Electrodeless fluorescent lamp simulation lamp making device

A technology of electrodeless fluorescent lamps and phosphors, which is applied in the manufacture of tubes/lamp screens, the application of luminescent coatings, and the measurement/testing during the manufacturing process, which can solve the problems of time and material consumption, and achieve the goal of saving materials and reducing research and development costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

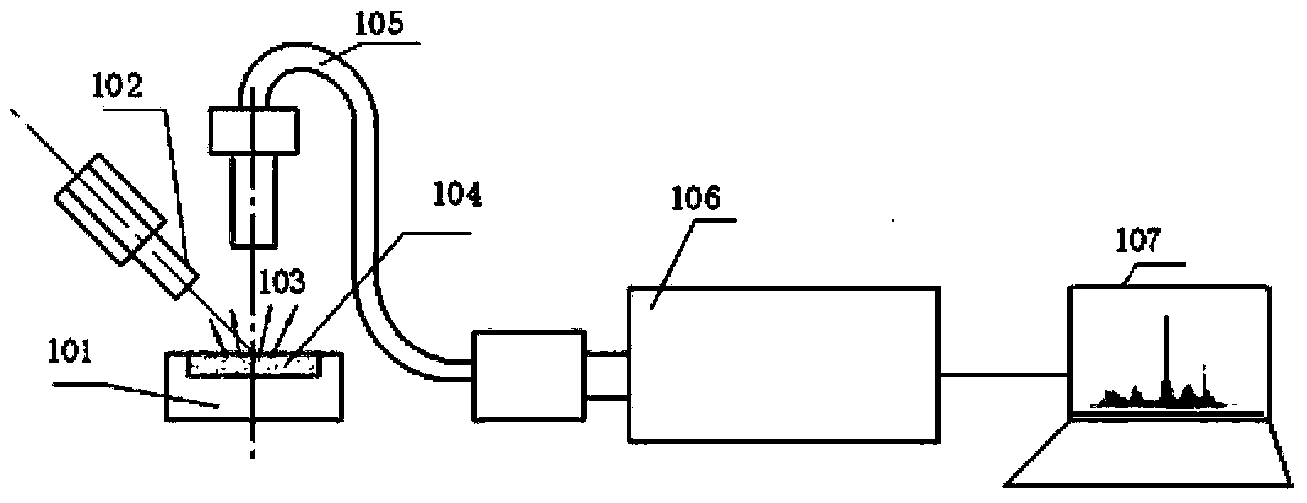

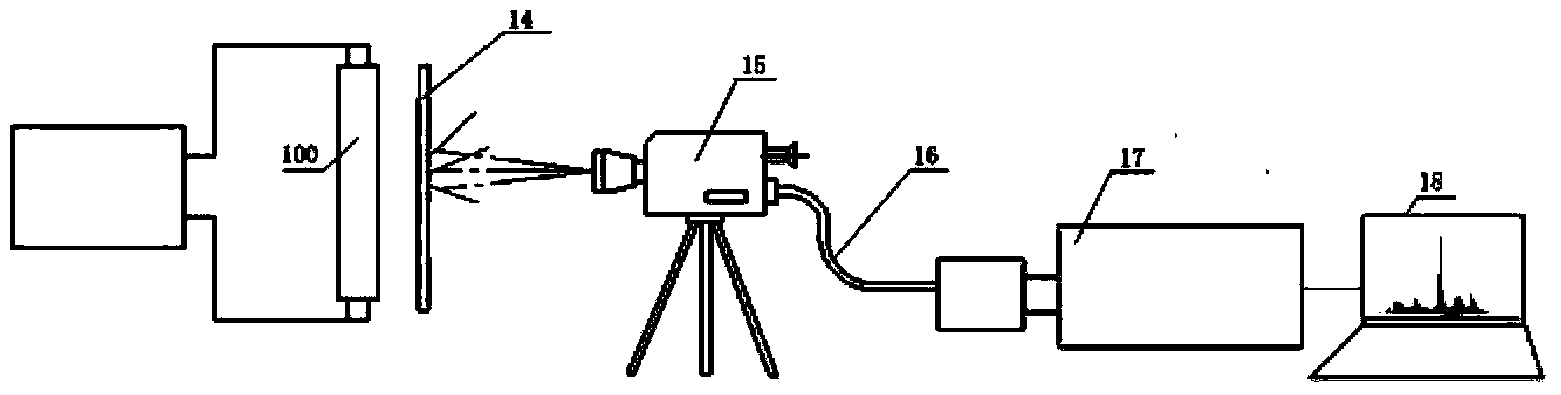

[0025] The present invention is a lamp-making technology for quickly completing the three-primary-color fluorescent powder formula used in electrodeless fluorescent lamps, which is called the lamp-making technology for simulating fluorescent lamps. This method