Press fitting device and press fitting method for air spring piston

An air spring and press-fitting device technology, which is applied in metal processing, metal processing equipment, hand-held tools, etc., can solve the problems of large footprint of press-fitting equipment, lower production efficiency of press-fitting operations, and complicated equipment, and achieve the goal of pressing The installation method is simple, the pressing equipment is simplified, and the accuracy is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

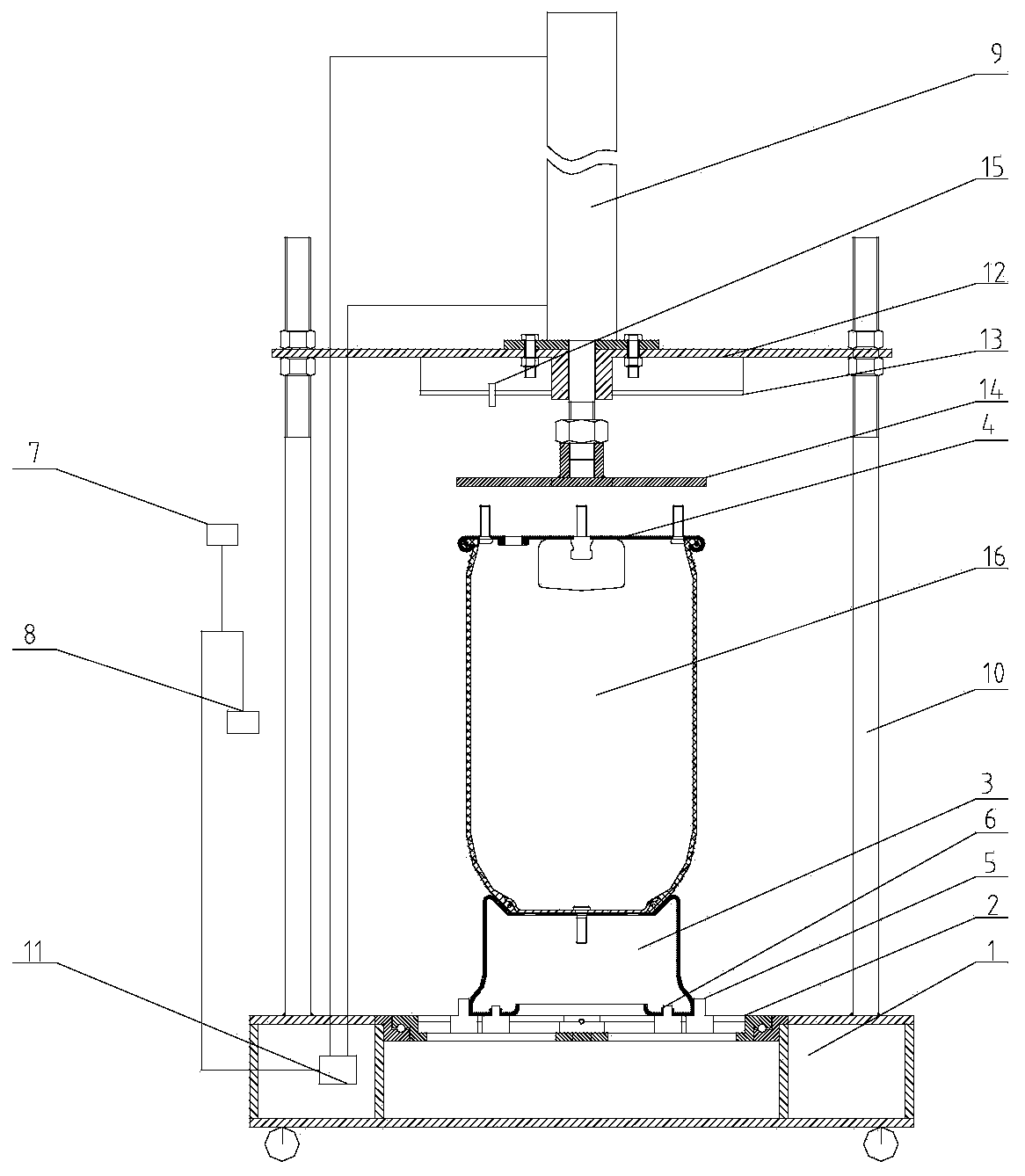

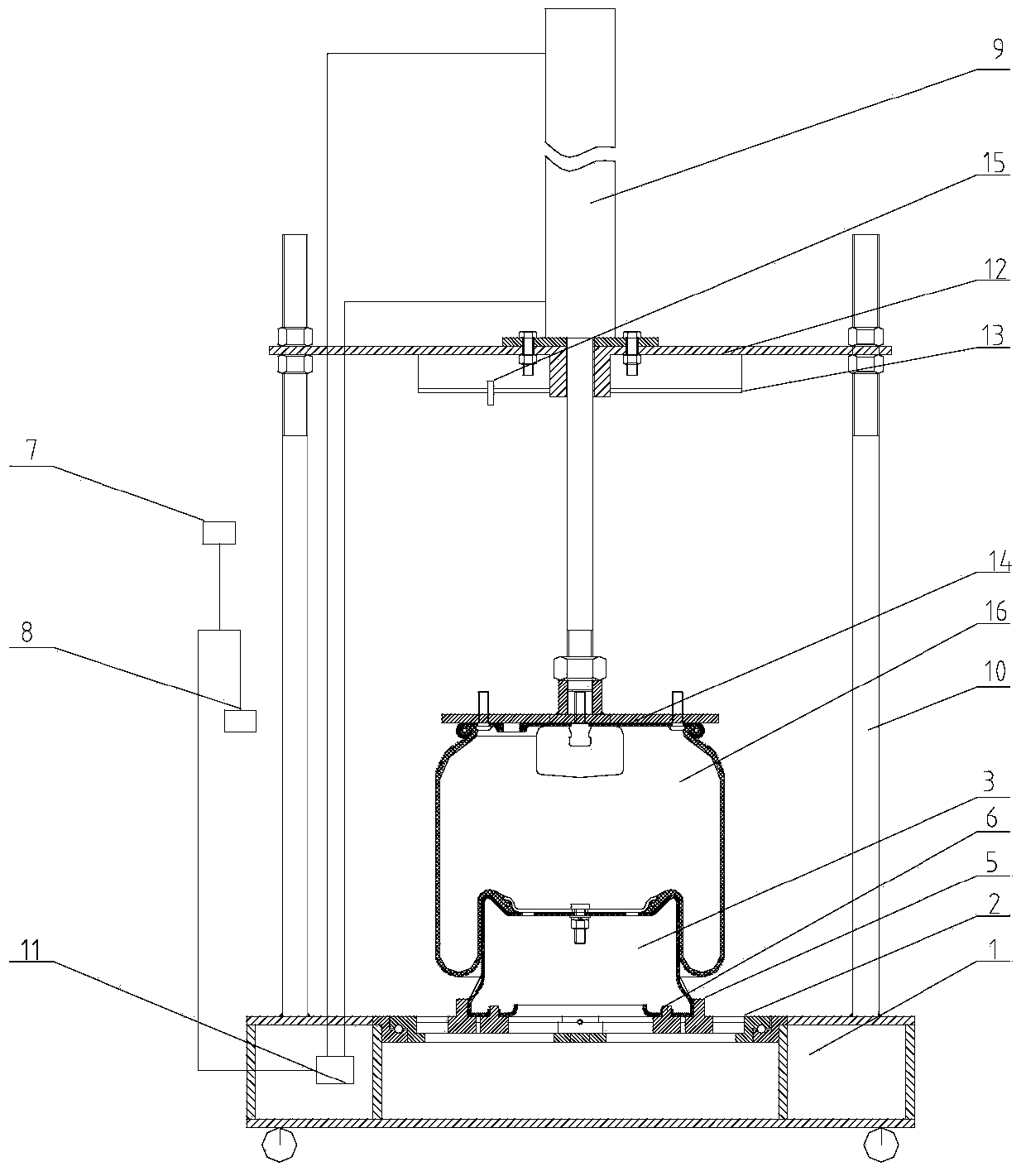

[0025] see figure 1 , an air spring piston pressing device, mainly composed of a machine platform 1, a support bracket, a rotating disk 2, an infrared probe 15, a driving device and a pressure head 14, the machine platform 1 is provided with a machine base, and the rotating disk 2 can be placed on the machine base The upper 360° free rotation, the scale is engraved on the base of the machine, and there are positioning pins to fix the rotating disc 2 after setting any rotation angle, and at the same time, the rotating disc 2 is equipped with a cross chute structure, and the cross chute is equipped with Freely sliding fixed slide block 5 and positioning slide block 6 are provided with positioning screws, which can be positioned after the position of the slide block is set.

[0026] The driving device includes an air source 7, an air gun 8 and an air cylinder 9. The machine table 1 is provided with a cylinder foot valve 11 for controlling the operation of the air cylinder 9. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com