Reed, quartz crystal resonator and processing method

A processing method and resonator technology, applied in electrical components, impedance networks, etc., can solve the problems of reduced rigidity of reeds, reduced crystal stability, etc., and achieve the effects of enhanced rigidity, high reliability, and reasonable design of reed structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

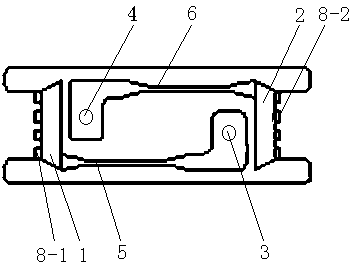

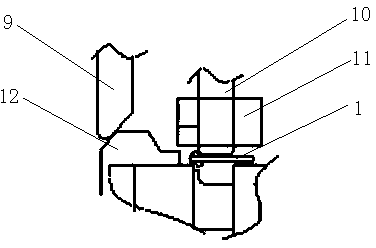

[0046] A reed in this embodiment includes a left reed 1 and a right reed 2 with opposite extension arms. The left reed 1 extends to the right side of the crystal through the extension arm I5 and is connected to the nail head of the right lead of the crystal. 3 spot welding connection, the right reed 2 extends to the left side of the crystal through the extension arm Ⅱ6 and is connected to the left lead nail head 4 of the crystal by spot welding, the extension arm Ⅰ5 and the extension arm Ⅱ6 are both turned 90 degrees with their length direction as the axis, After turning over 90 degrees, the extension arm Ⅰ5 and the extension arm Ⅱ6 are perpendicular to the horizontal plane of the left reed 1 and the right reed 2, and the left side of the left reed 1 and the right side of the right reed 2 are respectively equipped with The trough connecting line Ⅰ8-1 and the trough connecting line Ⅱ8-2.

Embodiment 2

[0048] A quartz crystal resonator of this embodiment, the reed includes a left reed 1 and a right reed 2 with opposite extension arms, the left reed 1 extends to the right side of the crystal through the extension arm I5 and is connected to The nail head 3 on the right lead of the crystal is connected by spot welding, and the reed 2 on the right side extends to the left side of the crystal through the extension arm II6 and is connected to the left nail head 4 of the crystal by spot welding. After the shaft is turned 90 degrees, it is perpendicular to the horizontal plane of the left reed 1 and the right reed 2 respectively, and the left side of the left reed 1 and the right side of the right reed 2 are respectively provided with groove-shaped connecting lines for easy cutting Ⅰ8-1, trough connection line Ⅱ8-2.

Embodiment 3

[0050] A kind of reed processing method of the present embodiment, comprises the following steps:

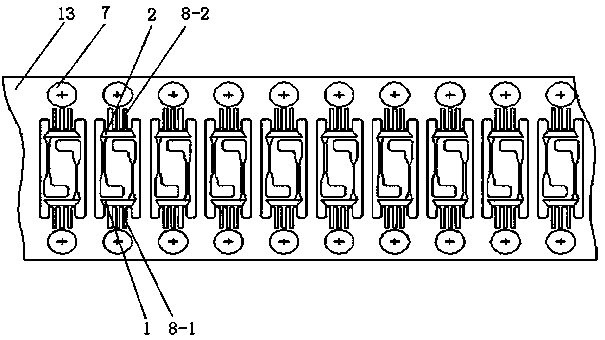

[0051] 1. Set the positioning hole

[0052] Positioning holes 7 are sequentially arranged at corresponding positions on both sides of the reed strip 13 in the length direction;

[0053] 2. Set the grooved connecting line

[0054] Cut out groove-shaped connection line I8-1 and groove-shaped connection line II8-2 on both sides of the length direction of the reed strip 13;

[0055] 3. Stamping

[0056] Two grooved connecting lines I8-1 and grooved connecting lines II8-2 in the width direction of the reed strip 13

[0057] The left reed 1 and the right reed 2 are stamped and formed between them to form the left reed 1 and the right reed 2 respectively having the extension arm I5 and the extension arm II6;

[0058] 4. The extension arm flips

[0059] Press both ends of the left reed 1 and the right reed 2, and turn the extension arm Ⅰ5 and extension arm Ⅱ6 90 degrees around their ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com