Precision forging technology of tooth forms of duplex straight toothed spur gears

A cylindrical gear and precision forging technology, used in the manufacture of tools, wheels, metal processing equipment, etc., can solve the problems of high material consumption quota, poor mechanical strength of gears, low production efficiency, etc., to reduce material consumption quota and improve meshing strength. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

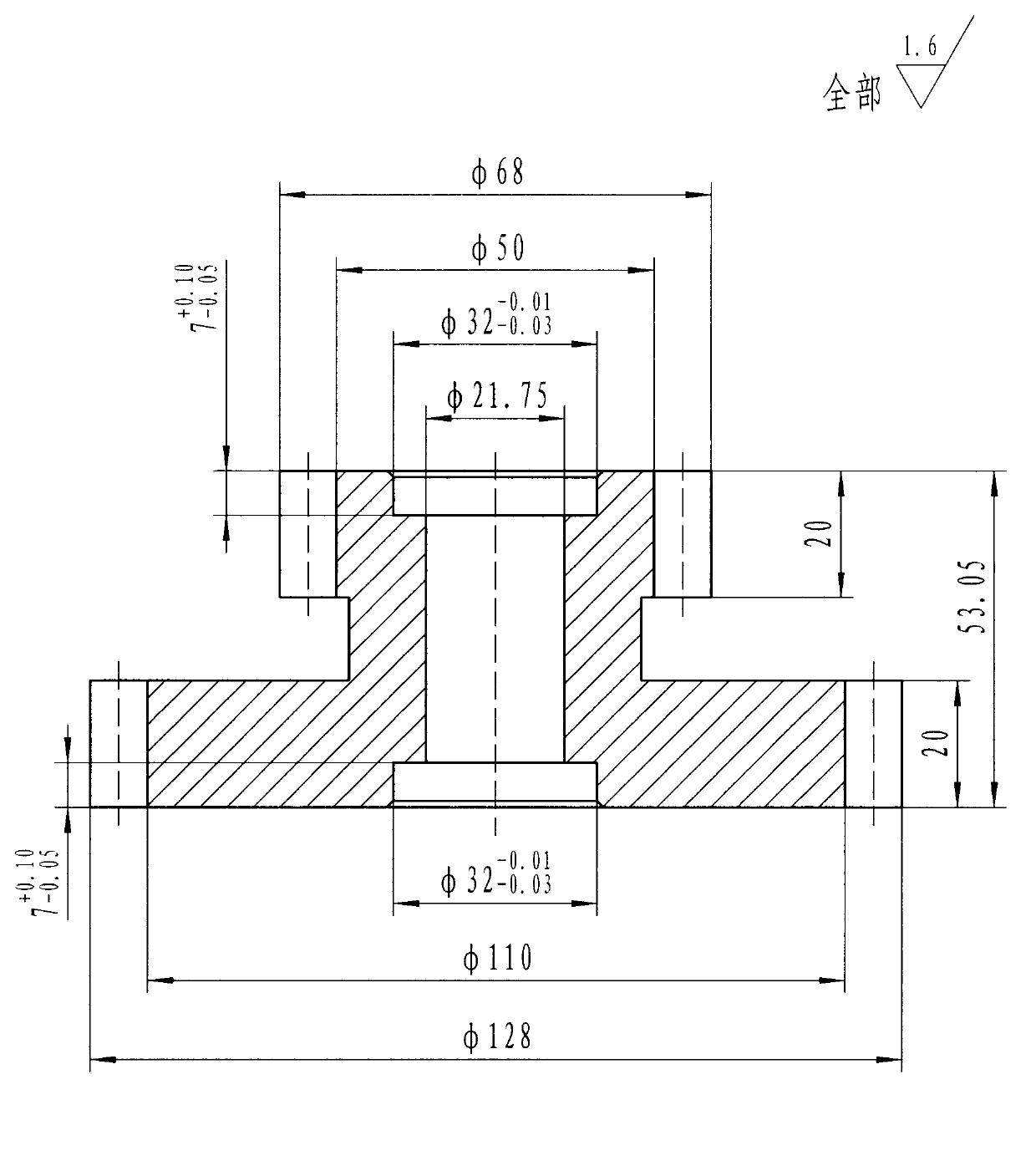

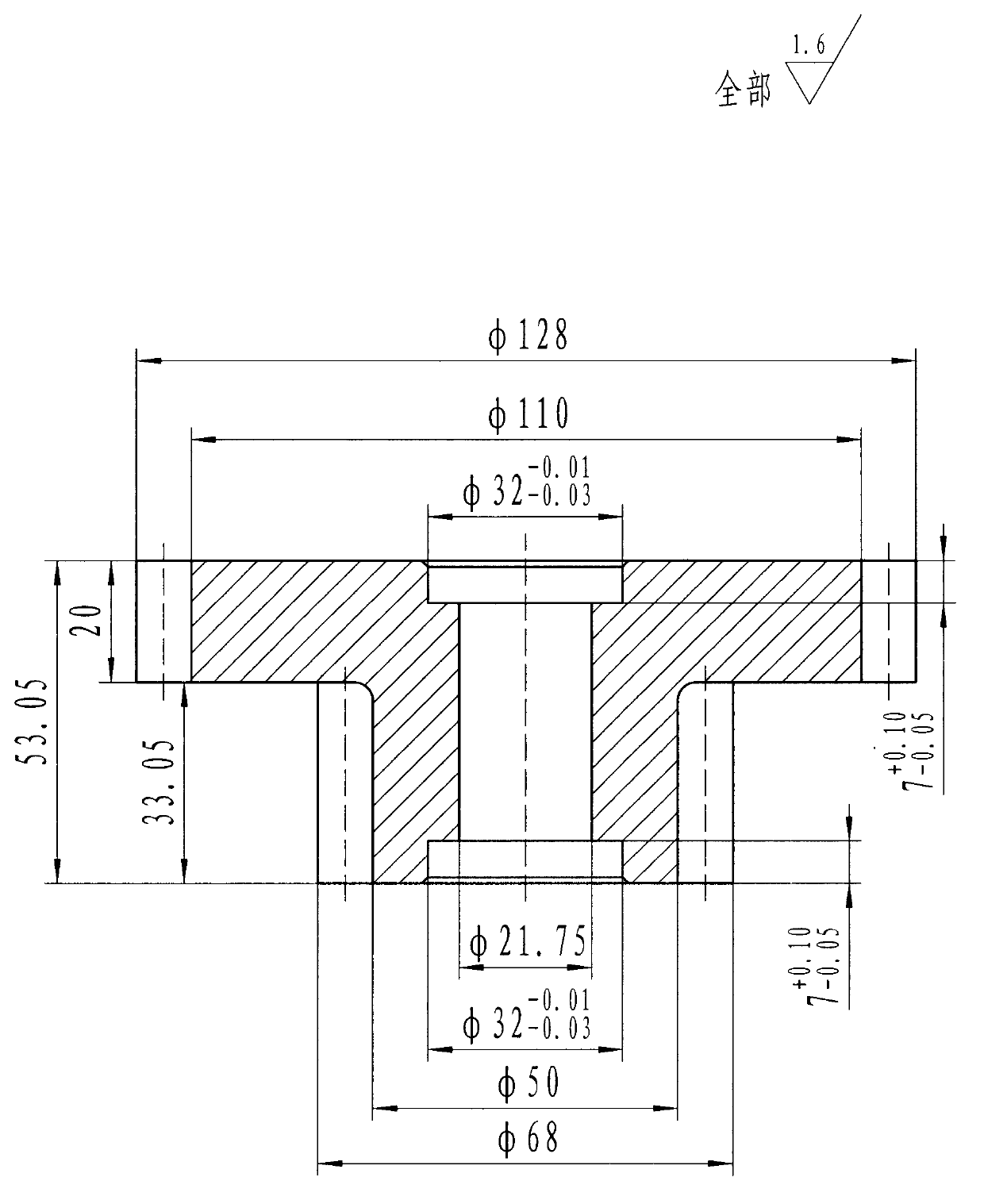

