Electrowetting display unit and method for manufacturing thereof

A technology of electrowetting display and manufacturing method, which is applied in chemical instruments and methods, optical components, photolithography process exposure devices, etc., can solve the problems of small differences in hydrophilic and hydrophobic properties, and the inability to further reduce the thickness of electrowetting displays, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

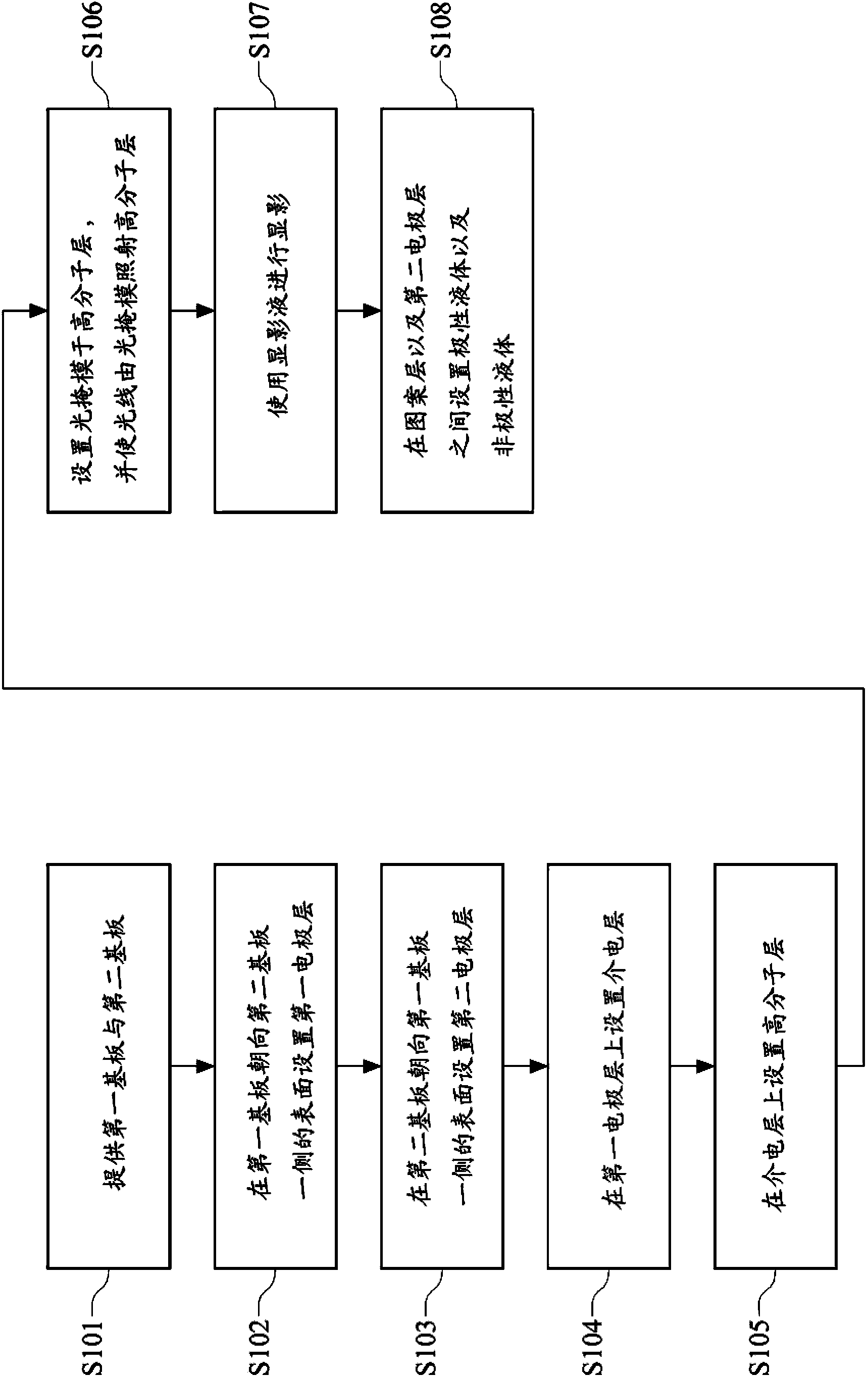

Method used

Image

Examples

Embodiment 1

[0045] First, put 100g of isopropyl alcohol (Isopropyl Alcohol, IPA) into a round bottom bottle, and then put 1.0g of (3-aminopropyl) triethoxysilane ((3-aminopropyl) triethoxysilane) (Aldrich) into Stir into a round bottom bottle. Next, take out 5 g of the above mixed solution and put it into another round bottom bottle, and then add 0.2 g of vinyl-terminated polydimethylsiloxane (Mw=6,000) (product code: Gelest DMS- V21) and 7 mg of platinum (II) acetylacetonate (platinum (II) acetylacetonate) (Aldrich). Wherein, the vinyl-terminated polydimethylsiloxane is an organosiloxane with a Si-H bond, and the photocrosslinkable group is a vinyl group with a carbon-carbon double bond. The above mixed solution was stirred at room temperature for 1 hour, and then the mixed solution was coated on the substrate by spin coating, wherein the rotation rate of the spin coating was 3000 rpm (rotation per minute, rpm) and the coating time was 20 seconds . Next, set a photomask above the subs...

Embodiment 2

[0048] First, put 100g of isopropyl alcohol (Isopropyl Alcohol, IPA) into a round bottom bottle, and then put 1.0g of (3-aminopropyl) triethoxysilane ((3-aminopropyl) triethoxysilane) (Aldrich) into Stir into a round bottom bottle. Next, take out 5 g of the above mixed solution and put it into another round bottom bottle, then add 0.2 g of vinyl-terminated polydimethylsiloxane (vinyl-terminated polydimethylsiloxane) (Mw=17,200) (product number: Gelest DMS- V25) and 7 mg of platinum(II) acetylacetonate (platinum(II) acetylacetonate) (Aldrich). Wherein, the vinyl-terminated polydimethylsiloxane is an organosiloxane with a Si-H bond, and the photocrosslinkable group is a vinyl group with a carbon-carbon double bond. The above mixed solution was stirred at room temperature for 1 hour, and then the mixed solution was coated on the substrate by spin coating, wherein the spin rate of the spin coating was 3000 rpm and the coating time was 20 seconds. Next, set a photomask above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com