A method for three-dimensionally judging the fineness of paste printing patterns

A fine and paste technology, applied in the field of fabric printing, to achieve the effects of accurate results, simple and convenient methods, and reliable judgment basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for three-dimensionally judging the fineness of paste printed patterns, comprising the following steps:

[0025] (1) According to the printing paste prescription: 1% K-type Argosol Red P-4B, 5% urea, 1% resist salt S, 1% sodium bicarbonate, 70% original paste. Adjust the viscosity of the color paste to 10000±1000mPa·s (25±1°C, No. 4 rotor, 30r / min, measured by a rotational viscometer).

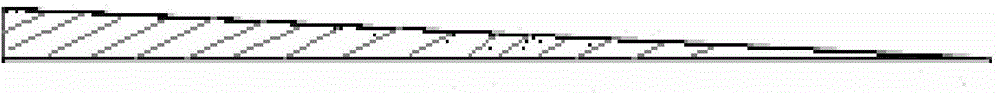

[0026] On a flat screen of 180 mesh, the diameter of the magnetic rod is 8mm, the speed of the vehicle is 6m / min, and the magnetic force is 3 # Cotton fabrics were printed with reactive dyes under certain printing conditions. Print a right-angled wedge-shaped pattern with a length of 100mm and a height of 2mm on the fabric.

[0027] (2) After drying the printed wedge-shaped pattern, measure the actual length and height of the wedge-shaped pattern obtained on the fabric;

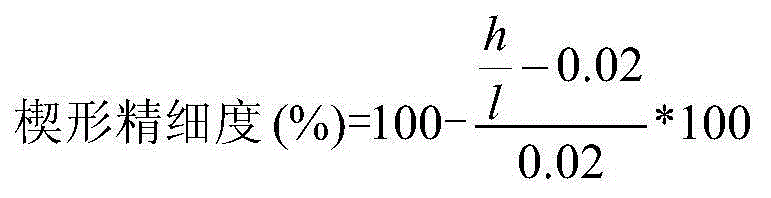

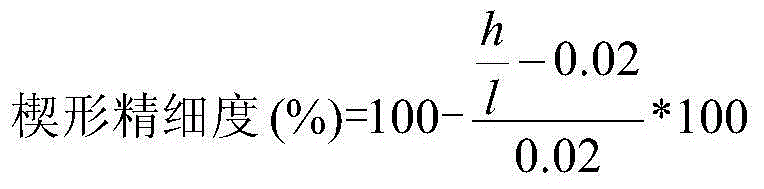

[0028] (3) Calculate the fineness of the wedge shape to judge the fineness of the printed pattern.

[0...

Embodiment 2

[0036] A method for three-dimensionally judging the fineness of paste printed patterns, comprising the following steps:

[0037] (1) According to the printing color paste prescription: 1% K-type Argosol Red P-4B, 5% urea, 1% resist salt S, 1% sodium bicarbonate, 70% original paste, prepare the printing color paste.

[0038] On a flat screen of 180 mesh, the diameter of the magnetic rod is 8mm, the speed of the vehicle is 6m / min, and the magnetic force is 3 # Cotton fabrics were printed with reactive dyes under certain printing conditions. Print a right-angled wedge-shaped pattern with a length of 100mm and a height of 2mm on the fabric.

[0039] (2) After drying the printed wedge-shaped pattern, measure the actual length and height of the wedge-shaped pattern obtained on the fabric;

[0040] (3) Calculate the fineness of the wedge shape to judge the fineness of the printed pattern.

[0041]

[0042] In the formula: l is the actual length of the wedge-shaped pattern on th...

Embodiment 3

[0048] A method for three-dimensionally judging the fineness of paste printed patterns, comprising the following steps:

[0049] (1) Cotton fabric reactive dye printing paste prescription: 1% KN type Argosol black B 133%, 5% urea, 1% resist salt S, 1% sodium bicarbonate, 70% raw paste (sodium alginate original Paste mass fraction is 3%).

[0050] Prescription of disperse dye printing paste for polyester fabric: 1% Yatelong Black SW-FG, 1% urea, 0.1% tartaric acid, 70% raw paste (mass fraction of sodium alginate raw paste is 3%).

[0051] Prescription of disperse / reactive homogeneous printing color paste for polyester-cotton fabric: 1% Artron Black SW-FG, 1% KN Argosol Black B133%, 5% Urea, 1% Resist Salt S, 1% Sodium Bicarbonate , 70% raw paste (mass fraction of sodium alginate raw paste is 3%).

[0052] On a flat screen of 180 mesh, the diameter of the magnetic rod is 8mm, the speed of the vehicle is 6m / min, and the magnetic force is 3 # Printing under the printing conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com