Descaling equipment and descaling systems

An equipment and scaling technology, which is applied in the petroleum industry, refined hydrocarbon oil, etc., can solve the problems of incomplete descaling, short anti-scaling time, and inconvenient dosing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

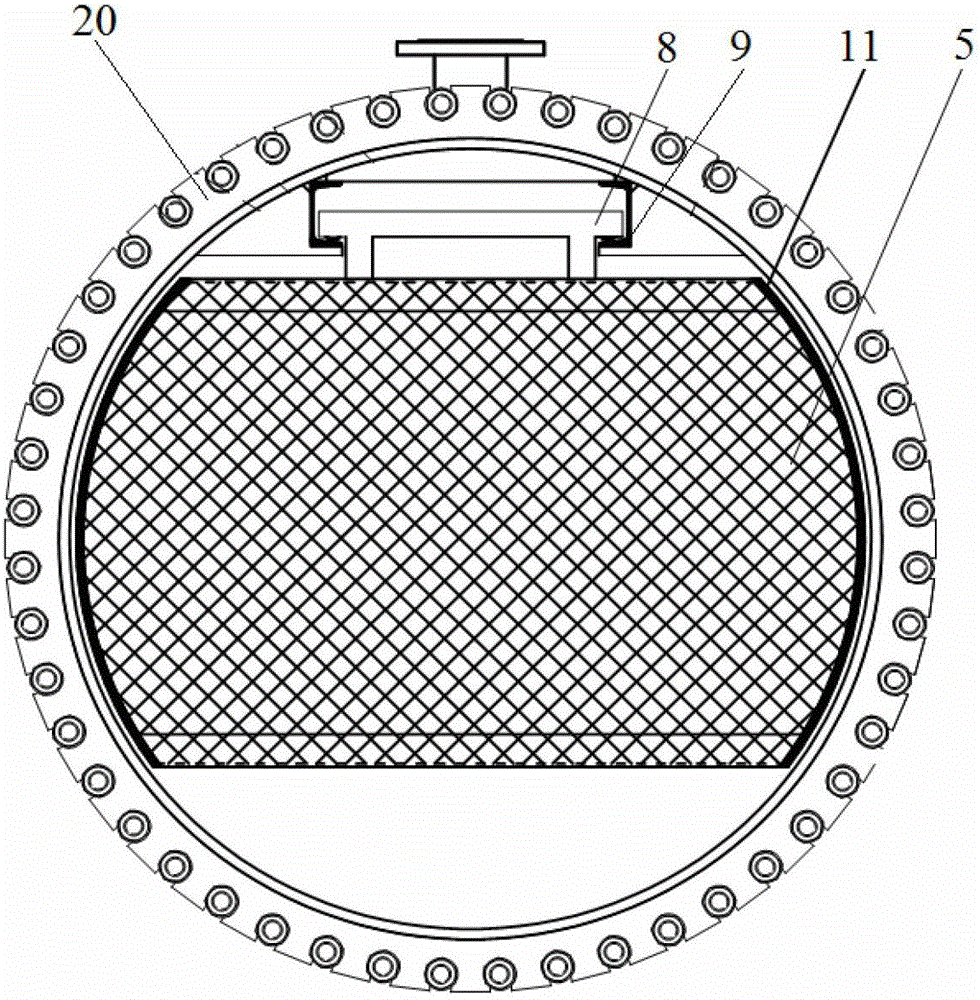

[0063] As a preferred embodiment of the present invention, the diameter of the through hole 6 is 45mm-80mm. The through hole 6 can adopt various shapes and sizes, and the through hole 6 with a diameter of 45 mm to 80 mm can keep the flow rate of the liquid in the descaling unit 2 within a predetermined range and improve the descaling effect.

[0064] The corrugated plate 5 can be made of various materials that do not react chemically with the liquid. Preferably, the corrugated plate 5 is made of glass fiber reinforced plastic or stainless steel. FRP or stainless steel has good corrosion resistance, is not easy to be corroded, and its composition is stable, and will not chemically react with liquid, so it is suitable for making the corrugated plate 5 for descaling.

