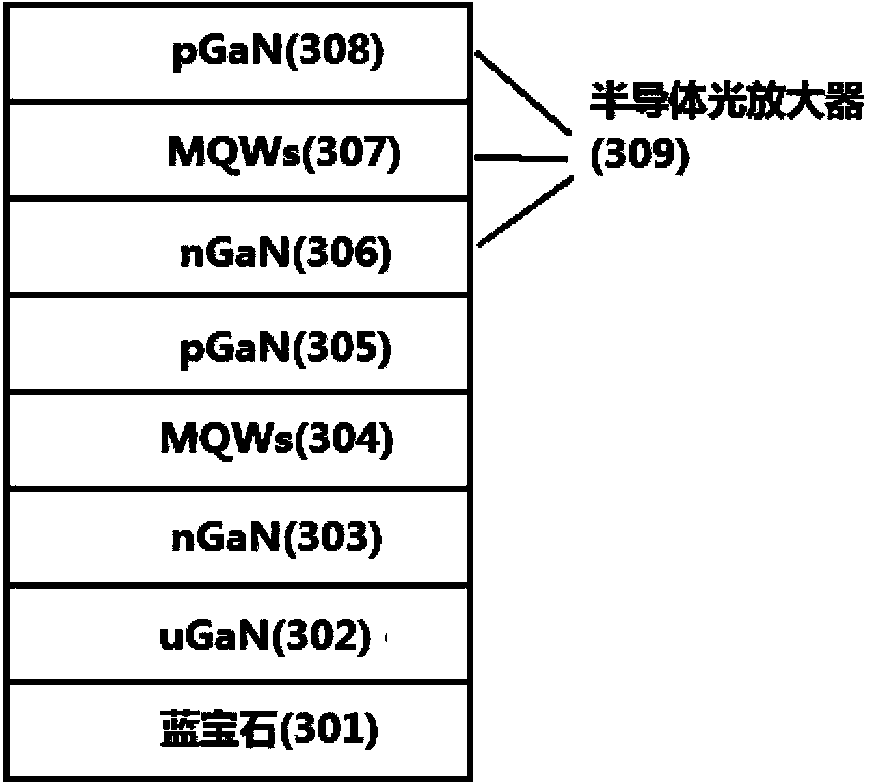

[0022] Embodiment three is the same as embodiment one, the difference is as follows image 3 As shown, the blue GaN-based LED epitaxial film is grown on the sapphire substrate of this embodiment, and uGaN302, nGaN303, InGaN-based MQWs304, pGaN305, nGaN306, InGaN-based MQWs307, and pGaN308 are epitaxially grown on the sapphire 301 from bottom to top. Among them, nGaN306, MQWs307 and pGaN308 form a semiconductor optical amplifier. The basic principle of increasing the luminous power of the LED is that the light emitted by the InGaN-based MQWs304 passes through the semiconductor optical amplifier and is amplified by stimulated radiation, thereby increasing the luminous power of the LED.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com