Multi-beam laser condensation transmission device

A transmission device and laser technology, applied in the direction of condenser, light guide, optics, etc., can solve the problems of high manufacturing cost, inability to meet engineering needs, poor focusing effect of multiple laser beams, etc., and achieve the effect of low cost, simple structure and easy molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

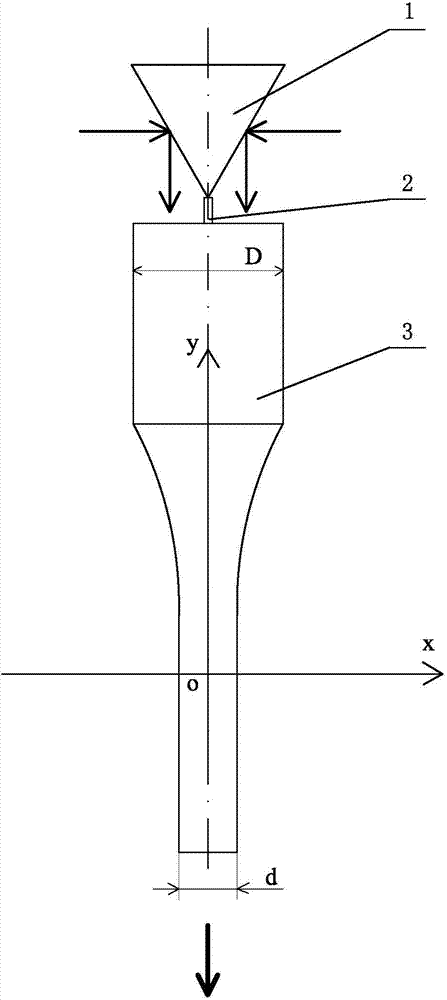

[0016] exist figure 1 Among them, the multi-beam laser focusing and transmitting device of this embodiment is composed of a reflective pyramid 1, a pillar 2, and a laser transmitting and focusing rod 3 connected together.

[0017] The cone tip of reflective pyramid 1 is bonded to the central position of support 2 with optical glue, and the other end of support 2 is bonded to the central position of the light incident end face of laser transmission focusing rod 3 with optical glue, and the centerline of the cone of reflective pyramid 1 Coinciding with the center line of the laser transmission focusing rod 3, the reflective pyramid 1 is made of crown glass (H-K9). The reflective pyramid 1 in this embodiment is a regular quadrilateral pyramid, and the apex angle of each side of the regular quadrangular pyramid is 45°. The side of the reflective pyramid 1 is a laser reflective surface, and the side is coated with an aluminum reflective film. The reflective pyramid 1 is used to ref...

Embodiment 2

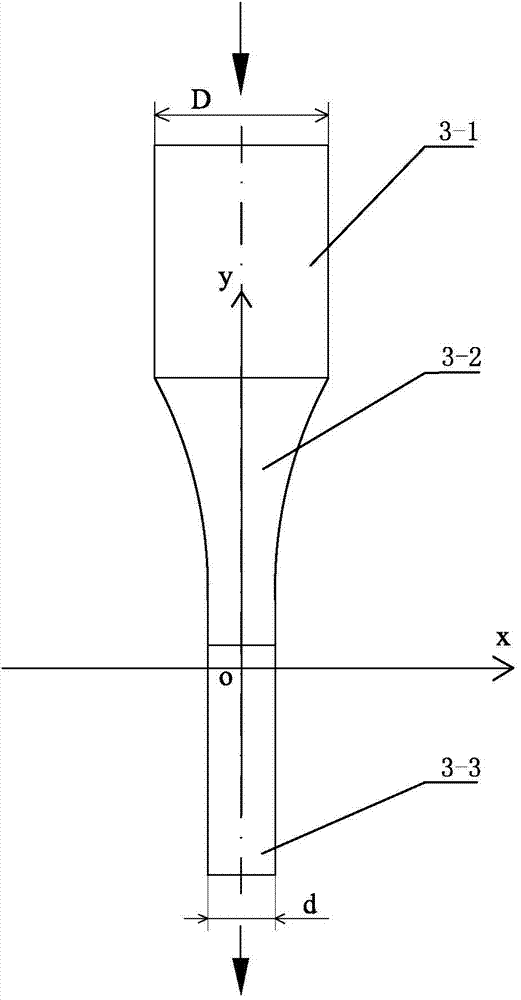

[0023] The geometric shape of the laser transmission focusing rod 3 in this embodiment is as follows: the light incident end of the light focusing section 3-2 is connected as a whole to form a laser transmission section 3-1, and the light emitting end of the light focusing section 3-2 is connected as a whole to form a The optical adjustment section 3-3 constitutes a laser transmission hyperbolic focusing rod, the geometric shape of the laser transmission section 3-1 is a cylinder with a diameter D of 10.5mm, and the geometric shape of the optical adjustment section 3-3 is a cylinder with a diameter d of 1.5mm Cylinder, that is, D is equal to 7d, and the geometric shape of the light-focusing section 3-2 is a body of revolution whose side is a hyperboloid. The y-axis is the hyperbolic surface of revolution formed by the rotation of the central axis, and the hyperbolic equation is the same as the hyperbolic equation (1) of embodiment 1. In the hyperbolic equation, x is the radius ...

Embodiment 3

[0025] The geometric shape of the laser transmission focusing rod 3 in this embodiment is as follows: the light incident end of the light focusing section 3-2 is connected as a whole to form a laser transmission section 3-1, and the light emitting end of the light focusing section 3-2 is connected as a whole to form a whole. Optical section 3-3 constitutes a laser transmission hyperbolic focusing rod, the geometric shape of laser transmission section 3-1 is a cylinder with a diameter D of 15mm, and the geometric shape of the whole light section 3-3 is a cylinder with a diameter d of 1.5mm , that is, D is equal to 10d, and the geometric shape of the light-concentrating section 3-2 is a body of revolution with a hyperbolic surface on the side. It is the hyperbolic surface of revolution formed by the rotation of the central axis, and the hyperbolic equation is the same as the hyperbolic equation (1) of embodiment 1. In the hyperbolic equation, x is the radius variable of the light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com