Method for detecting initial position of rotor of power robot

A technology of rotor initial position and detection method, which is applied to the control of generators, motor generators, electromechanical brakes, etc., and can solve problems such as unreliability, reduced accuracy, and dangerous lines of electric robots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings.

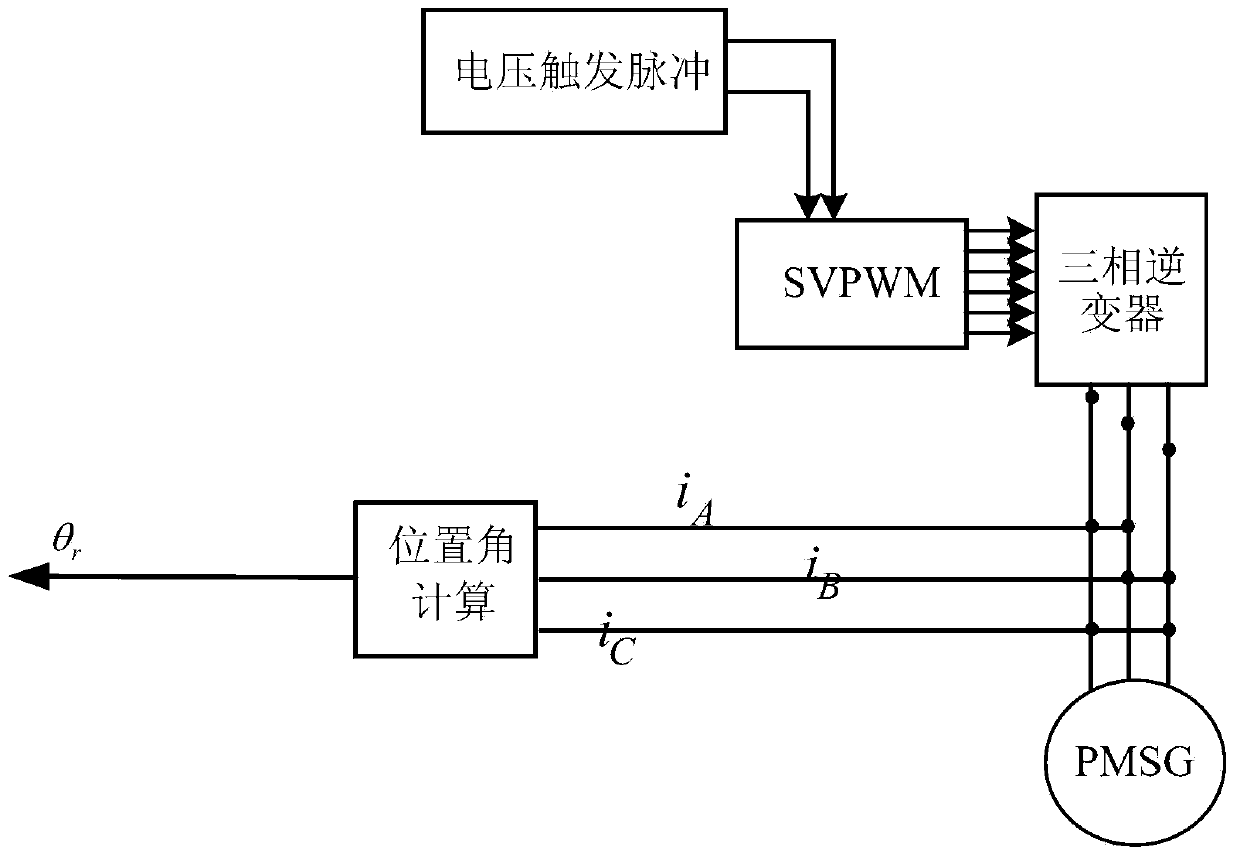

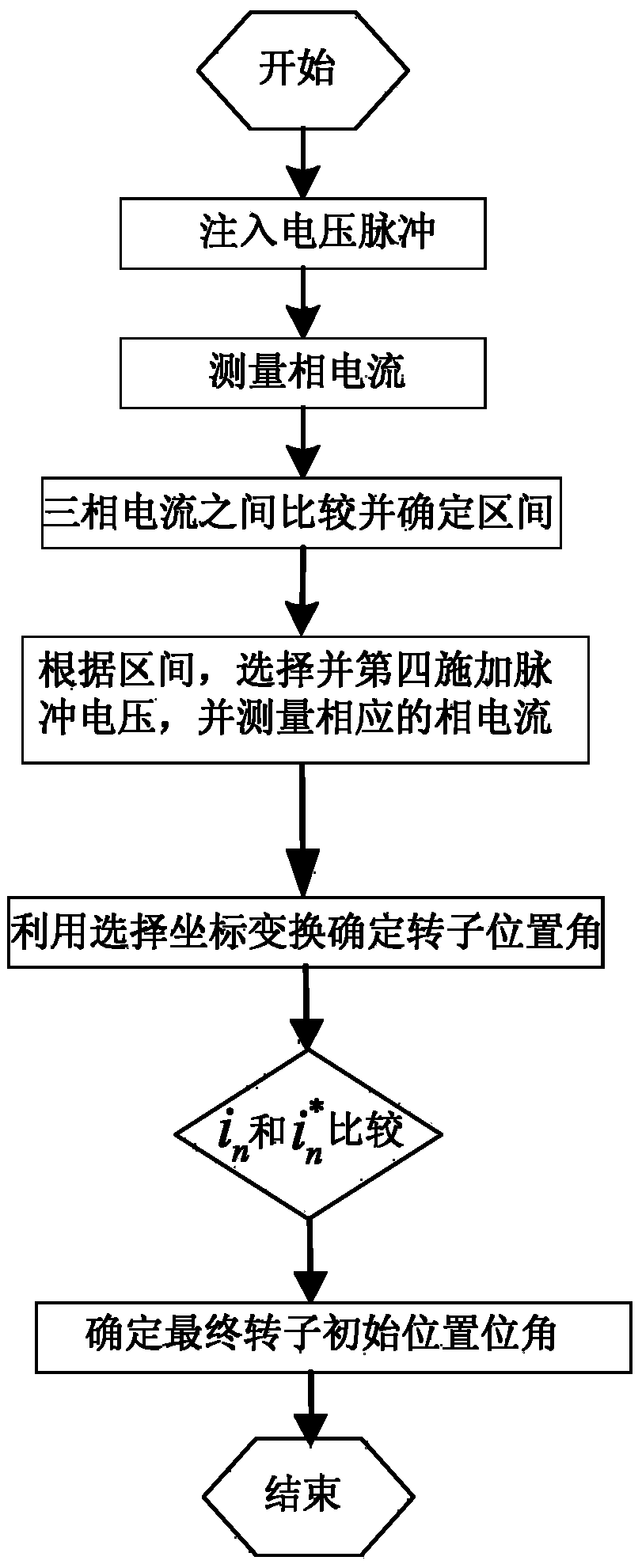

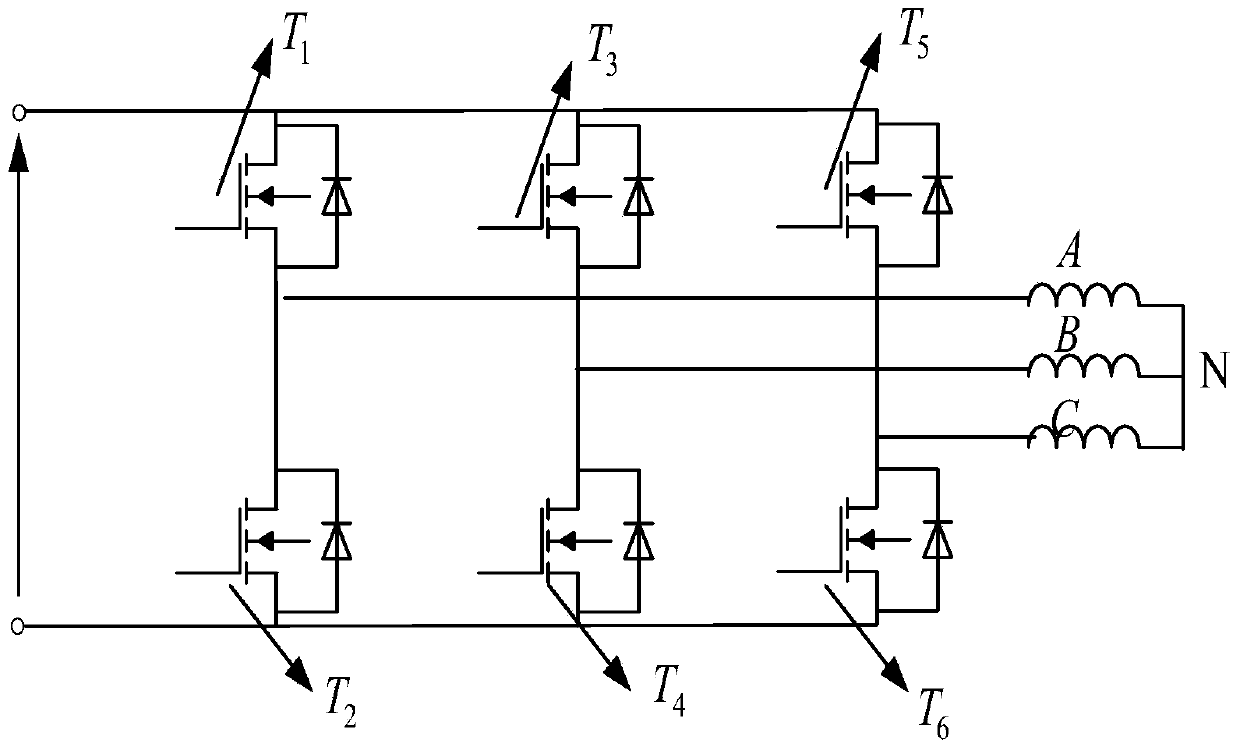

[0050] The method for detecting the initial position of the rotor of an electric robot first applies three different voltage pulses to the permanent magnet motor by controlling the three-phase inverter (drive circuit), according to figure 1 Detect the phase current response peak values of phase A, phase B, and phase C respectively, and after comparing the phase current response peak values of the three phases, preliminarily determine the range of the rotor position angle; then according to the range of the rotor position angle, control the three-phase The inverter applies a voltage pulse relative to the interval to the permanent magnet motor, and at the same time detects the corresponding peak current and compares it with the current peak value obtained from the previous three detections. During the four current peak detection processes, the optimal three detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com