Engineering rotor-type unmanned aircraft

An unmanned aerial vehicle and rotor technology, applied in the field of unmanned aerial vehicles, can solve the problems of operation in areas where aerial flight cannot be performed in a complex environment, low maneuverability, low controllability, etc. Operational safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

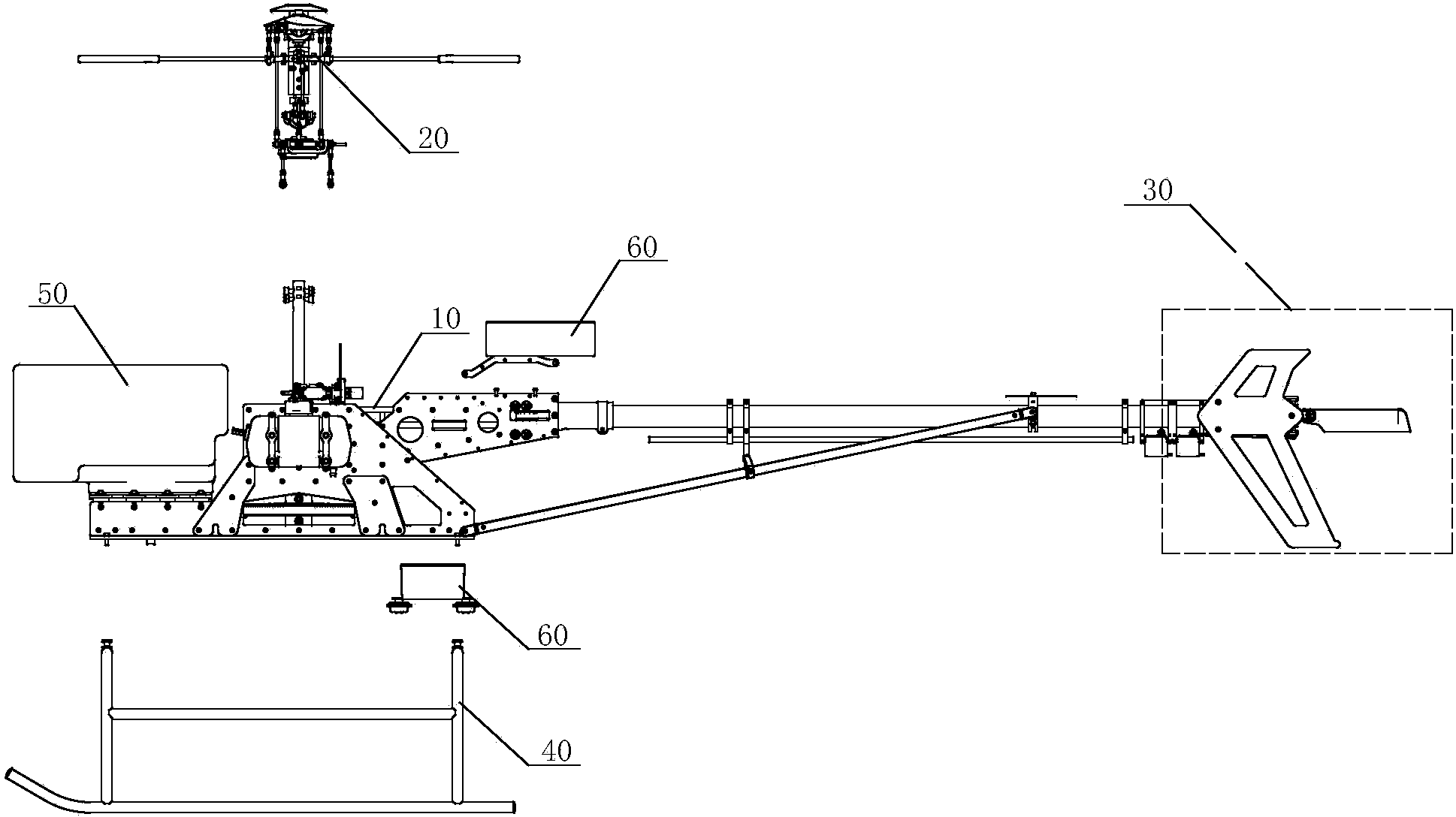

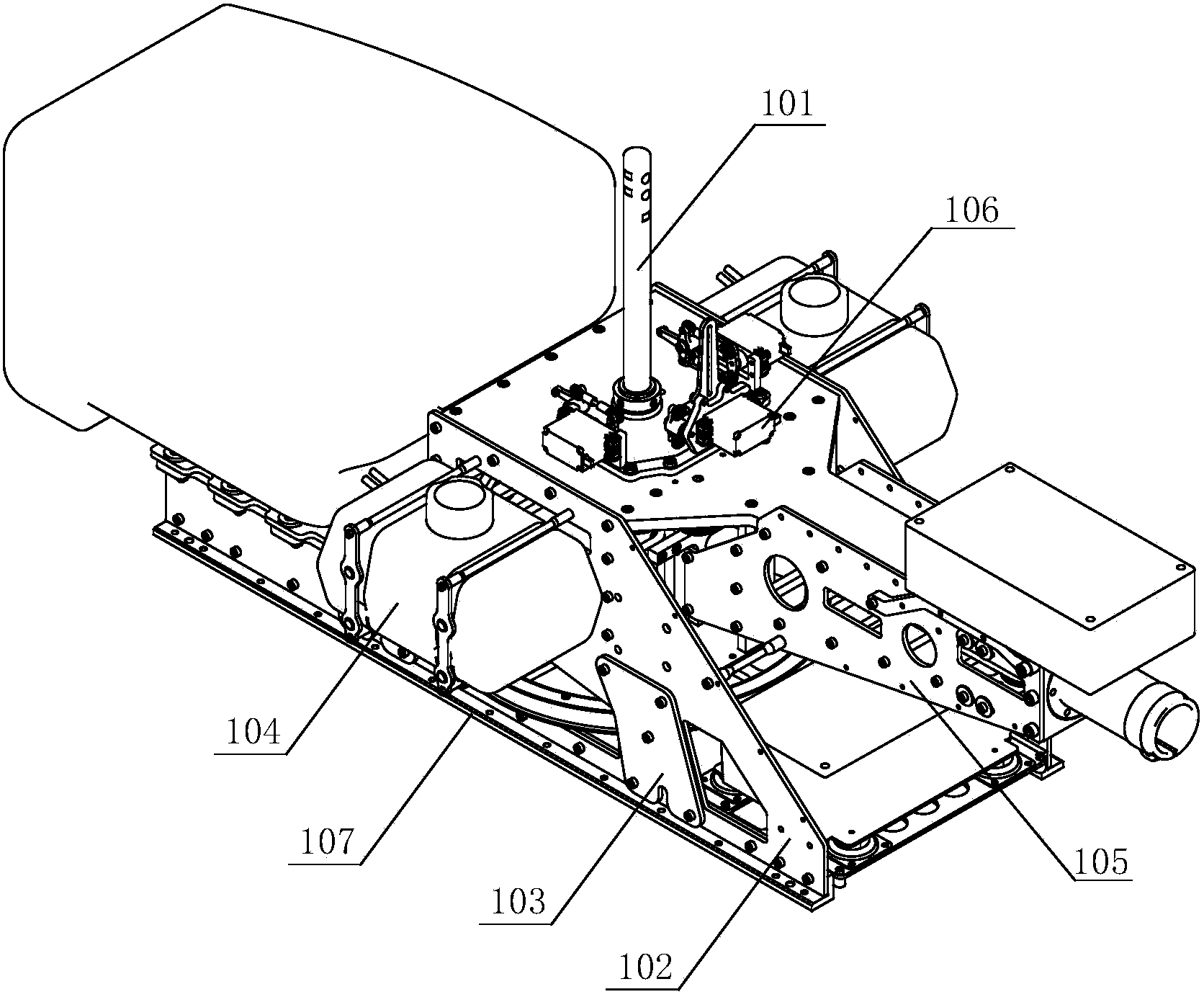

