Deaerator system and method for deaeration

A control system, bubble technology, applied in degasser systems and in the field of degassing, to achieve the effect of improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

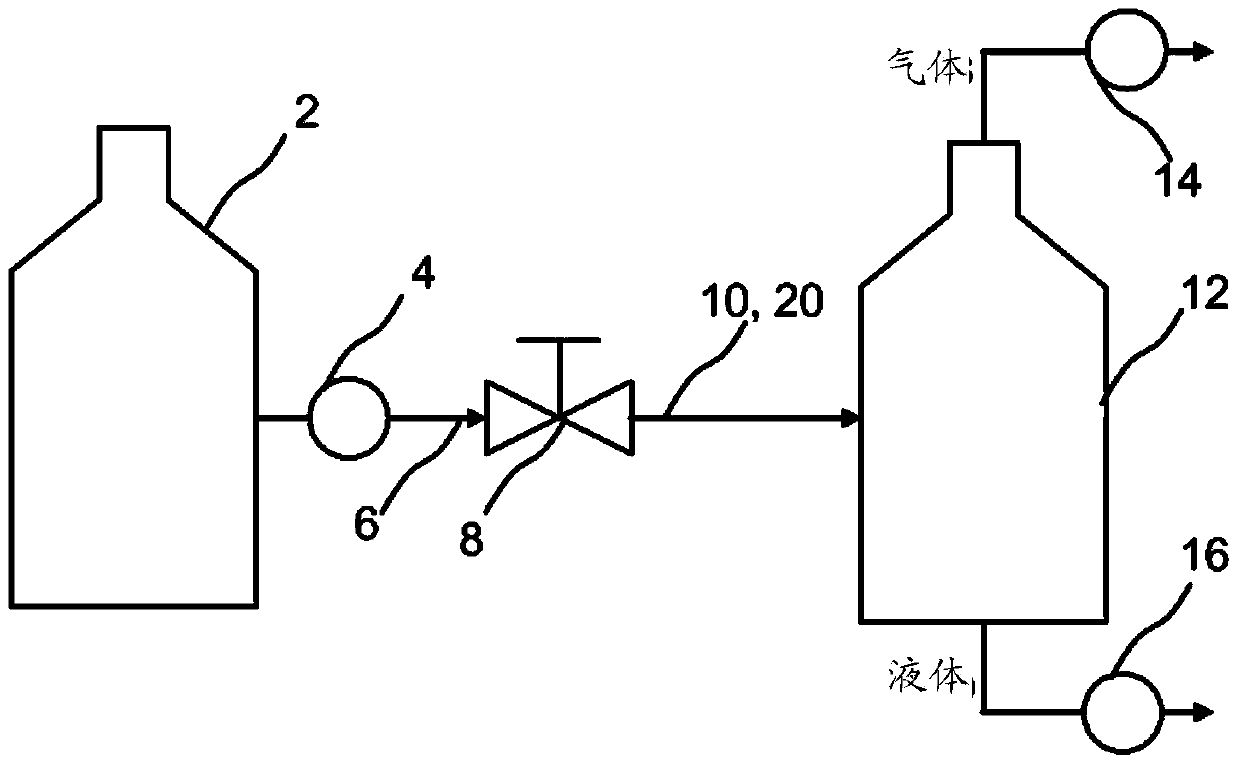

[0026] will refer to figure 1 Portions of a system for handling liquids are described. The invention may form part of such a system, but individual components may be replaced without departing from the scope of the invention as defined by the claims.

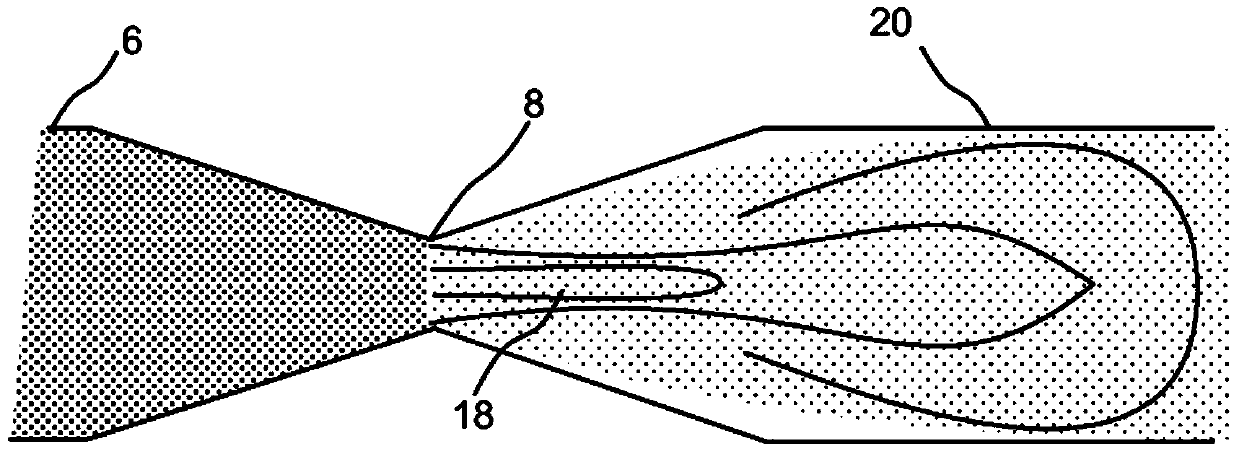

[0027] From an upstream location, the system includes a storage tank 2 or other system for containing or conveying the liquid to be treated. The system also includes a pump 4 for raising the pressure of the liquid so that the liquid is subjected to an elevated static pressure P 上游 , in order to force it to flow downstream. Pump 4 may in one or more embodiments be a centrifugal pump, however other alternatives are also possible. Conduit 6 leads the liquid to the first processing step, ie to nucleation valve 8 . Before describing the details of the valve, a few words should be said about the arrangement downstream of the valve. A line 10 leading the liquid after the nucleation valve 8 opens into a separation vessel 12 . In t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com