Experimental test device for fire spread behavior of thermoplastic material

A thermoplastic material and testing device technology, which is applied in the direction of using combustion for chemical analysis, can solve the problems of increasing fire risk and the rate of fire spread, and achieve repeatable operation, overcome material size limitations, and flexible use of devices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

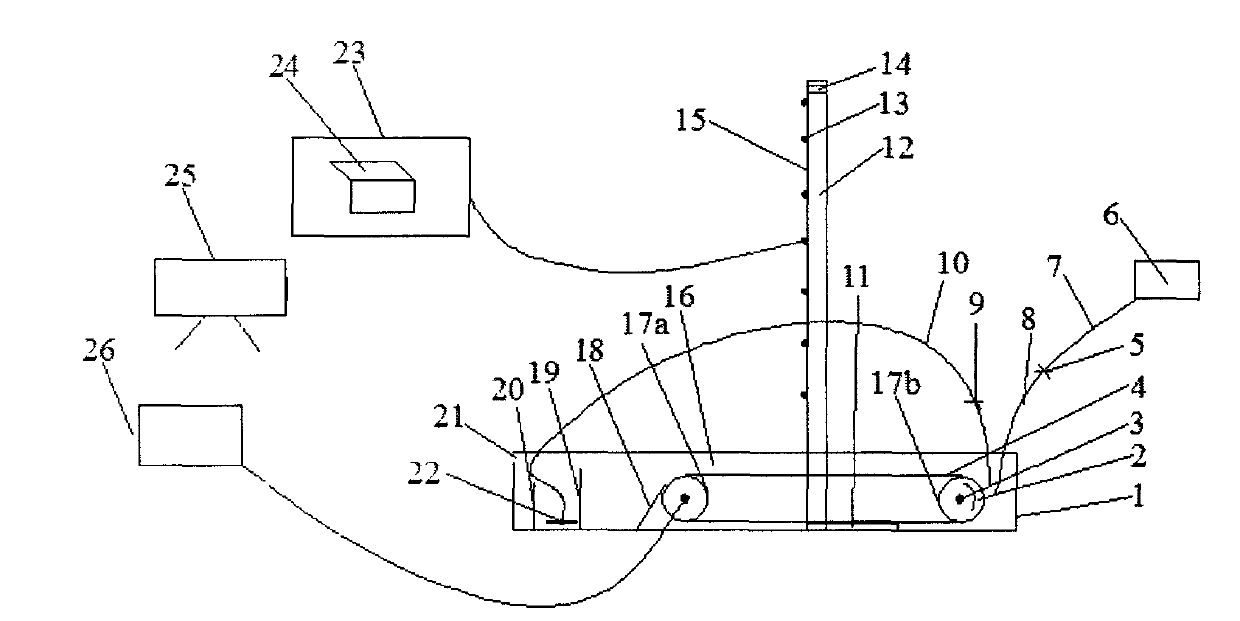

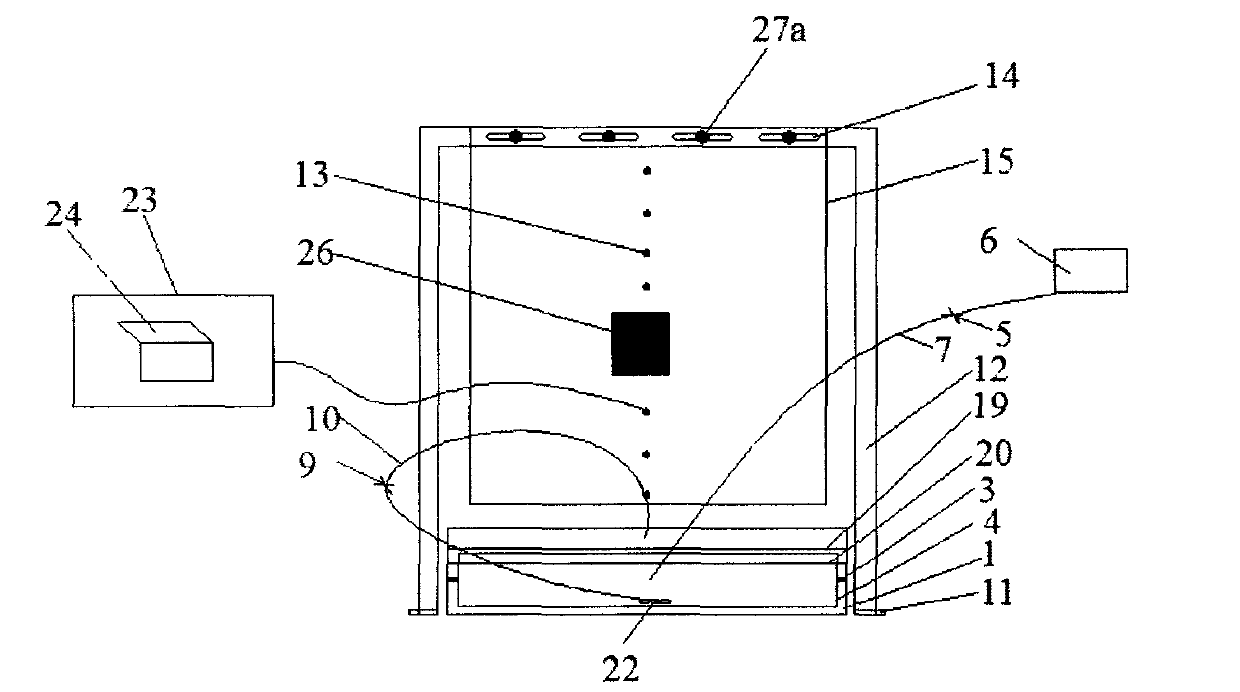

[0014] figure 1 It is a front view of a thermoplastic material fire spread rate experimental testing device of the present invention; figure 2 It is a side view of the experimental device of the present invention. As shown in the above-mentioned accompanying drawings, a kind of thermoplastic material fire spread rate experimental testing device of the present invention comprises sample support 12, molten liquid solidification system 16 and measurement and control system 23; Described sample support 12 is frame structure, adopts stainless steel, surface Apply fireproof paint, the width of each side of the frame is 3cm, the overall width and height are 1.5m × 2.0m, the bottom of the frame is supported by a base 11, and the base 11 extends 40cm to two directions perpendicular to the sample holder 12, to ensure that it is installed Measure the stability of the sample holder 12 of the sample 15, the surface of the upper frame of the sample holder 12 has a through installation hol...

Embodiment 2

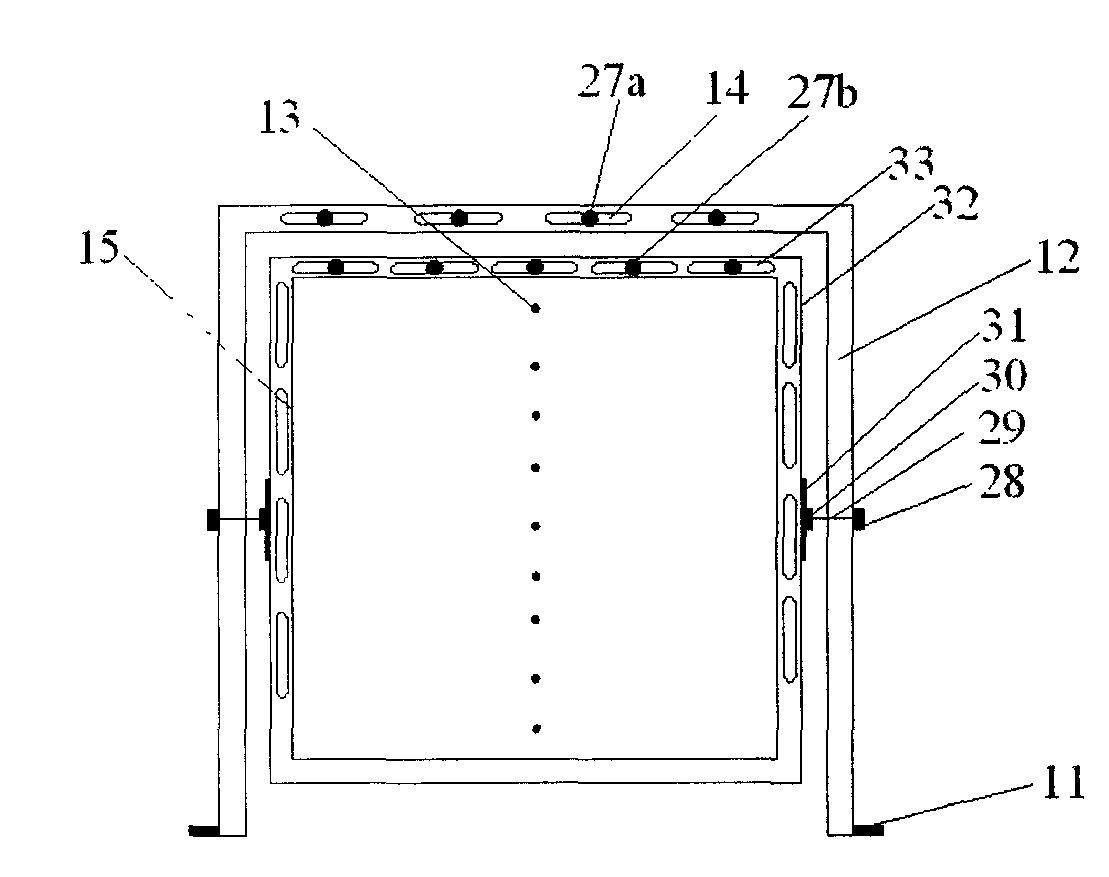