can quickly simulate the ratio of phosphor powder, and determine the light and color parameters of the light source put into production, and can accurately simulate mass production of high color rendering light source. Hereinafter, it will be described in detail with reference to the drawings.

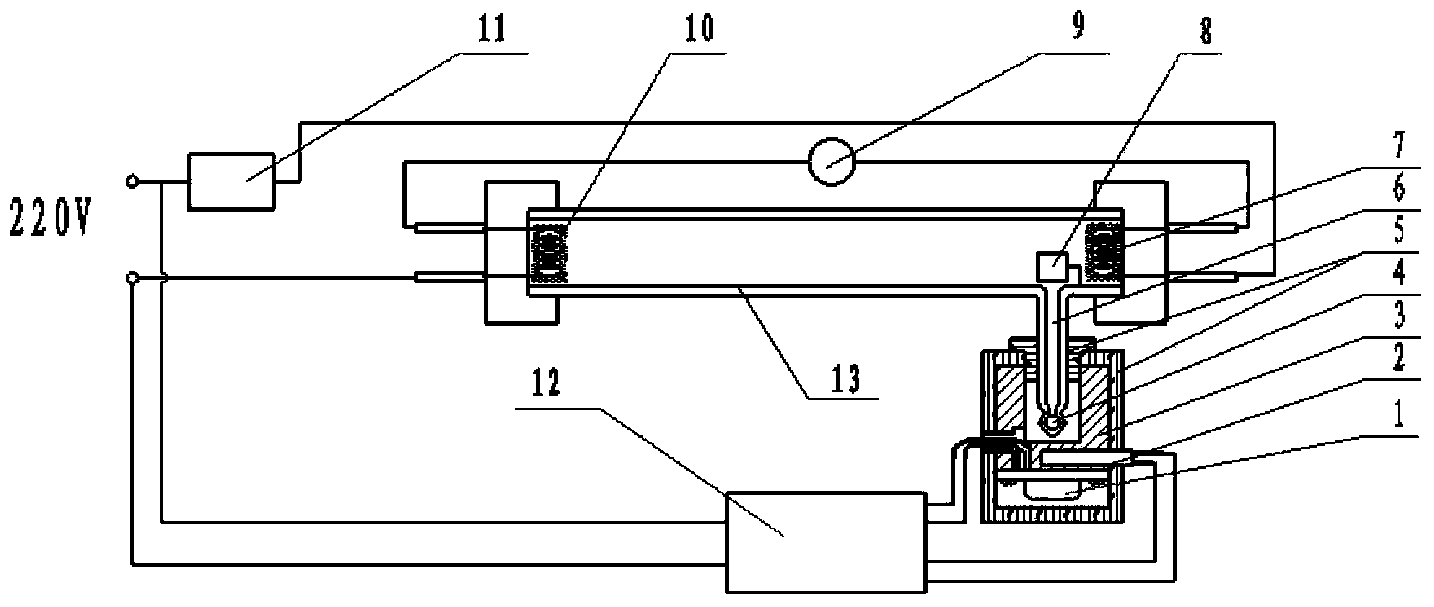

[0026] 1. First of all, it is necessary to manufacture a quartz ultraviolet excitation source similar to the internal spectrum composition of an electrodeless fluorescent lamp. The quartz glass that can penetrate the ultraviolet UVC band is used as the outer shell material of the ultraviolet lamp tube. The lamp tube 13 of the quartz ultraviolet excitation source can use solid amalgam Low-mercury vapor ultraviolet lamps, for quart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com