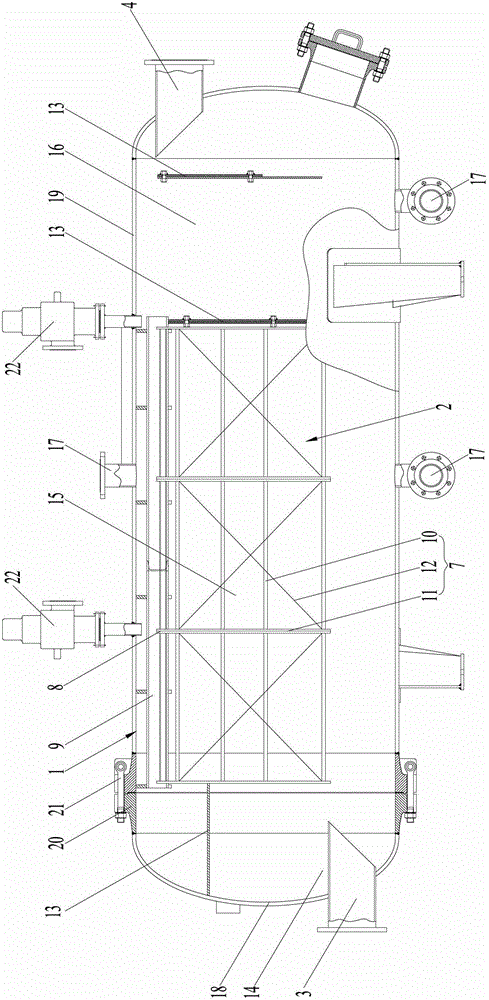

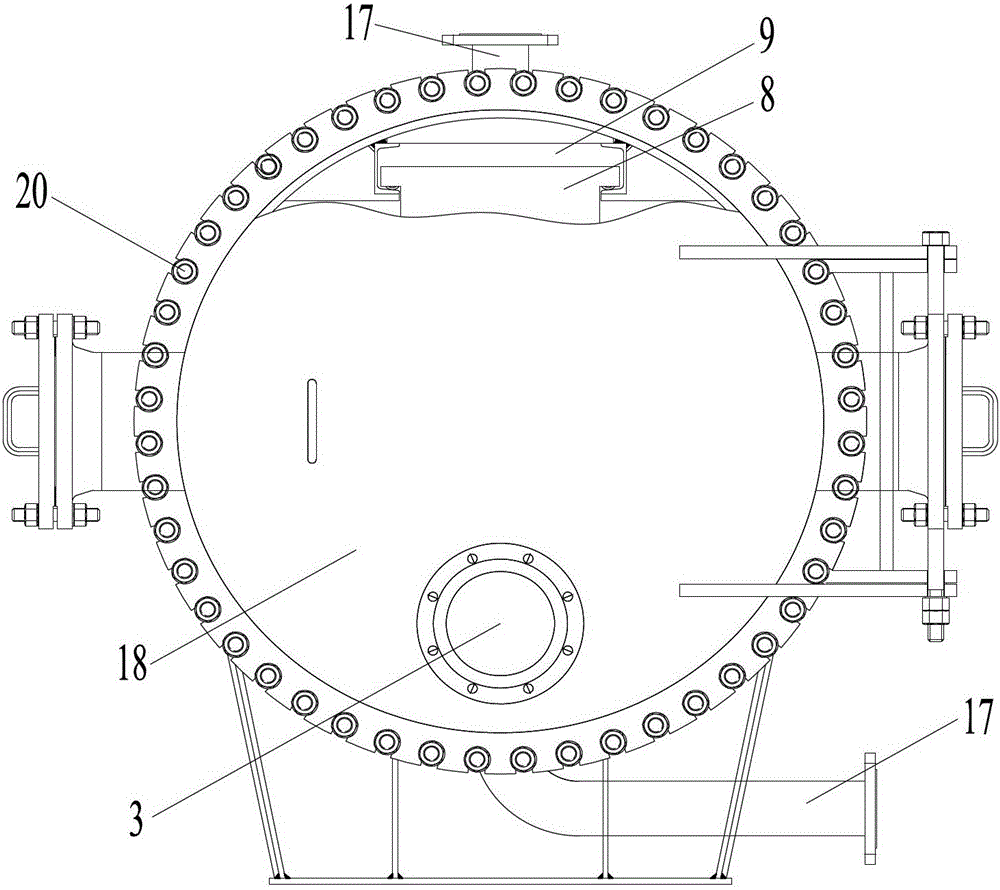

[0065] Such as figure 1 and image 3 As shown, in order to facilitate the installation of the corrugated plates 5, preferably, the fouling unit 2 further includes a frame 7, and the multiple corrugated plates 5 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com