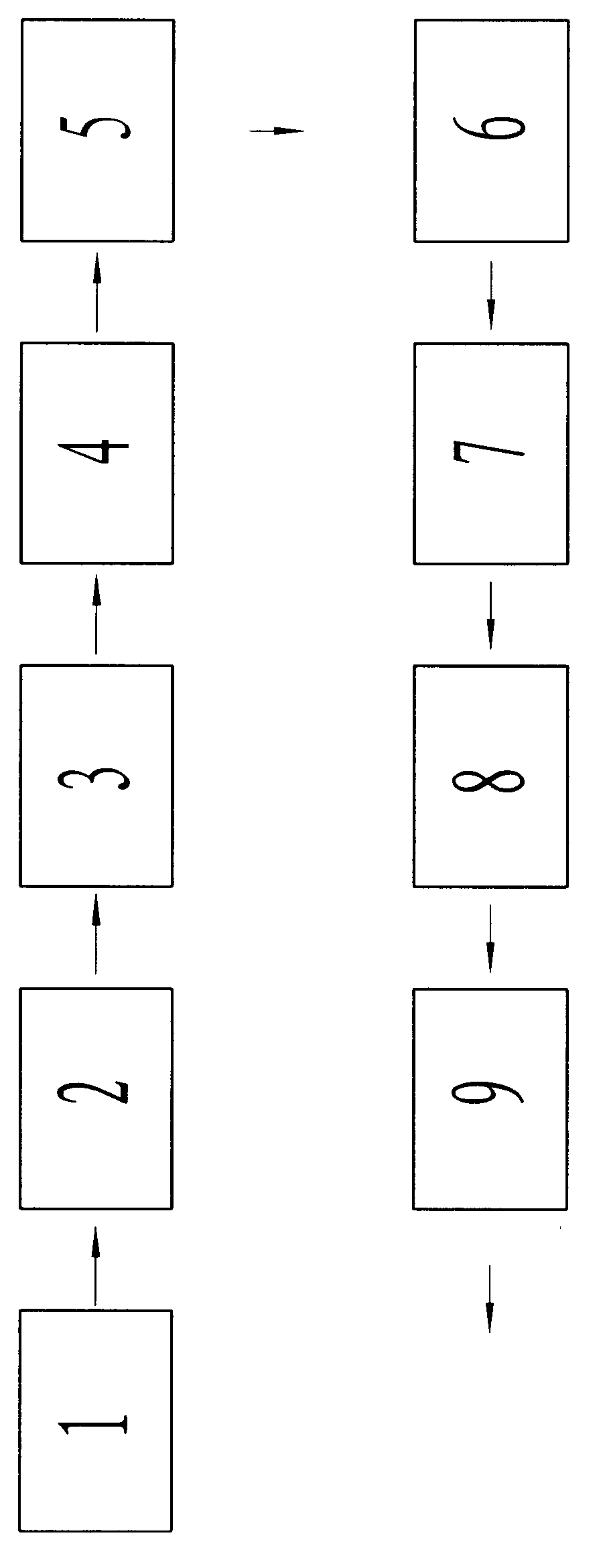

[0029] The "Precision Forging Process of Double-connected Spur Gear Tooth Profile" will be described in detail in conjunction with the drawings. For convenience and accurate description, the part numbers in the drawings are listed in order as follows:

[0030]

[0031]

[0032] The technical points to solve the technical solution for the precision forging process of double spur gears are:

[0033] 1. Follow the attached figure 1 The parts drawing design hot forging drawing, which is the basis for designing the forging die cavity and calculating the blank quality m of forgings.

[0034] 2. Hot forging drawing design, the factors that need to be considered in hot forging drawing design are: ①The first need to consider is the number of heating; ②Determine the initial forging temperature and the final forging temperature after the forging die; ③Determine the cooling of the hot forging according to ① and ② Shrinkage rate, the cooling shrinkage rate of hot forgings is 0.8%-1.2%, the final ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com