A combined high-speed aircraft carrier with a wind tunnel assisting system and its construction method

A construction method and combined technology, applied in aircraft carriers, ship construction, hull decks, etc., can solve the problems of short service life, environmental pollution, high accident rate, increase speed and power supply load, improve combat preparation time, The effect of reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

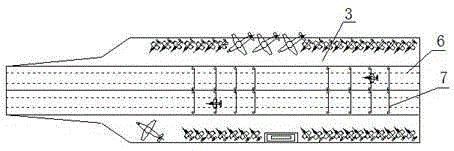

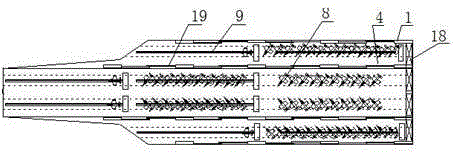

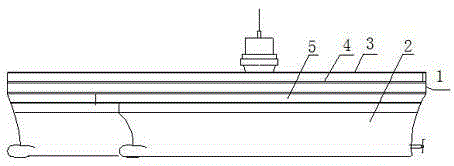

[0049] With reference to the accompanying drawings of the description, the split and combined aircraft carrier with the wind tunnel flying aid system of the present invention will be described in detail below.

[0050] Such as figure 1 figure 2 image 3 As shown, the combined high-speed aircraft carrier with a wind tunnel flight aid system and its construction method of the present invention is to decompose the aircraft carrier into a composite deck module 1 and a navigation power module 2, and the composite deck module 1 and the navigation power module 2 are passed through a dovetail Slot structure connection, in the design of the composite deck module 1, the take-off deck and the landing deck are separated in layers, but the functions of landing and take-off can be taken into account. The shape adopts the upper standard deck shape of the Ford-class aircraft carrier. through runway;

[0051] Such as Figure 8-10 As shown, in the design of the sailing power module 2, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com