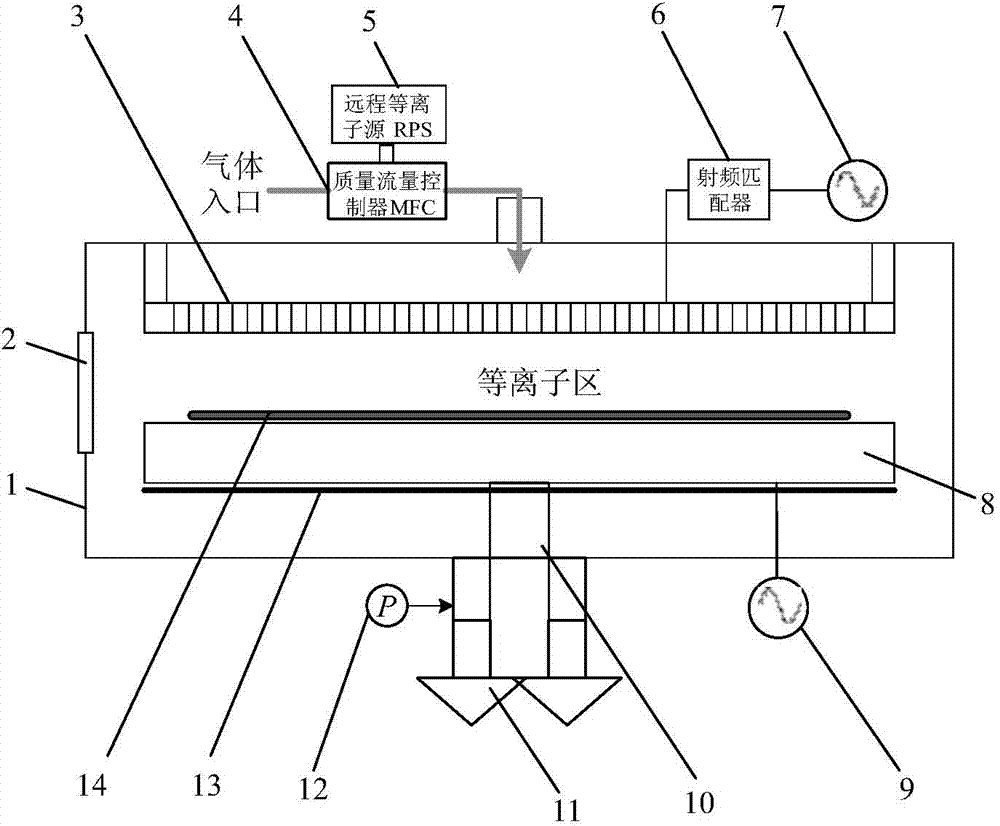

Heating plate capable of fast and fine adjusting space distribution of temperature field and control method thereof

A technology of spatial distribution and temperature adjustment, which is applied in the direction of temperature control using electric methods, auxiliary controllers with auxiliary heating devices, gaseous chemical plating, etc. Fine-tuning of quality space distribution, poor adjustment and correction ability and other problems, to achieve rapid and fine-grained regulation, enhanced stability and compatibility, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

