Method of assembling an ultrasonic transducer and the transducer obtained thereby

A transducer, ultrasonic technology, applied in the use of vibration fluid, manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

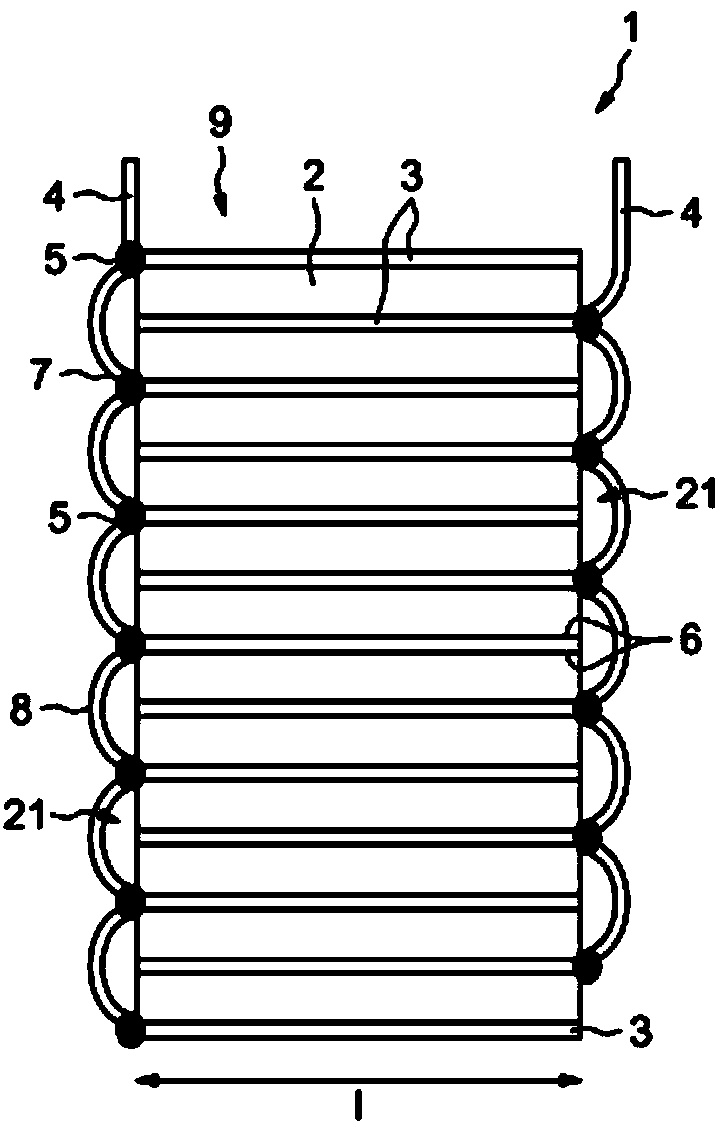

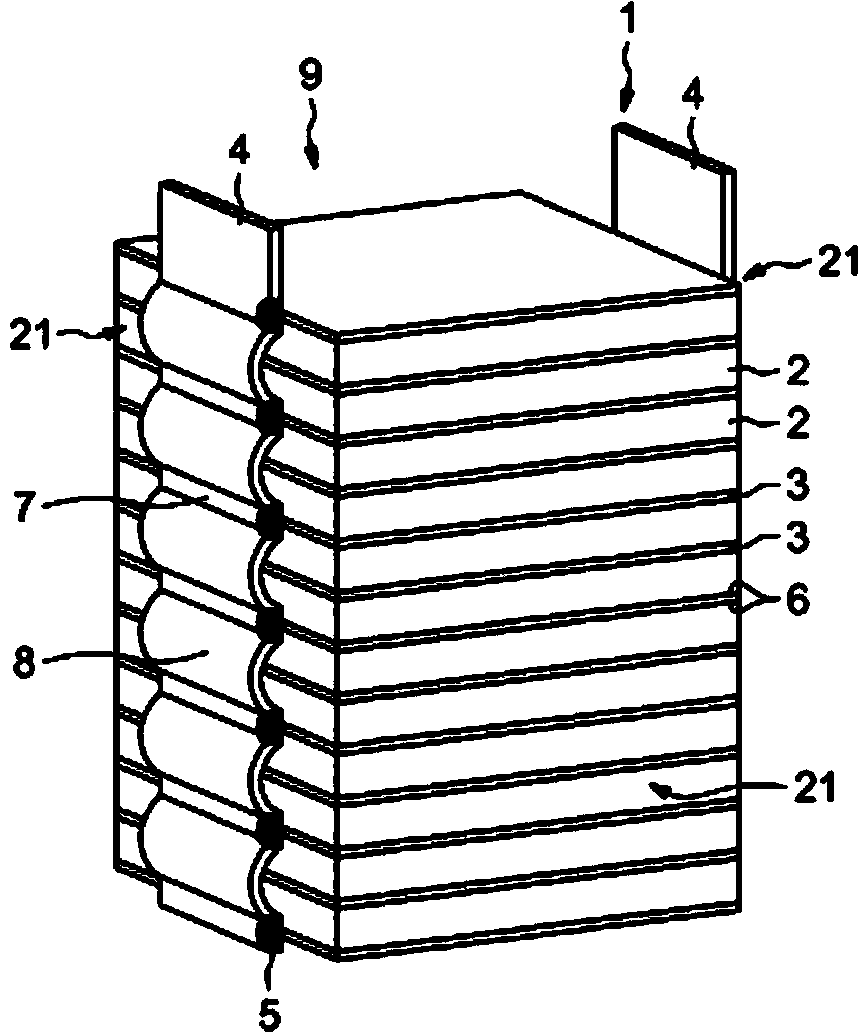

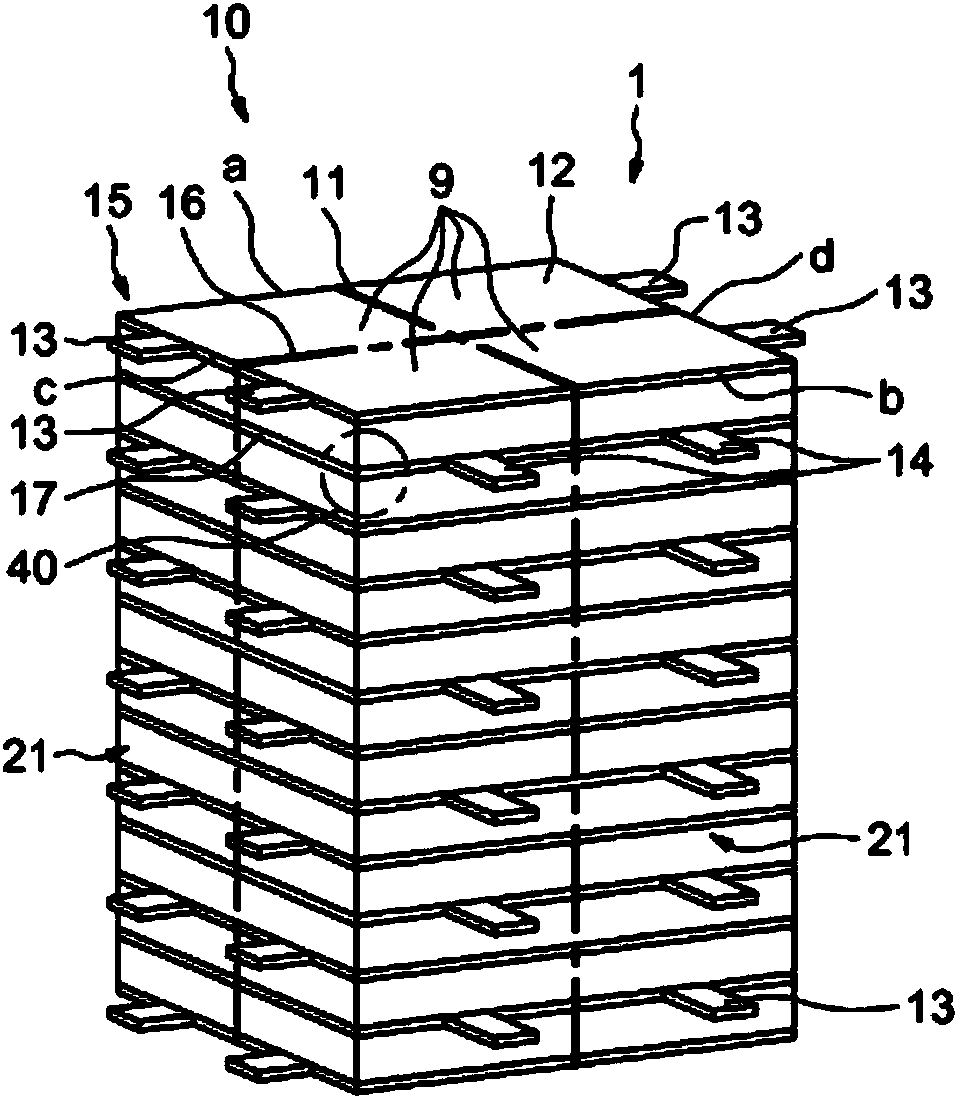

[0041] figure 1 is a schematic diagram of a transducer according to the invention. The transducer 1 comprises a plurality of ceramic wafers 2 , for example piezoelectric ceramic wafers, which alternate with a plurality of electrodes 3 . At the interfaces of the ceramics 2 and the electrodes 3 are arranged thin connection layers 6 which are typically between 10 and 50 microns and preferably between 10 and 30 microns in thickness. The electrodes are cut from rolled metal sheets, for example from sheets of annealed silver or copper beryllium alloy, or even from sheets of titanium alloy. The thickness of each intermediate electrode is greater than 20 microns, and preferably between 50 microns and 1 mm.

[0042] The thickness of these substantially rectangular or square profile wafer form ceramics is typically between 1 mm and 5 mm to be able to operate within the stress and frequency ranges required to produce a fuel injector. The width "1" of the stack 9 comprising alternating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Average temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com