Method used for detecting welding quality of welding carried out in intermediate layer connection manner

A connection method and welding quality technology, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, etc., can solve a large number of problems, and achieve the effect of improving detection efficiency, simplifying detection operation process, and reducing detection time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

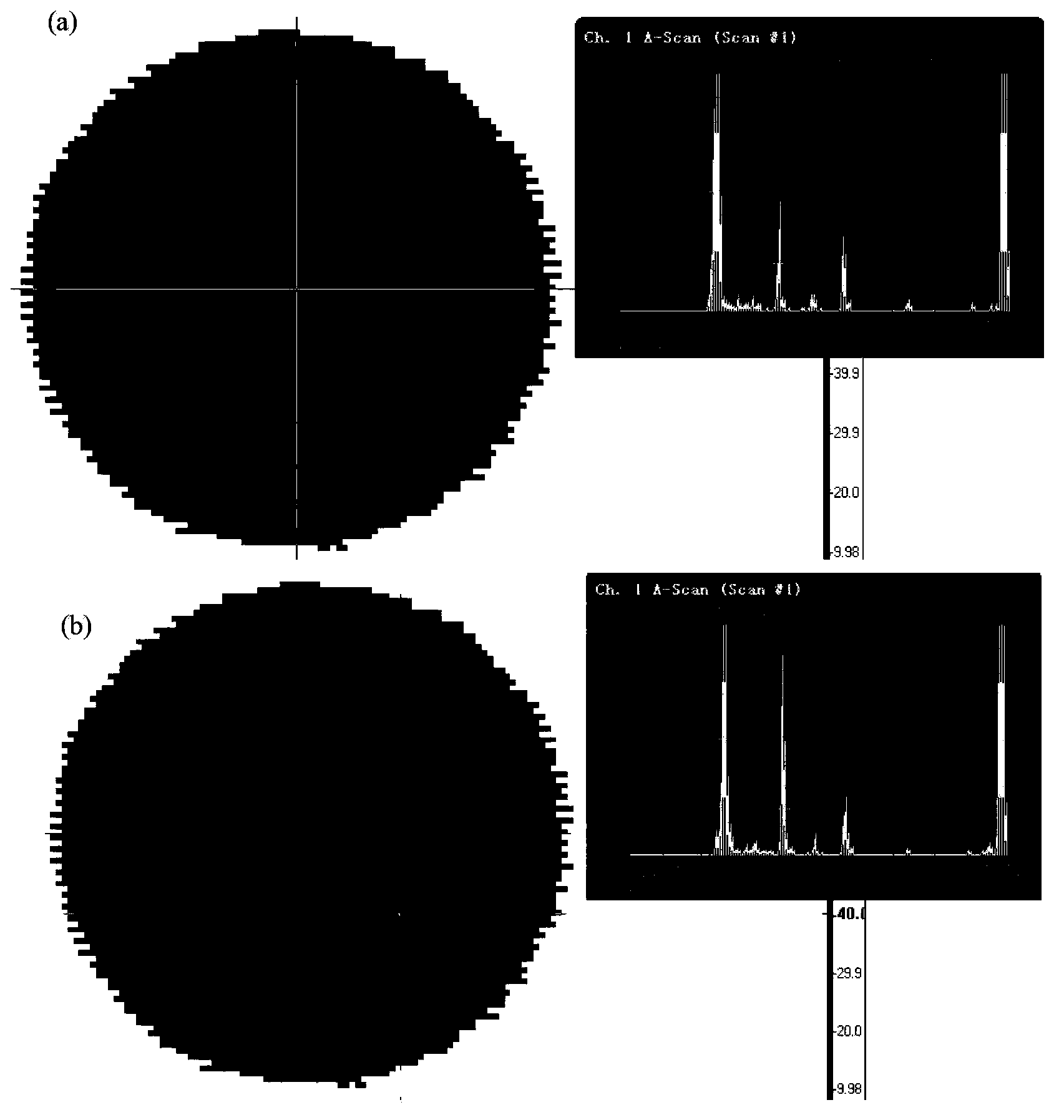

[0024] Clean Al-Cu indium welding comparison test block ( figure 1 a, b) The surface is oily, so that the roughness of the detection surface is ≤6.4μm; then select the water immersion focusing probe, and the frequency of the probe is 10MHz. In A-scan mode, adjust the incident angle of the probe so that the probe is incident vertically on the water layer. Keep the sensitivity unchanged, move along different axes on the detection surface, find the complete welding area with the lowest echo amplitude, adjust the gain value so that the echo height of the welding interface is 50% of the full screen; then the gain value at this time is the scan Check the sensitivity. Put the electronic gate on the welding interface wave, and set the height of the gate to 20% of the full screen. Determine the scanning area, use ultrasonic longitudinal wave pulse reflection to scan, and form an ultrasonic C-scan image. It can be seen that the echo amplitude in the welded area is 50%. figure 2 a, ...

