Biodegradation-based epoxy ethane waste gas treatment method and system

A technology for the treatment of ethylene oxide and waste gas, which is applied in the direction of gaseous effluent wastewater treatment, separation methods, chemical instruments and methods, etc., and can solve the difficult, difficult, large environmental hazards and safety of the harmless treatment of ethylene oxide waste gas stress and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

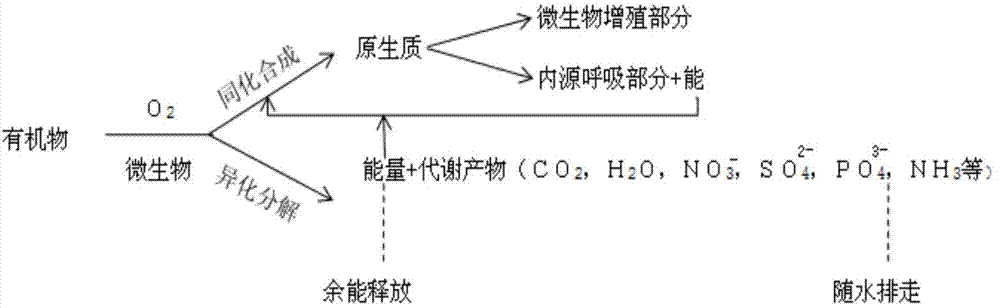

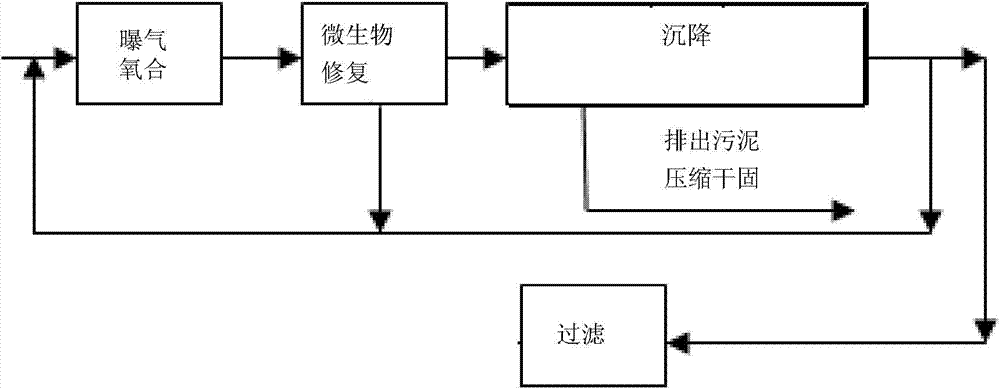

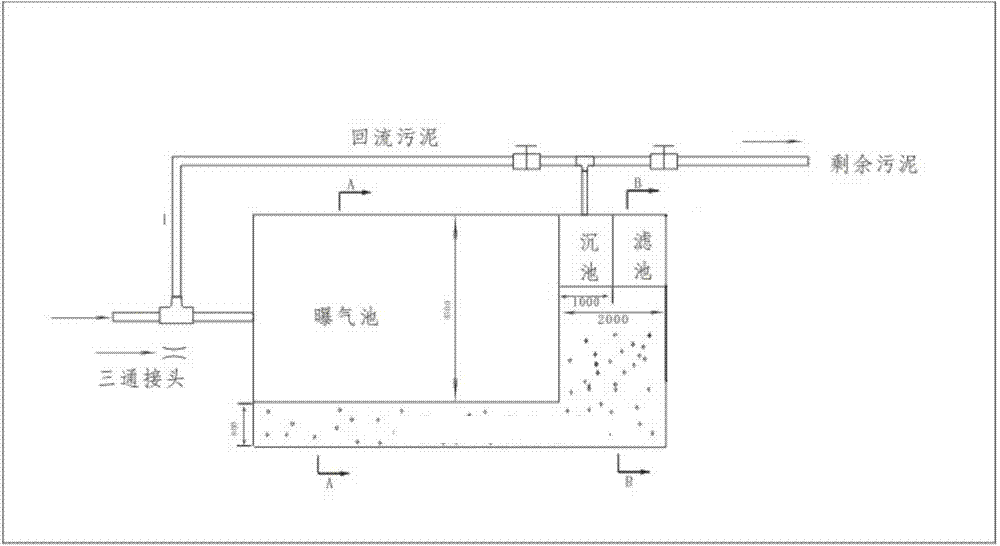

[0067] see figure 1 The biodegradable ethylene oxide waste gas treatment method and system provided by the present invention are based on aeration tanks, sedimentation tanks, and filter tanks to treat ethylene oxide waste gas dissolved in wastewater, including the following operations:

[0068] After dissolving ethylene oxide waste gas in water, the waste water to be treated continuously flows through the aeration tank, sedimentation tank, and filter tank. Among them, the adsorption and metabolism of microbial flora are used in the aeration tank to degrade the ethylene oxide waste gas , settle the microbial flora and settleable debris in the settling tank, and then filter through the filter tank and discharge;

[0069] The aeration tank is pre-set with wastewater containing cultivated and domesticated microbial flora, the microbial flora is suspended in water or forms flocs suspended in water, and the aeration tank is also equipped with a dissolved oxygen control device to mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com