Preparation method of diethyl carbonate and methylethyl carbonate

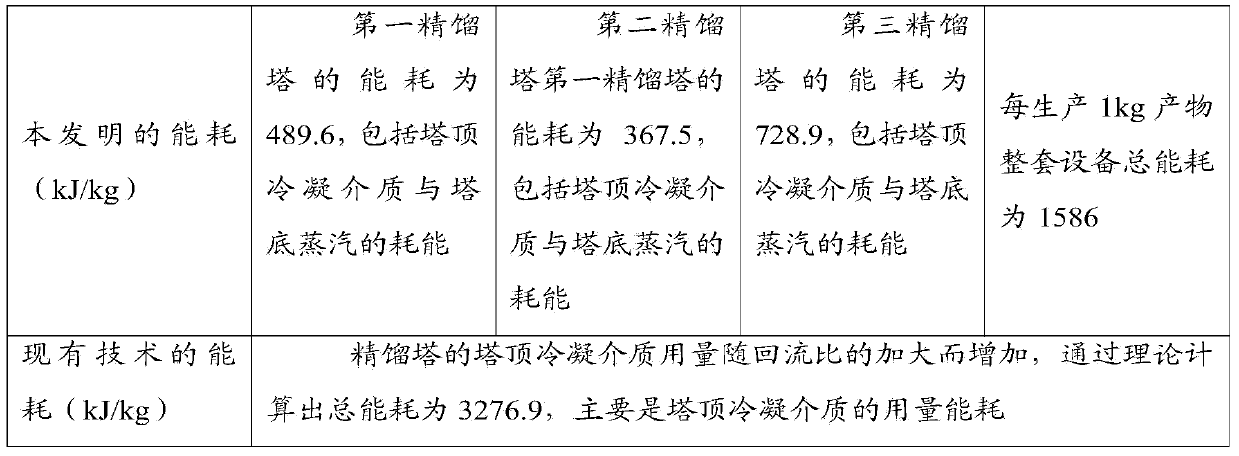

A technology of diethyl carbonate and methyl ethyl carbonate, applied in the field of preparation of diethyl carbonate and methyl ethyl carbonate, can solve problems such as increased energy consumption, and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

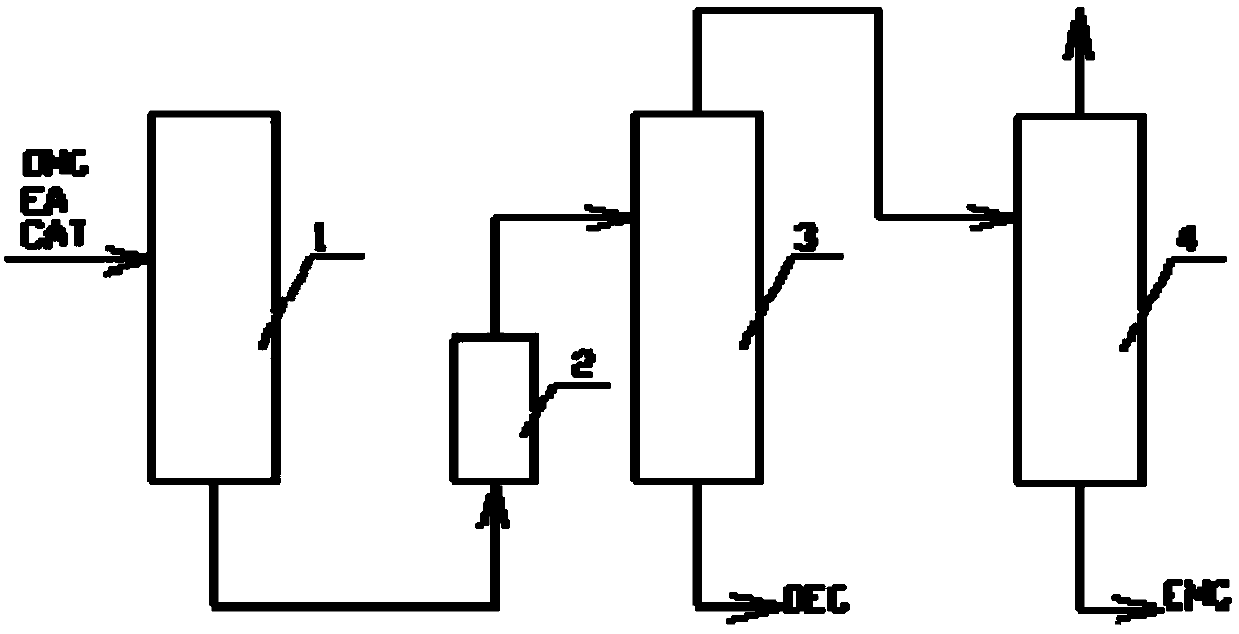

[0034] The raw materials dimethyl carbonate (DMC) and absolute ethanol (EA) are continuously added to the first rectification tower at a mass ratio of 3:1, and the catalyst to raw material mass ratio is 10:100 for reactive rectification. The temperature of the tower kettle is controlled at 80°C;

[0035] Add the material from the bottom of the first rectification tower to the second rectification tower for reactive rectification. The temperature of the bottom of the second rectification tower is controlled at 115°C; the bottom of the second rectification tower gets the product diethyl carbonate Fat(DEC);

[0036] Add the material from the top of the second rectification tower to the third rectification tower for reactive rectification, the temperature of the bottom of the third rectification tower is controlled at 100°C; the bottom of the third rectification tower gets the product ethyl methyl carbonate (EMC).

[0037] Excessive raw material dimethyl carbonate leads to a hig...

Embodiment 2

[0039] The raw materials dimethyl carbonate (DMC) and absolute ethanol (EA) are continuously added to the first rectification tower at a mass ratio of 1:0.5, catalyst to raw material at a mass ratio of 1:200 for reactive rectification. The temperature of the tower bottom is controlled at 100°C, and the temperature of the top of the first rectification tower is controlled at 63°C;

[0040] Add the material from the bottom of the first rectification tower to the second rectification tower for reactive rectification. The temperature of the bottom of the second rectification tower is controlled at 130°C; the bottom of the second rectification tower gets the product diethyl carbonate Fat(DEC);

[0041] Add the material from the top of the second rectification tower to the third rectification tower for reactive rectification, the temperature of the bottom of the third rectification tower is controlled at 115°C; the bottom of the third rectification tower gets the product ethyl methy...

Embodiment 3

[0044] The raw materials dimethyl carbonate (DMC) and absolute ethanol (EA) are continuously added to the first rectification tower at a mass ratio of 1:1, and the mass ratio of catalyst to raw materials is 1:20 for reactive rectification. The temperature of the tower bottom is controlled at 90°C, and the temperature of the top of the first rectification tower is controlled at 65°C;

[0045] Add the material from the bottom of the first rectification tower to the second rectification tower for reactive distillation. The temperature of the bottom of the second rectification tower is controlled at 120°C, and the temperature at the top of the second rectification tower is controlled at 95°C. , the product diethyl carbonate (DEC) is obtained from the tower still of the second rectification tower;

[0046]Add the material from the top of the second rectification tower to the third rectification tower for reactive rectification, the temperature of the bottom of the third rectificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com