Unfired gangue foaming acoustical board

A technology for sound-absorbing panels and tailings, which is used in sound insulation, noise absorption devices, building components, etc., can solve the hidden dangers of tailings pond safety, threats to people's property and life safety in surrounding areas, etc. The effect of large volume and strong foaming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with embodiment the present invention will be further described:

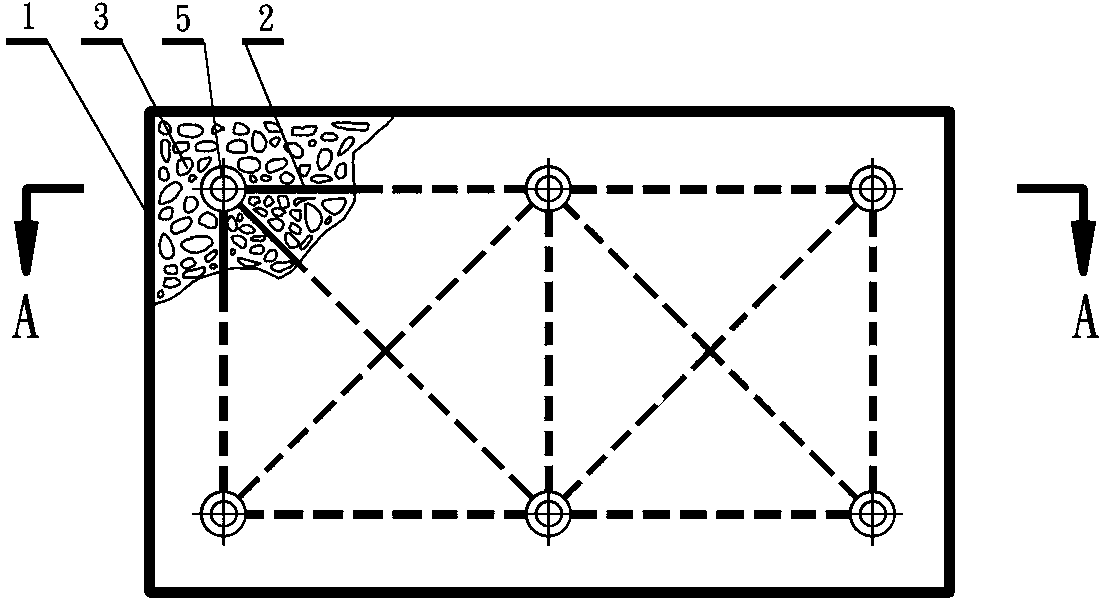

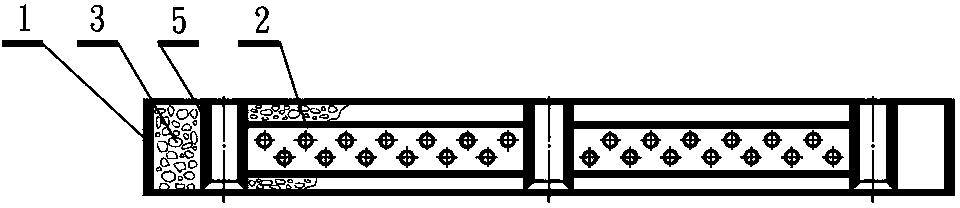

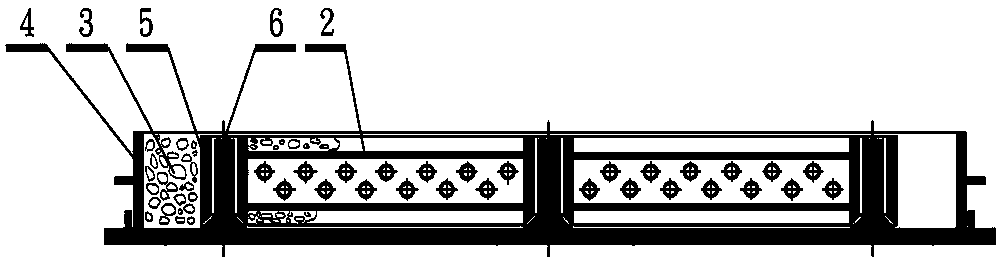

[0044] The non-burning tailings foam sound-absorbing board is a rectangular plate-shaped object 1, which is composed of a built-in frame 2 and a tailings cement foaming agent 3. The built-in frame 2 is designed with 6 short steel pipes 5; the built-in frame 2 is laid flat On the mold 4, after the short steel pipe 5 in the built-in frame 2 is inserted into the column 6, the tailings cement foaming agent 3 is used to cast it on the periphery of the built-in frame 2, and after the built-in frame 2 is completely embedded in the inside of the tailings cement foaming agent 3, It is the semi-finished product of non-burning tailings foamed sound-absorbing board; after 5 days of static curing treatment, the semi-finished product of non-burned tailings foamed sound-absorbing board is taken out of the mold, and it is maintained according to the conventional maintenance method of cement products....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com