A fast drying kiln for soft wood and its drying method

A fast drying and soft technology, which is applied in the direction of drying solid materials, local agitation dryers, and static material dryers, etc., can solve the problems of general drying effect, wood drying defects, and long drying cycle, so as to speed up the drying speed, Effect of preventing drying defects and improving drying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

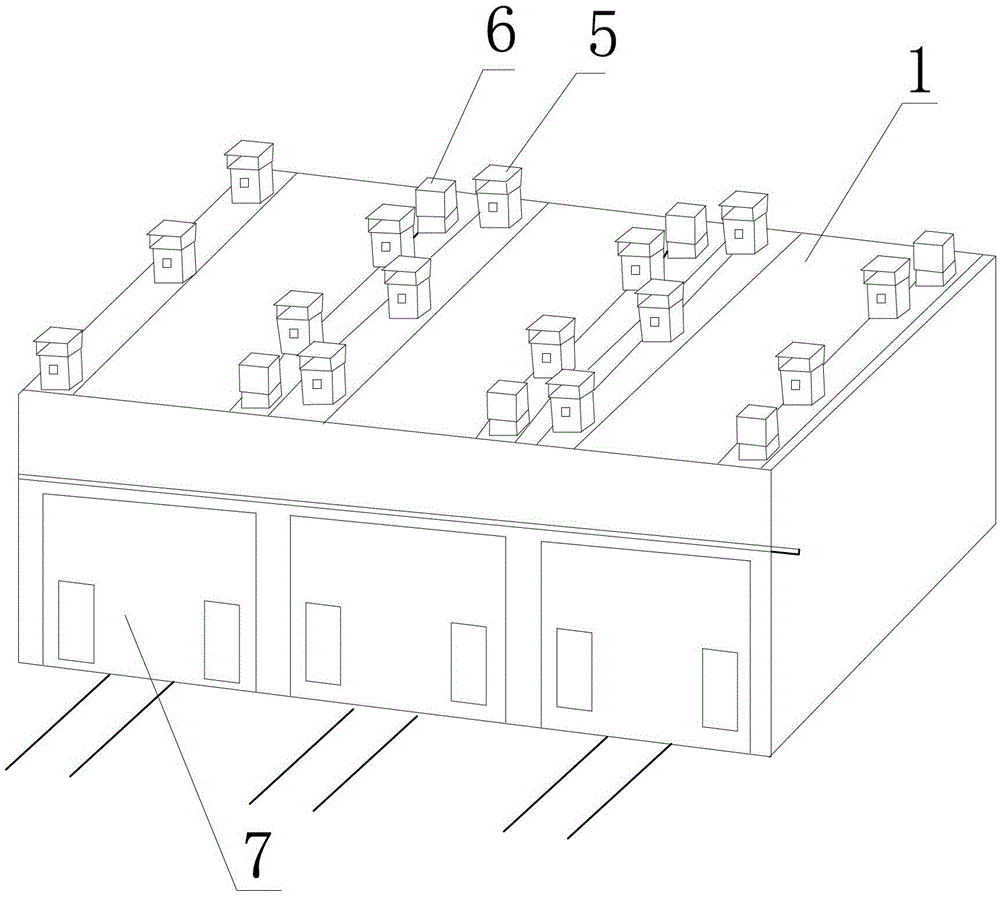

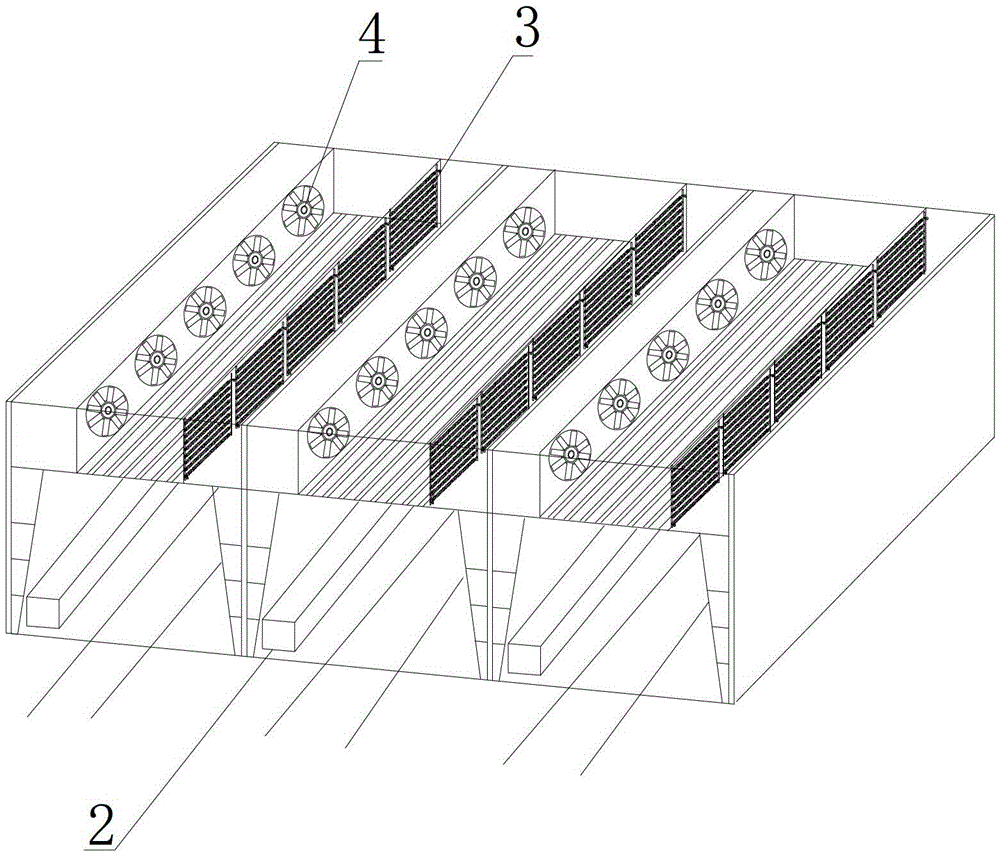

[0027] as attached Figure 1~2 As shown, the soft wood rapid drying kiln of the present invention includes a kiln body 1, a fan 4, a heater 3 and an evaporation water tank 2 are arranged in the kiln body 1, and a moisture discharge window 5 is arranged on the top for removing humid air in the kiln body. , the top of the kiln body is also provided with an explosion-proof window 6, which is used to adjust the pressure difference formed when the fan is started, so as to prevent the pressure difference in the kiln body from being too large and damage the kiln body. The fan 4 is a fan with a diameter of 1.8 meters. The rapid drying kiln of the present invention also includes a control system, which is used to control the opening and closing of each electric control component and control parameters such as time and temperature of each stage. A kiln door 7 is arranged on the side of the kiln body for feeding materials.

[0028] The method for quickly drying soft wood with the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com