A preparation method of strain sensor based on carbon nanotube three-dimensional network film

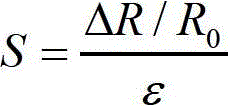

A strain sensor and carbon nanotube technology, applied in the field of material science, can solve the problems affecting the construction of sensing network, the increase of resin matrix viscosity, and the mechanical properties of composite materials, etc., and achieve excellent strain sensing accuracy and linear repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

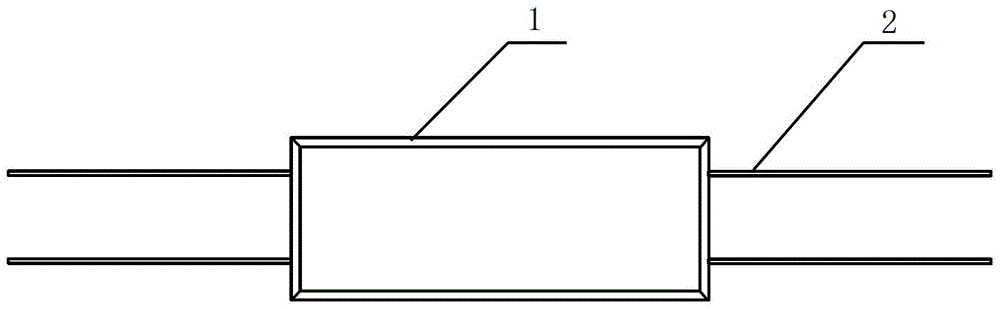

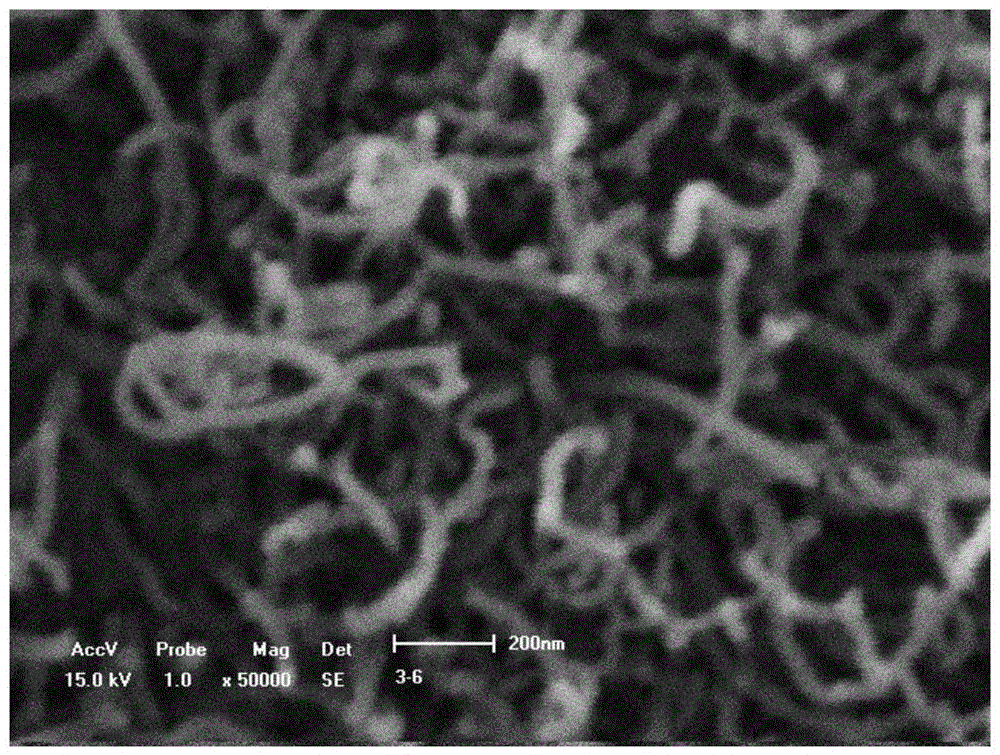

[0020] refer to figure 1 , figure 2 , a method for preparing a strain sensor based on a carbon nanotube three-dimensional network film, which is achieved through the following steps:

[0021] a. A mixture of carbon nanotubes and a surface dispersant is used to prepare a monodisperse aqueous solution of carbon nanotubes by mechanical fusion, wherein the carbon nanotubes are multi-walled carbon nanotubes, the surfactant is TX-100, and the concentration of the aqueous solution of the carbon nanotubes Controlled at 0.1wt%, surfactant: carbon nanotube mass ratio = 5:1, mechanical fusion method mainly includes body grinding, magnetic stirring, ultrasonic dispersion, high-speed centrifugation.

[0022] b. Pour the monodisperse aqueous solution of carbon nanotubes into the upper container of the vacuum suction filter device and filter it on the filter membrane to form a membrane. The filter membrane is selected from 0.22PTFE membrane, and the vacuum degree is controlled to be 60kpa....

Embodiment 2

[0030] refer to figure 1 , figure 2 , a method for preparing a strain sensor based on a carbon nanotube three-dimensional network film, which is achieved through the following steps:

[0031] a. A mixture of carbon nanotubes and a surface dispersant is used to prepare a monodisperse aqueous solution of carbon nanotubes by mechanical fusion, wherein the carbon nanotubes are selected from multi-walled carbon nanotubes, single-walled carbon nanotubes, and functionalized carbon nanotubes. TX-100, SDS, SDBS are selected as the agent, the concentration of the aqueous solution of carbon nanotubes is controlled at 0.01wt%, the surfactant: carbon nanotubes (mass ratio) = 20:1, and the mechanical fusion method mainly includes mortar grinding, magnetic stirring, Ultrasonic dispersion, high-speed centrifugation.

[0032] b. Pour the monodisperse aqueous solution of carbon nanotubes into the upper container of the vacuum suction filter device and filter on the filter membrane to form a ...

Embodiment 3

[0037] refer to figure 1 , figure 2 , a method for preparing a strain sensor based on a carbon nanotube three-dimensional network film, which is achieved through the following steps:

[0038] a. A mixture of carbon nanotubes and a surface dispersant is used to prepare a monodisperse aqueous solution of carbon nanotubes by mechanical fusion, wherein the carbon nanotubes are selected from multi-walled carbon nanotubes, single-walled carbon nanotubes, and functionalized carbon nanotubes. TX-100, SDS, SDBS are selected as the agent, the concentration of the aqueous solution of carbon nanotubes is controlled at 2.5wt%, the surfactant: carbon nanotubes (mass ratio) = 5:1, and the mechanical fusion method mainly includes mortar grinding, magnetic stirring, Ultrasonic dispersion, high-speed centrifugation.

[0039] b. Pour the monodisperse aqueous solution of carbon nanotubes into the upper container of the vacuum suction filtration device and filter on the filter membrane to form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com