A kind of method and used device of melting trimellitic anhydride

A technology of trimellitic anhydride and aluminum bath, applied in the field of measurement and analysis, can solve the problems of severe temperature flushing, PID temperature control failure, rollover or rupture, etc., and achieve the effect of improving efficiency, uniform heat transfer and high melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

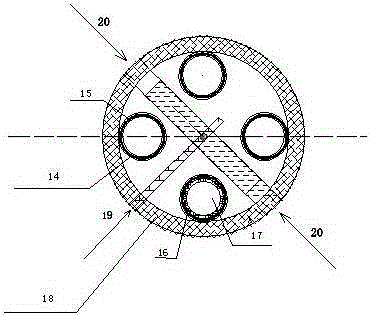

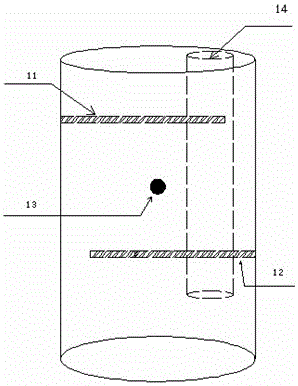

[0038] Melt trimellitic anhydride with an electric aluminum bath melting apparatus with 4 sample holes.

[0039] see figure 1 with figure 2 , is an aluminum bath block of a cylindrical electric aluminum bath melting instrument with 4 sample holes, and the cylindrical aluminum bath block is provided with a measurement area 17, a temperature stabilization area 18, a sample hole 14, an aluminum sleeve 15, and a temperature measurement hole 19 and heating holes 20;

[0040] For a cylindrical aluminum bath block with a height of 200.1±1.0mm and a diameter of 130.0±0.5mm, the 10mm thickness range near the edge of the cylindrical surface is the stable temperature zone 17, and the cylindrical area with a diameter of 110mm in the center of the aluminum bath block is the measurement zone 18 Drill 4 cylindrical sample-filled holes 14 vertically symmetrically in the center of the measuring area 18 cross-sections, the inner diameter of the sample-filled holes 14 is 31.0 ± 0.2mm, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com