Embodiment 2

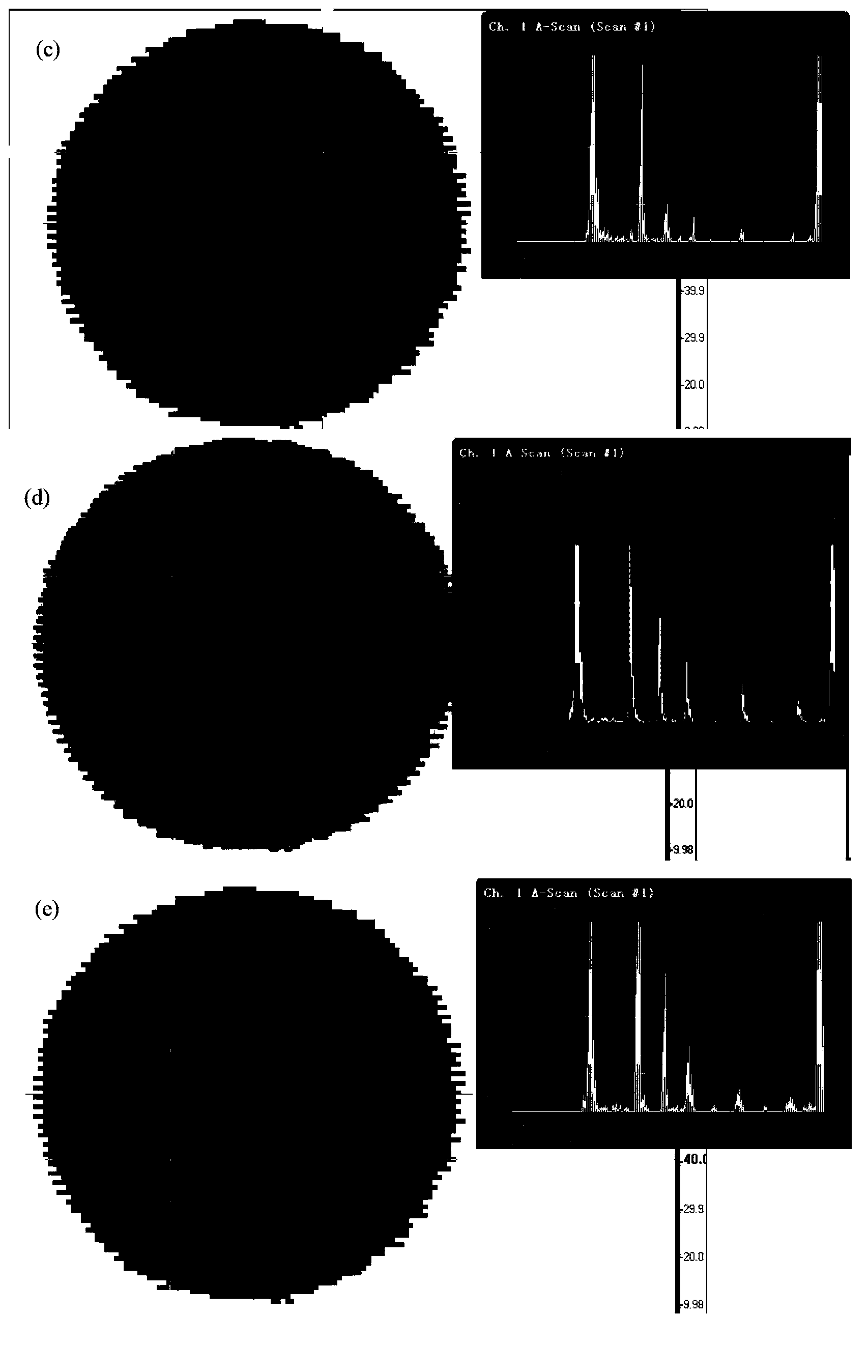

[0027] For the actual ITO ceramic plate and oxygen-free copper plate indium welding welding workpiece (such as image 3 ) detection. Clean the oil on the surface of the workpiece, and then select a water immersion focusing probe with a frequency of 25MHz. In A-scan mode, adjust the incident angle of the probe so that the probe is incident vertically on the water layer. Keep the sensitivity unchanged, move along different axes on the detection surface, find the complete welding area with the lowest echo amplitude, adjust the gain value so that the echo height of the welding interface is 50% of the full screen; then the gain value at this time is the scan Check the sensitivity. Put the electronic gate on the welding interface wave, and set the height of the gate to 30% of the full screen. Determine the scanning area, use ultrasonic longitudinal wave continuous reflection to scan, and form an ultrasonic C-scan image. Ultrasonic images from the Cu-In interface ( Figure 4 ) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com