Carrying platform for wafer-level ball mounter

A wafer-level, platform-based technology, applied in the manufacture of electrical components, electrical solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of unstable mechanism, low degree of automation, and low positioning accuracy, so as to improve the degree of automation and improve production Efficiency, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

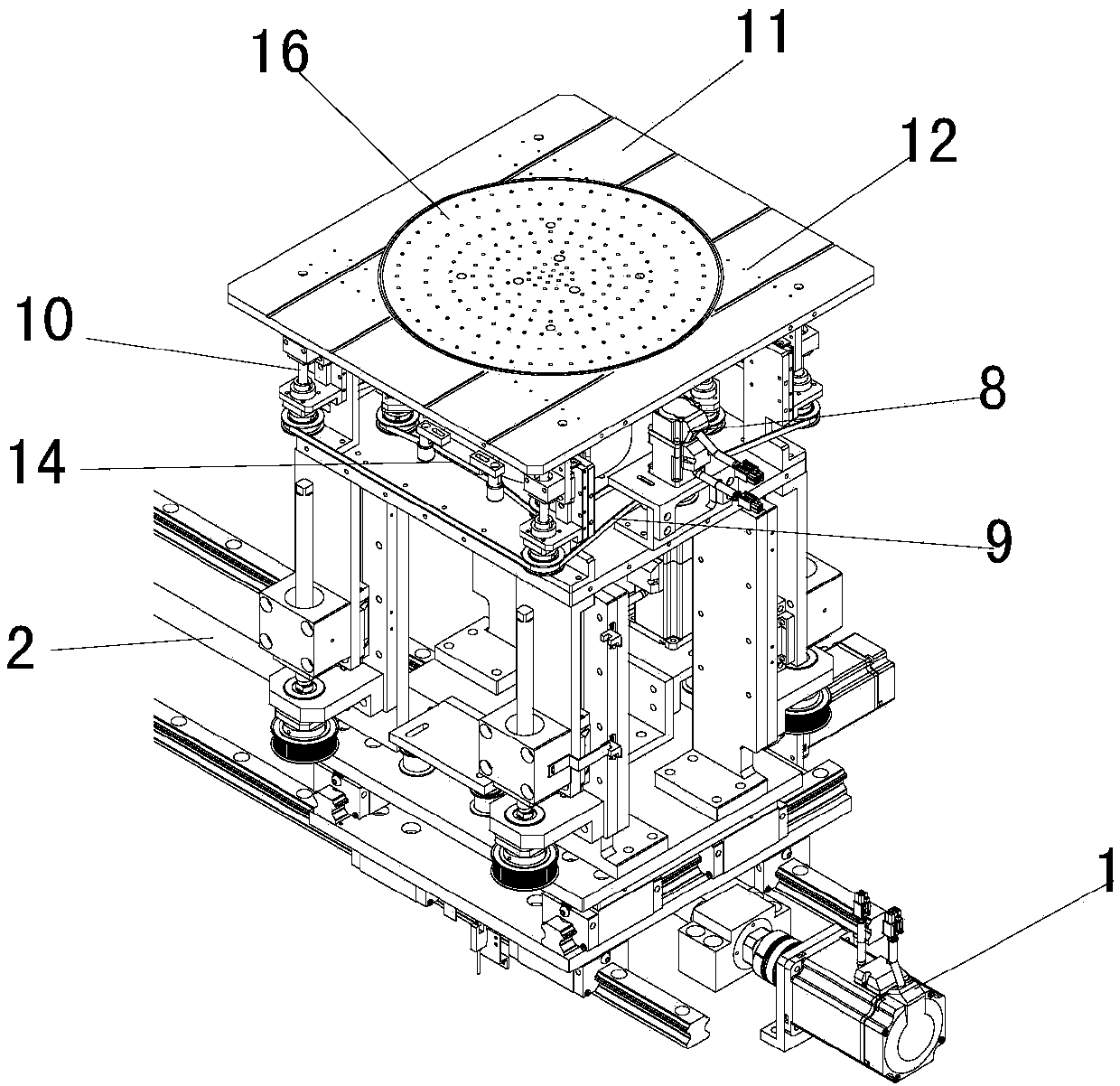

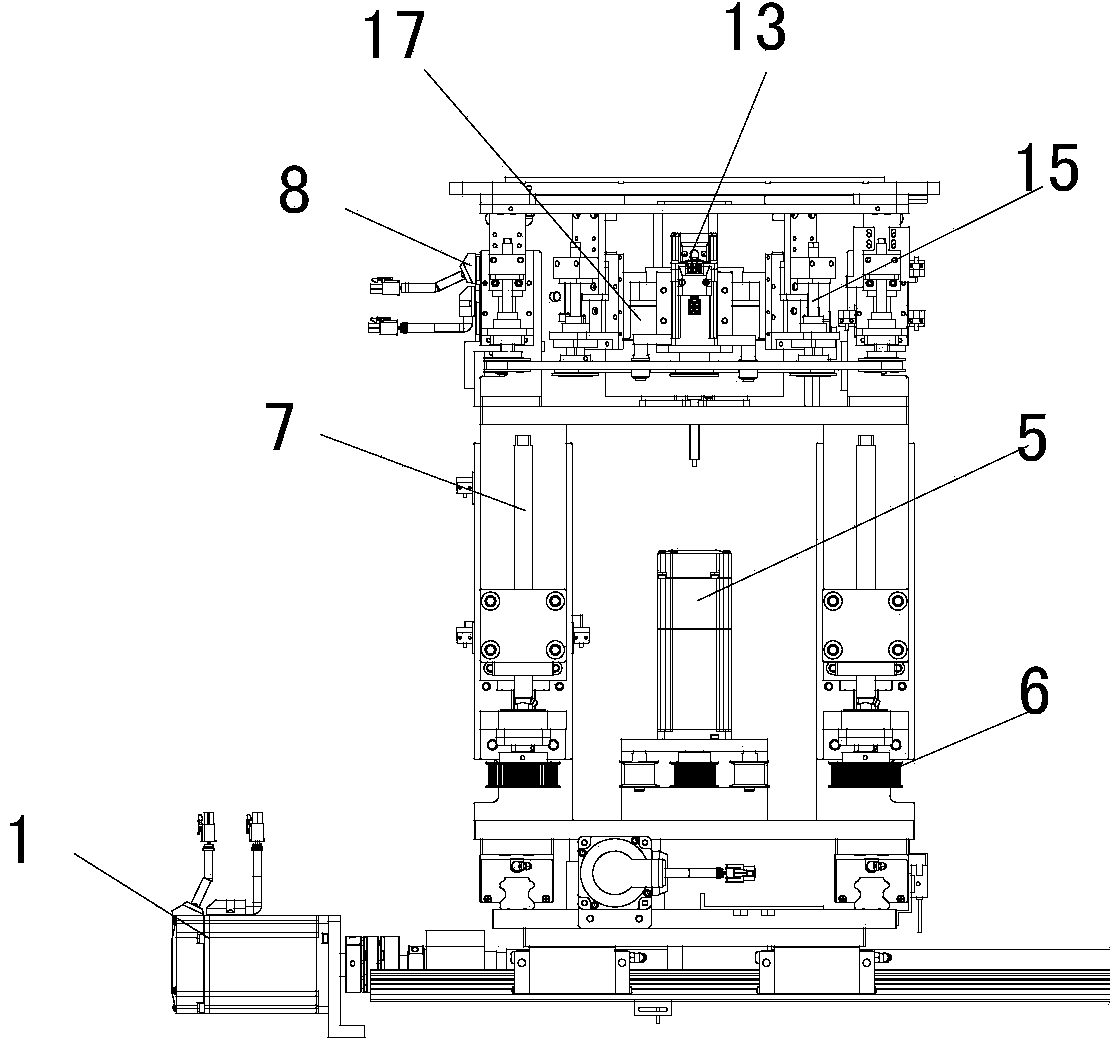

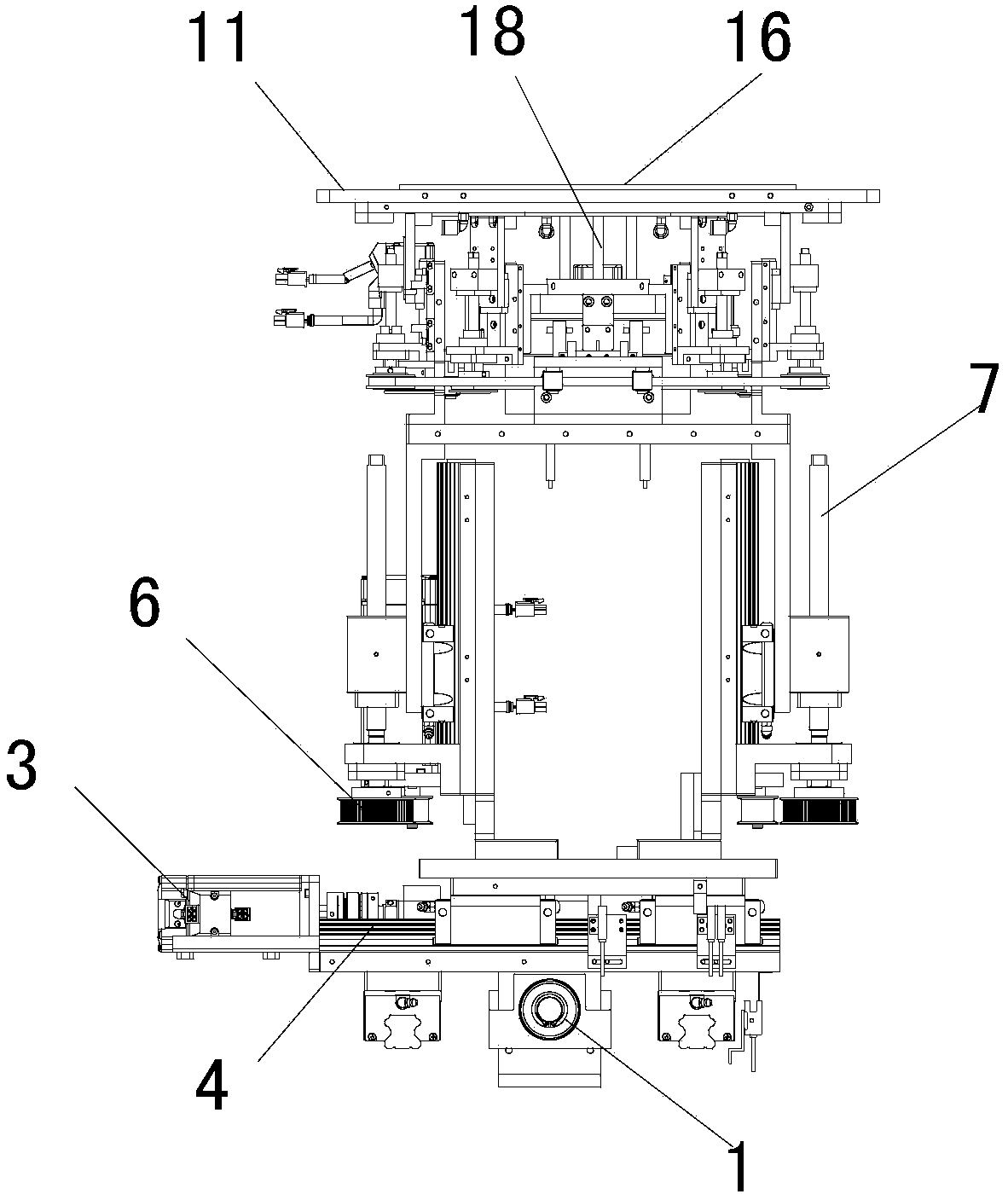

[0023] see figure 1 , figure 2 , image 3 , the mounting platform for wafer-level ball planting machine of the present invention includes a bottom X-axis motion system, a bottom Y-axis motion system, a bottom Z-axis motion system, an outer ring Z-axis motion mechanism, an inner ring Z-axis motion mechanism, a crystal Circular support column, carrying platform outer ring and carrying platform inner ring. The above-mentioned bottom X-axis motion system, bottom Y-axis motion system, bottom Z-axis motion system, outer ring Z-axis motion mechanism, and inner ring Z-axis motion mechanism are respectively driven by servo motors and precision screw drives. The inner ring 16 of the carrying platform and the wafer support column 18 are respectively provided with vacuum adsorption holes. Figure 12 shows the vacuum suction holes arranged on the outer ring 11 of the loading platform.

[0024] The bottom X-axis motion system includes the X-axis drive motor 1 and the X-axis drive screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com