Graphical detection display method for real-time monitoring of grinding state

A technology of real-time monitoring and grinding status, which is applied in the direction of grinding machine parts, grinding/polishing equipment, workpiece feed movement control, etc., can solve the problems of low work efficiency, achieve high work efficiency, novel structure, The effect of ensuring accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

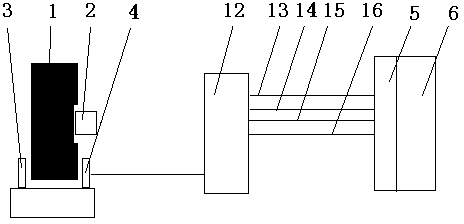

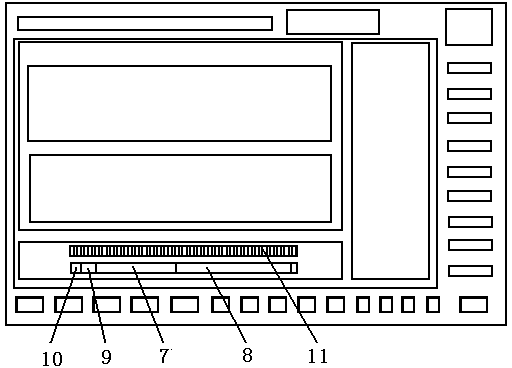

[0012] As shown in the accompanying drawings, a graphical detection and display method for real-time monitoring of the grinding state includes a sonar measurement system, a PLC controller 5 and a numerical control system 6, and is characterized in that the sonar measurement system includes a sonar sensor 2, Receiver 3, transmitter 4 and signal processing unit 12, the sonar sensor 2 is preferably installed in the main shaft of the grinding wheel 1, the transmitter 4 and receiver 3 are symmetrically installed on the accessory brackets on both sides of the main shaft of the grinding wheel 1, and The distance from the main shaft is 0.5~1mm, so that the ultrasonic waves detected by the transmitter 4 and the receiver 3 are in the range of 250~350KHZ at the reciprocating telemotion frequency of the grinding wheel 1, and a sufficient noise spectrum space is generated to distinguish the noise From the rotating contact of the grinding wheel 1 and the workpiece or from other external fact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com