A kind of rubber composition and tire shoulder rubber and preparation method thereof

A rubber composition and composition technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the improvement results of rolling resistance, wet skid resistance, heat generation and aging resistance, monomer Vinylpyridine is expensive and tire manufacturing costs are high, and it achieves good mixing process performance, dynamic mechanical properties, environmental protection, and low processing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

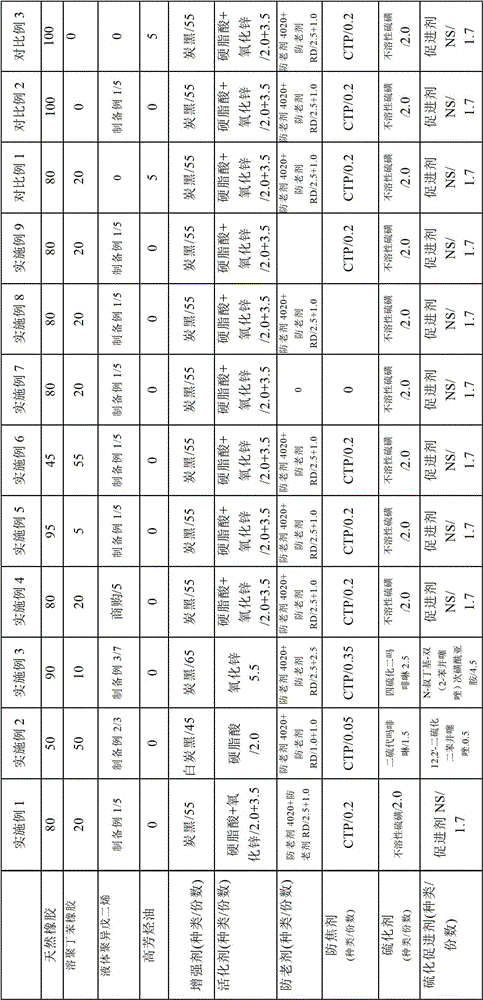

Examples

preparation example 1

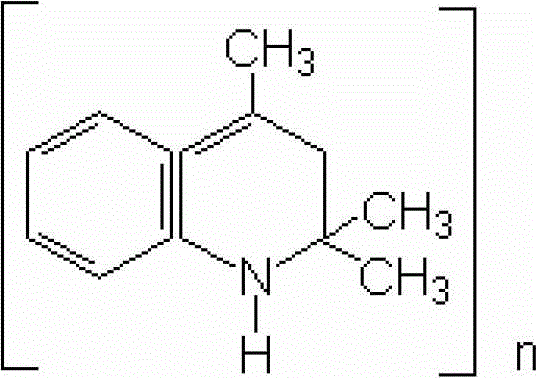

[0083] This preparation example is used to illustrate the liquid isoprene and its preparation method according to the present invention.

[0084] Polymerization was carried out in a 5L polymerization reactor. After the polymerization system is replaced by high-purity nitrogen, 200g of isoprene monomer and 1800g of dry cyclohexane are added to the polymerization reactor in sequence, and deionized water is added to the polymerization reactor under stirring, and the stirring is continued for about 10 minutes and heated to 40°C, and then add 15.8mL of n-butyllithium n-hexane solution with a concentration of 0.3M at this temperature to start the polymerization reaction. During the polymerization reaction, the temperature is controlled within the range of 40-50°C, and the polymerization reaction The pressure in the kettle was controlled at 0.1-0.3 MPa (gauge pressure), and the polymerization was carried out for 120 minutes. Wherein, the molar ratio of deionized water to organic lit...

preparation example 2

[0086] This preparation example is used to illustrate the liquid isoprene and its preparation method according to the present invention.

[0087] The same method as Preparation Example 1 was used to polymerize isoprene, except that the molar ratio of deionized water to organolithium initiator was 2:100. As determined by weighing method, the conversion of isoprene was 100%. The prepared liquid polyisoprene was characterized and the results are shown in Table 1.

preparation example 3

[0089] This preparation example is used to illustrate the liquid isoprene and its preparation method and application according to the present invention.

[0090] The same method as Preparation Example 1 was used to polymerize isoprene, except that the molar ratio of deionized water to organolithium initiator was 4:100. As determined by weighing method, the conversion of isoprene was 100%. The prepared liquid polyisoprene was characterized and the results are shown in Table 1.

[0091] Table 1

[0092]

[0093] It can be seen from the results in Table 1 that in the liquid polyisoprene prepared by the method of the present invention, the content of structural units formed by 1,4-polymerization of isoprene is high, which can reach more than 96.9 mol % ( Under optimal conditions, it can reach more than 97 mole %); the molecular weight distribution of the prepared liquid polyisoprene is relatively narrow, and can reach below 1.11 (under optimal conditions, it can reach below 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap