Plastic filler and preparation method thereof

A filler and plastic technology, applied in the field of plastic filler and its preparation, can solve the problems of high cost and low strength of plastic products, and achieve the effects of reducing usage, improving production efficiency and quality, and simplifying the proportioning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

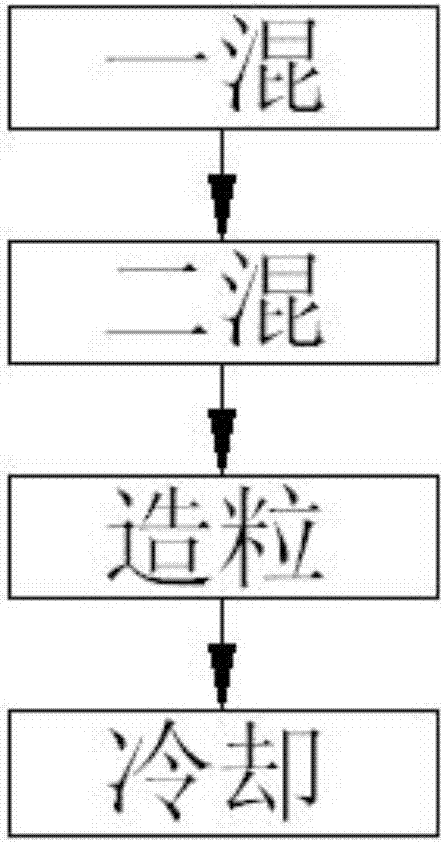

[0015] Such as figure 1 Shown, a kind of plastic filling material, this filling material comprises following composition: the talcum powder that the weight part is 38%, the calcium carbonate powder that the weight part is 38%, the plastic particle that the weight part is 14%, the weight part is 10% The auxiliary agent, the ratio of the talcum powder and calcium carbonate powder is 1:1, and the auxiliary agent is one or more combinations of polyethylene wax, stearic acid, and coupling agent.

[0016] The preparation of plastic filler in the present invention comprises the following steps:

[0017] 1) Once mixed, the talcum powder and calcium carbonate powder are continuously sent into the high-speed mixer and mixed to obtain a primary mixture. The mesh number of the talcum powder is 1500 mesh, and the mesh number of the calcium carbonate powder is 1500 mesh. Item, described high-speed mixer rotating speed is 1400r / min;

[0018] 2) Secondary mixing, the primary mixture, plasti...

Embodiment 2

[0023] Such as figure 1 Shown, a kind of plastic filler, this filler comprises following composition: the talcum powder that the weight part is 35%, the calcium carbonate powder that the weight part is 35%, the plastic particle that the weight part is 20%, the weight part is 10% The auxiliary agent, the ratio of the talcum powder and calcium carbonate powder is 1:1, and the auxiliary agent is one or more combinations of polyethylene wax, stearic acid, and coupling agent.

[0024] The preparation of plastic filler in the present invention comprises the following steps:

[0025] 1) Once mixed, the talcum powder and calcium carbonate powder are continuously sent into the high-speed mixer and mixed to obtain a primary mixture. The mesh number of the talcum powder is 1500 mesh, and the mesh number of the calcium carbonate powder is 1500 mesh. Item, described high-speed mixer rotating speed is 1200r / min;

[0026] 2) Secondary mixing, the primary mixture, plastic particles, and add...

Embodiment 3

[0031] Such as figure 1 Shown, a kind of plastic filler, this filler comprises following composition: the talcum powder that the weight part is 36%, the calcium carbonate powder that the weight part is 36%, the plastic particle that the weight part is 18%, the weight part is 10% The auxiliary agent, the ratio of the talcum powder and calcium carbonate powder is 1:1, and the auxiliary agent is one or more combinations of polyethylene wax, stearic acid, and coupling agent.

[0032] The preparation of plastic filler in the present invention comprises the following steps:

[0033] 1) Once mixed, the talcum powder and calcium carbonate powder are continuously sent into the high-speed mixer and mixed to obtain a primary mixture. The mesh number of the talcum powder is 1500 mesh, and the mesh number of the calcium carbonate powder is 1500 mesh. Item, described high-speed mixer rotating speed is 1300r / min;

[0034] 2) Secondary mixing, the primary mixture, plastic particles, and add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com