A rail transit non-contact power supply device with honeycomb coil and power supply method thereof

A non-contact power supply and rail transit technology, applied in the direction of circuit devices, electrical components, etc., can solve the problems of low magnetic field utilization rate, small effective induction area, low magnetic field strength, etc., achieve high magnetic field utilization rate, reduce electromagnetic radiation, improve The effect of distribution density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

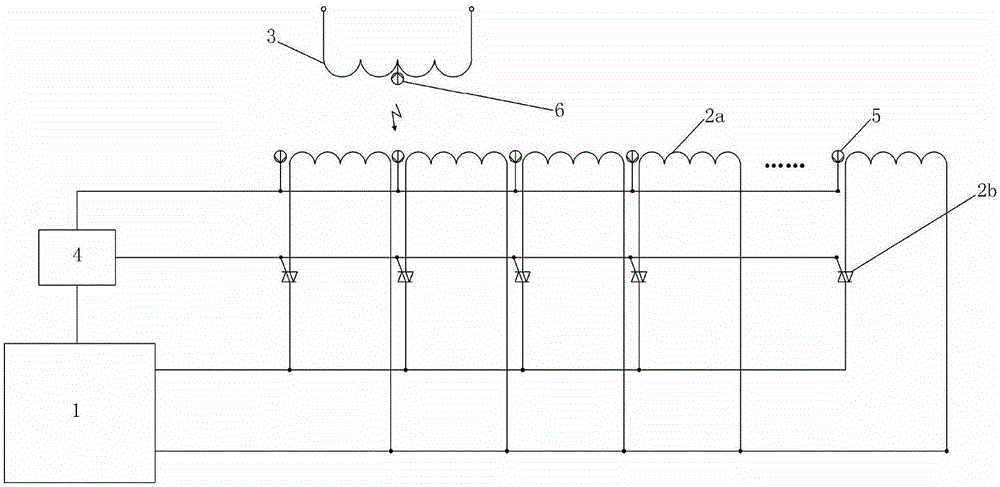

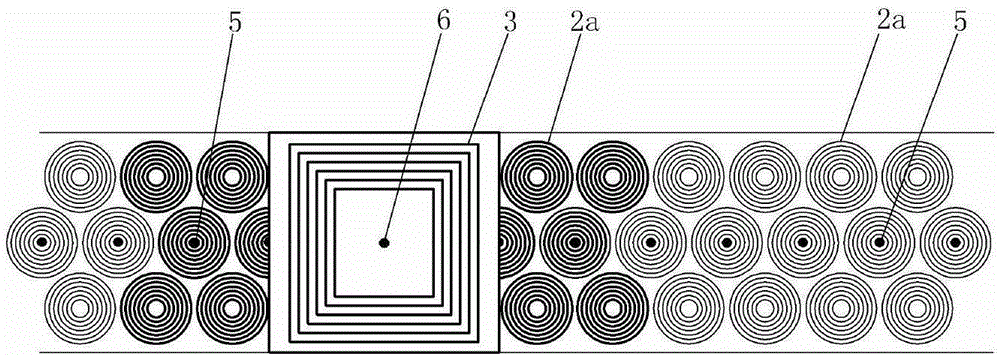

[0021] Figure 1-3 It shows a specific embodiment of the present invention, a rail transit non-contact power supply device with cellular coils, including a pick-up coil 3 at the bottom of the locomotive, a controller 4 of the power supply station, a controller 4 and AC-DC-AC frequency conversion 1, and the AC-DC-AC converter 1 is connected with the power supply coil buried under the surface of the track power supply section at the same time. Small power supply coils 2a are connected in parallel, each small power supply coil 2a is connected in series with a switch tube 2b, and the control end of the switch tube 2b is connected to the controller 4; the distance between every other small power supply coil 2a on the center line of the track power supply section is set A signal receiver 5 for detecting the pickup coil 3, the signal receiver 5 is also connected to the controller 4; the pickup coil 3 is provided with a signal generator 6.

[0022] The method of using the rail transi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com