Connecting structure

A technology for connecting structures and components, applied in the direction of connecting components, wardrobes, household appliances, etc., can solve the problems of increasing installation time and difficulty, inconvenient cleaning, and inability to mass-produce, and achieves simple and labor-saving processing and installation processes. The effect of convenient and fast construction and simple and easy construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and / or features.

[0026] Specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

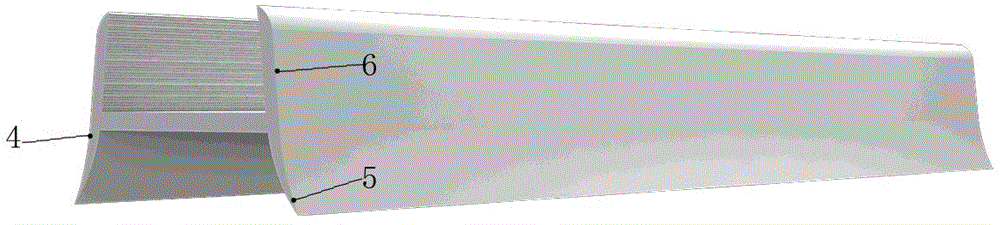

[0027] figure 1 It is a three-dimensional schematic view of the connecting member of the present invention. This figure shows an "H"-shaped member, and the "H"-shaped member 4 is a trumpet shape with one side opening larger than the other side opening, that is, the "H"-shaped member includes a large opening side part 5 and a small opening. The opening side part 6, wherein the large opening side part 5 and the small opening side part 6 are integrated.

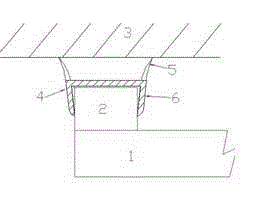

[0028] figure 2 for figure 1 A schematic cross-sectional view of the connecting member 4 as shown when it is joined to the war...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com