Anchoring method of kiln liner of cylindrical rotary thermal equipment

An anchoring method and cylindrical technology, applied in the direction of lining support, can solve the problem of low service life of the kiln lining, and achieve the effect of preventing falling off or damage and enhancing the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

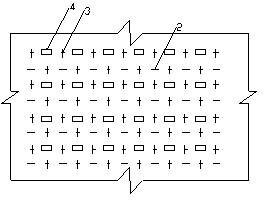

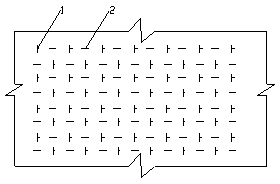

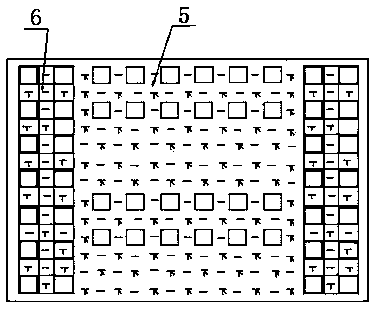

[0026] As shown in the figure, an anchoring method for the kiln lining of a cylindrical rotary heat equipment is to apply anchors to the root of the kiln lining and the upper part of the kiln lining to stably fix each part of the lining at the initial set position. , and the anchor point at the root of the kiln lining is at least 1.5 times that of the upper part of the kiln lining. The anchors include "V"-shaped anchors 1, "Y"-shaped anchors 2, oblique triangle anchors 3, and The refractory blocks 4 are configured with anchors in different combinations according to the temperature range of different regions of the kiln lining, so as to maintain the effectiveness of the entire kiln lining anchors for kiln lining anchoring.

[0027] The kiln lining selects different combinations of anchors according to the furnace lining temperature. When the furnace lining temperature is ≤300°C, the anchors are made of ordinary carbon steel bars to make "V"-shaped anchors 1 and "Y"-shaped anc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com