Plate vacuum sucking device and method thereof for hoisting plate

A suction device and vacuum suction cup technology, which is applied in transportation and packaging, object supply, pile separation, etc., can solve the problems of high surface quality requirements for adsorption plates, inability to absorb plates, and lack of automatic cleaning functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

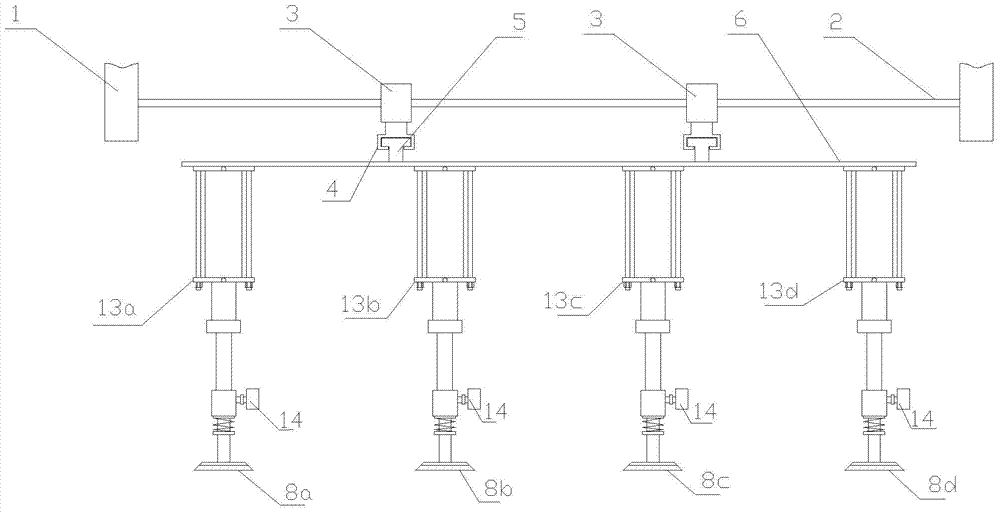

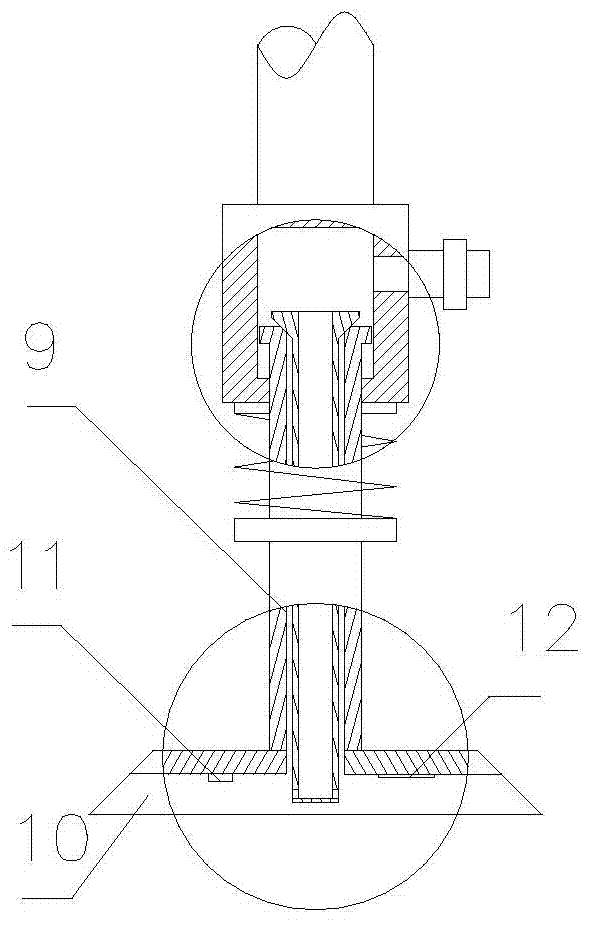

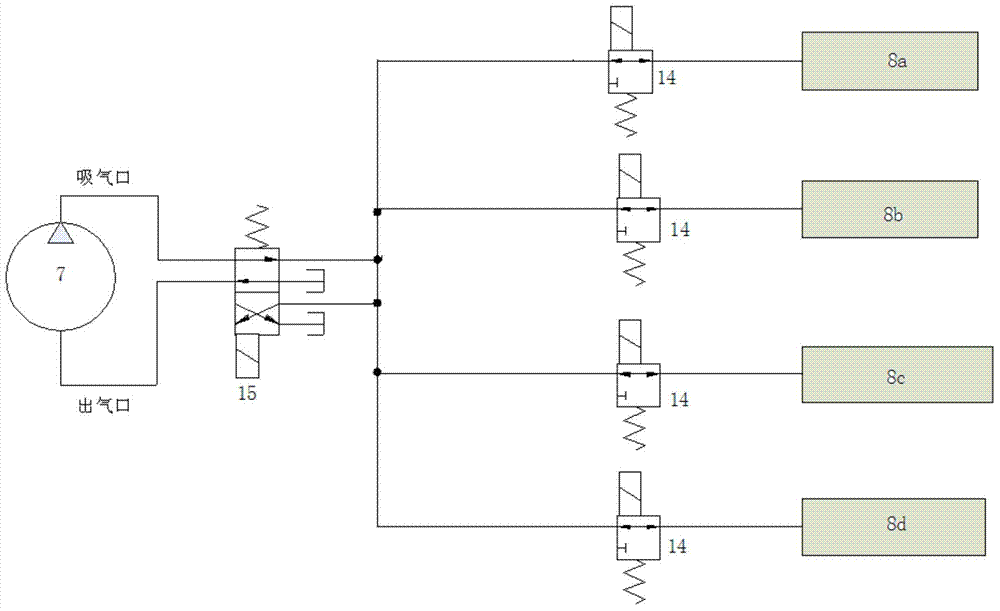

[0032] Such as Figure 1-3 As shown, a plate vacuum suction device includes a PLC (not shown in the figure) and a conveying guide rail 2 arranged on a frame 1, a conveying slider 3 is stuck on the conveying guide rail 2, and a conveying slider 3 is provided on the lower surface of the conveying slider 3. There is an adjustment guide rail 4, an adjustment slider 5 is stuck on the adjustment guide rail 4, and an installation base 6 is arranged on the bottom of the adjustment slider 5. The bottom surface of the installation base 6 is vertically arranged in parallel with four columns of hydraulic cylinders 13a, 13b, 13c, 13d controlled by PLC. , 8c, 8d. The vacuum suction cups 8a, 8b, 8c, 8d include a suction cup mount 9 connected to the bottom of the piston rod of the hydraulic cylinder, the suction cup mount 9 is provided with a gas channel, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com