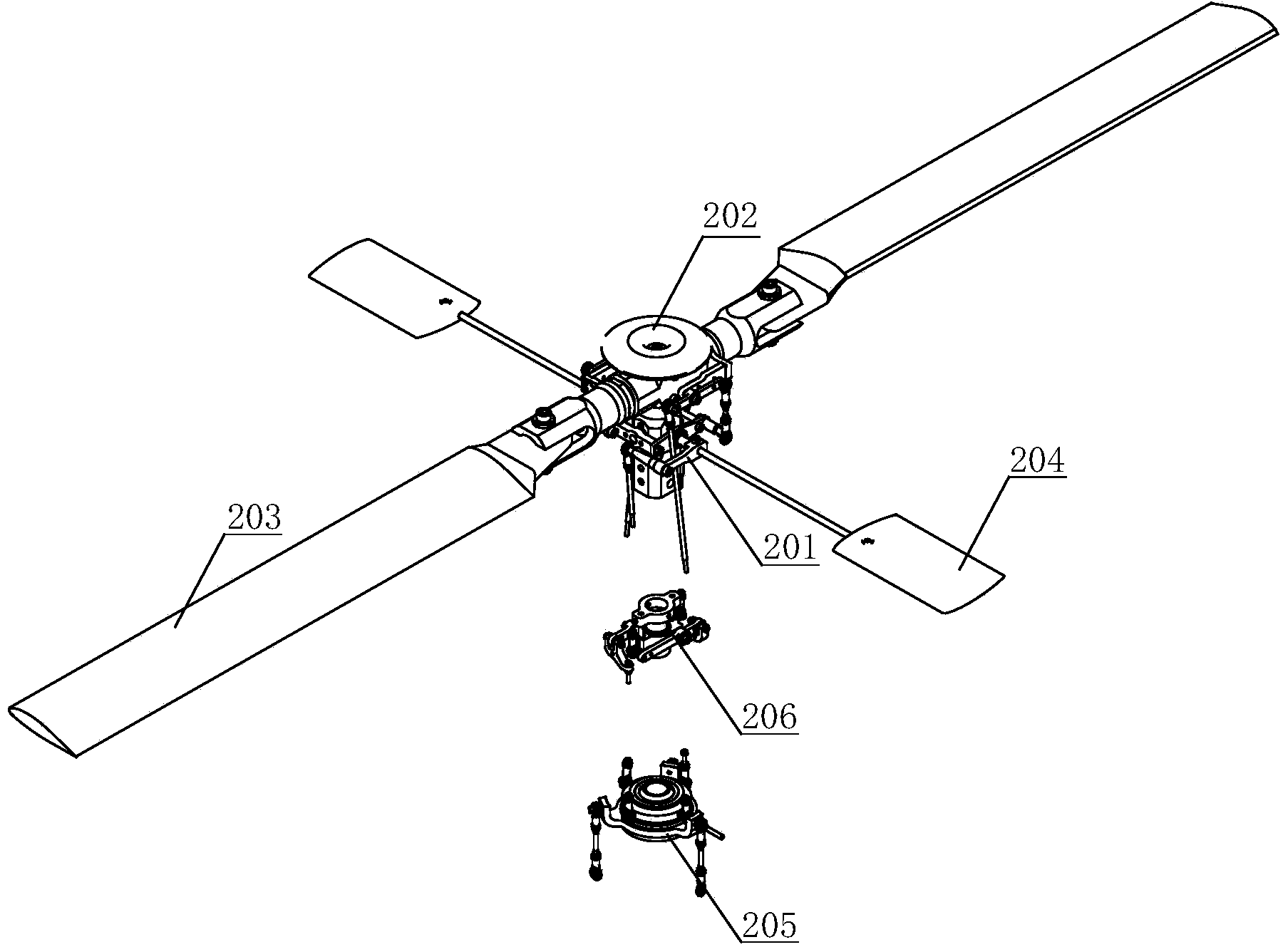

[0022] a kind of like figure 1 , figure 2 Described a kind of engineering type rotor type unmanned aerial vehicle comprises main frame 10, engine assembly 50, rotor 20, tail drive 30, landing gear 40, and described main frame 10 comprises main shaft 101, is relatively arranged on main shaft 101 both sides The side plate 102, the fuel tank 104 fixed on the outside of the side plate 102 with a capacity of 2L, the frame fixing beam 107 arranged at the lower end of the main frame 10 and fixedly connected with the side plate 102, the main shaft 101 is provided with a transmission assembly 106. The side plate 102 is provided with a side plate reinforcing plate 103 . The engine assembly 50 is arranged on the main frame 10 and fixedly connected with the frame fixing beam 107 . The engine assembly 50 is equipped with a fuel tank with a capaci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com