Self-insulation building block molding machine and production method thereof

A technology of self-insulating blocks and insulating blocks, which is applied to ceramic molding machines, ceramic extrusion dies, manufacturing tools, etc., can solve the problems of unfavorable fire prevention, low efficiency, unfavorable promotion, etc., and achieve the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

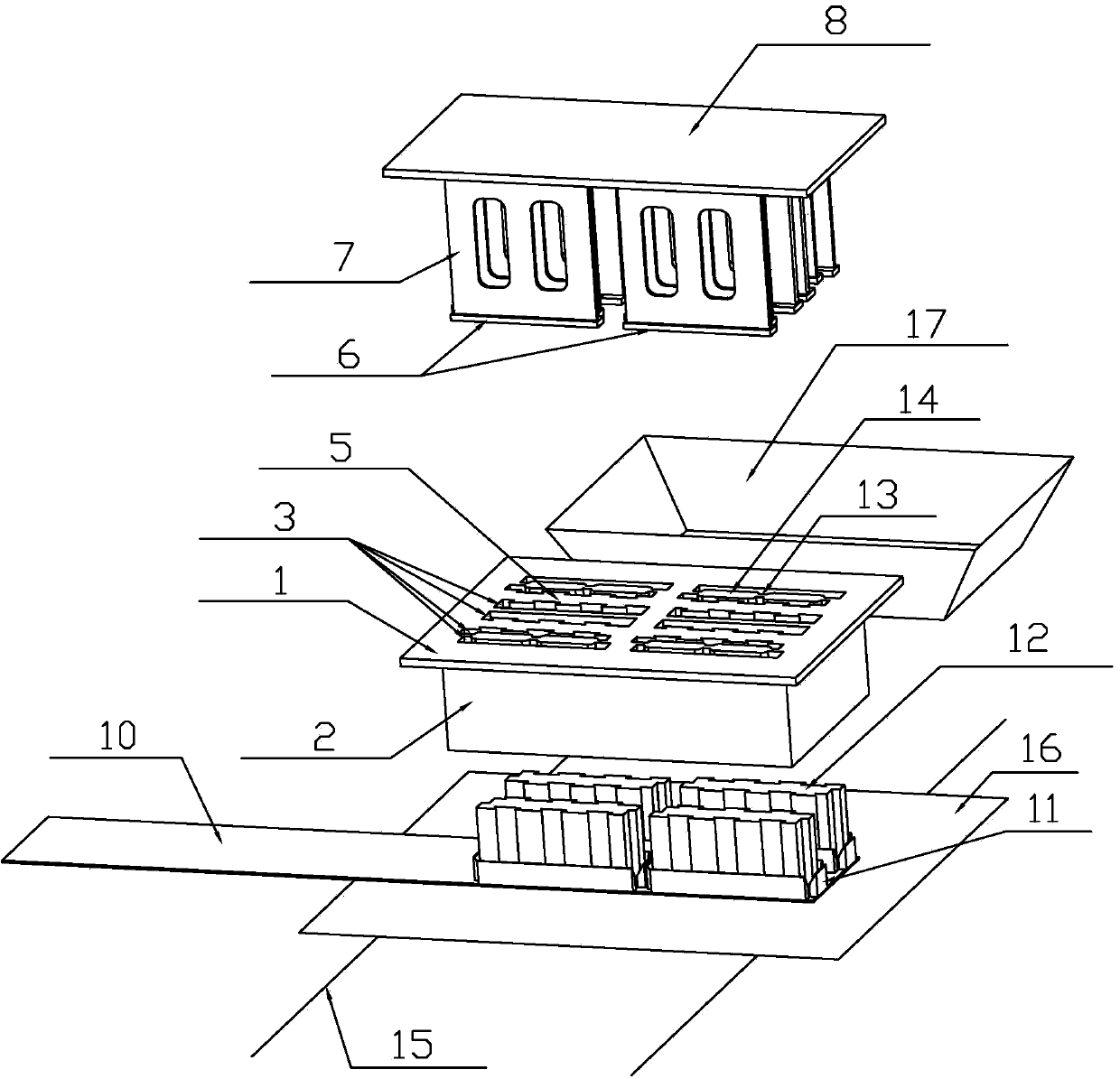

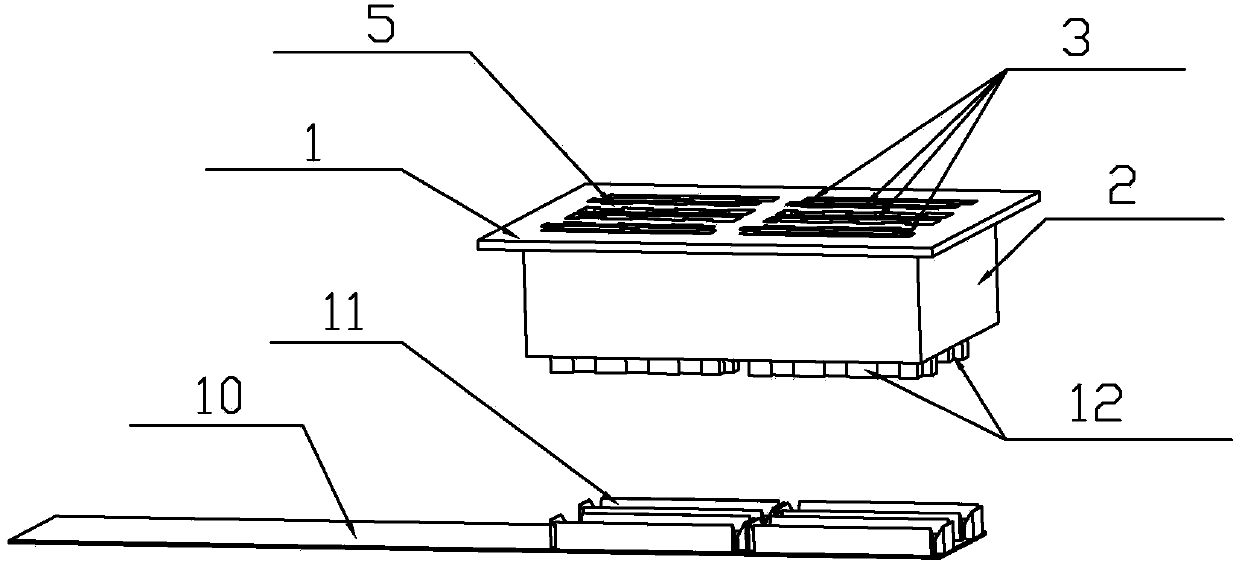

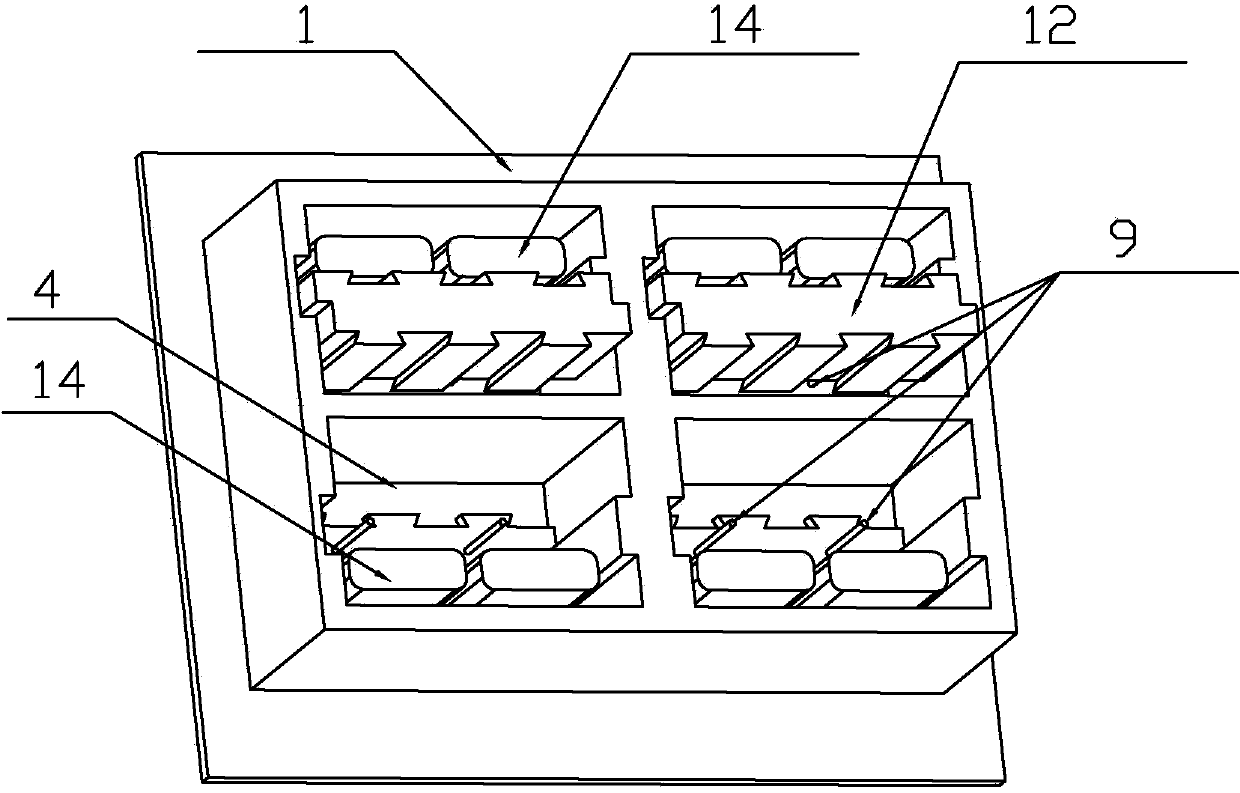

[0027] Implementation mode one: if Figure 1-8 As shown, the self-insulating block molding machine of the present invention includes a material distribution device 17 and an extrusion molding device. There are N groups of cloth extrusion slots 3 on the die top plate 1, and the mold frame 2 is arranged under the lower die top plate 1, and forms a forming space 4 under each group of cloth extrusion slots 3, and each forming space 4 contains Insulation block area, the top plate above the insulation block area is provided with an insulation block protection plate 5, the insulation block protection plate 5 is located between the adjacent cloth extrusion slots 3, and the upper die includes a pressure head 6 corresponding to the shape of the cloth extrusion slot 4 , the above-mentioned indenters 6 are respectively fixed on an upper mold base plate 8 through a connecting plate 7, and the upper mold and the lower mold are respectively equipped with a hydraulic lifting mechanism and a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com