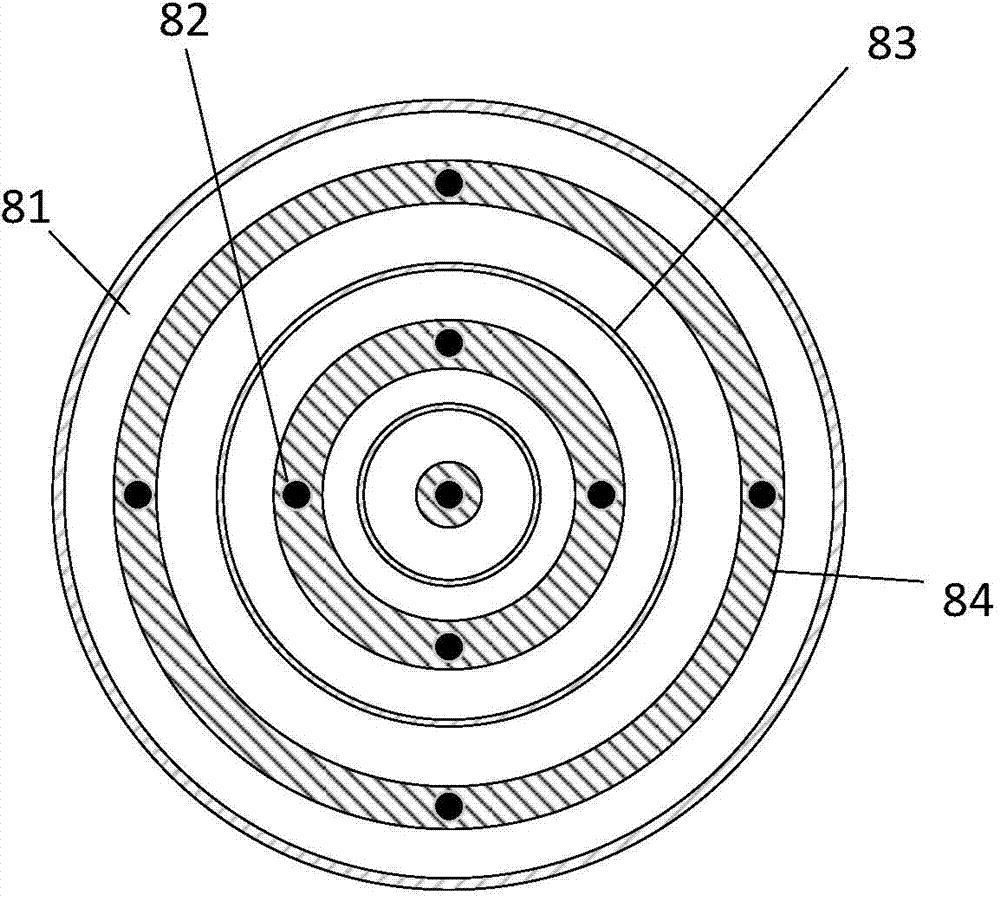

[0033] figure 2 with Figure 4 It is a schematic diagram of the first embodiment of the heating plate 8, which realizes the flexible control capability and fine control of the temperature spatial distribution.

[0034] The feature of the heating plate 8 is that the originally integrated metal base 81 of the heating plate is divided into several heat-insulating parts by the heat insulating layer 83 . The heat insulating layer 83 has two or more annular structures, and divides the heating plate 8 into annular areas with different diameters. Through the heat insulating layer, the thermal diffusion effect between adjacent areas is reduced, making the control between different areas more independent.

[0035] A temperature sensor 82 is arranged inside the metal base body 81 of the heating plate and in the area of each insulating belt. The temperature sensors 82 are arranged in a ring array, and each ring has 4 or more. The temperature sensor 82 may be a thermocouple sensor or...

Embodiment 2

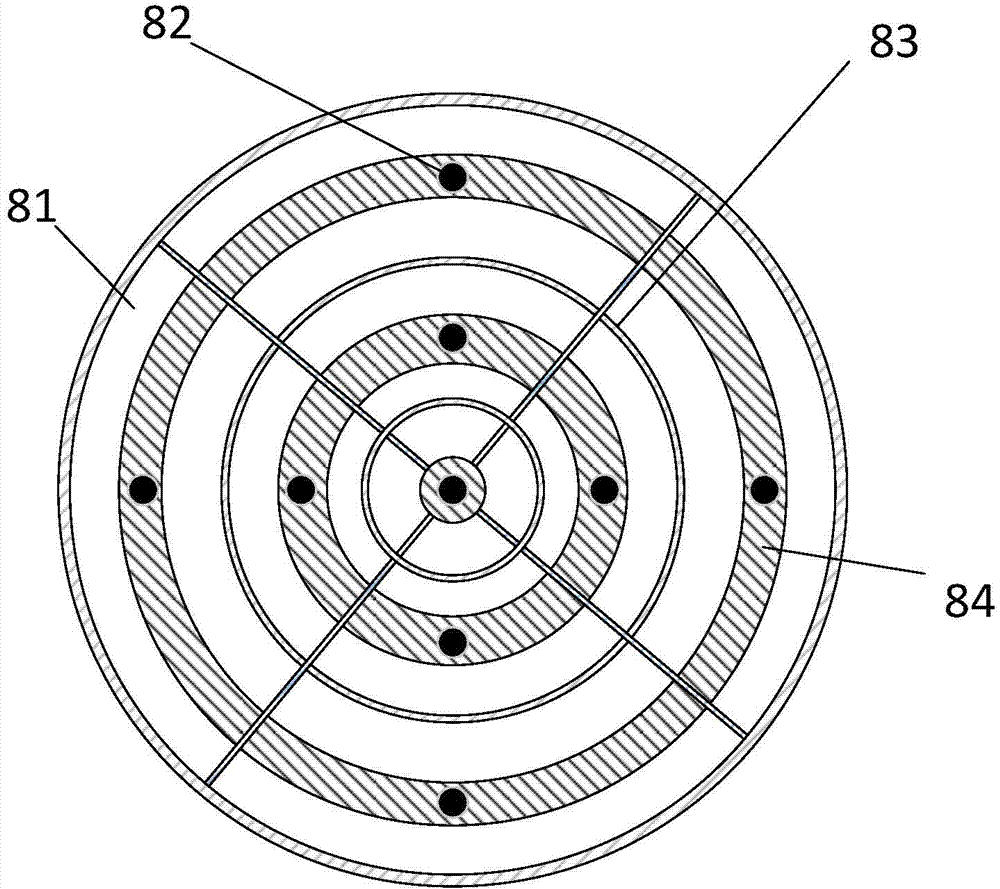

[0048] image 3 with Figure 4 It is a schematic diagram of the second embodiment of the present invention. Compared with Example 1, in addition to the ring-shaped heat insulation layer, several linear heat insulation layers are also set along the diameter direction, and the heat insulation belt Divide into several fan-shaped areas for finer control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com