[0017] image 3 It is a front view of the sample holder structure in Example 2; Figure 4It is a side view of the sample support structure in embodiment 2; in the present embodiment, the tested sample 15 is an XPS extruded plastic board, and a sample frame 32 is added inside the sample support 12, and there are fixing holes 33 on the upper part of the sample frame 32 and the left and right side edges, The size of the sample frame 32 is 1.6m×1.0m. The left and right sides of the sample frame 32 are connected to the sample holder 12 by connecting rods 29. The sample frame 32 can rotate along the connecting rod 29. The fixing button 30 on the board can fix the sample frame 32 at a certain angle, and the sample frame 32 is provided with an angle recorder 31 near the connecting rod 29 to record the angle of the measured sample 15; the fixing holes 33 are long strips with a width of 1 cm and an interval of 1 cm Arrangement, using screws 27b to fix the tested sample 15 on the sample...

Embodiment 3

[0019] In this embodiment, a quartz heat shield is added at a position 6mm away from the surface of the tested sample 15 on the side of the tested sample 15 facing the partition b20, and the infrared thermal imager and the video camera are arranged parallel to the sample surface with a distance of 2m and a height of The other settings are the same as in Embodiment 1; this embodiment can simulate the behavior of flame spread on the surface of thermoplastic materials in the slit.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com