Rain-dirt separation device and rain-dirt separation method

A separation device and separation method technology, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of mechanical equipment operation loss, increased power consumption, time and labor consumption of operators, etc., and achieve low processing costs. , the effect of reducing the pollution load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical scheme of the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, which is believed to be clear to those skilled in the art.

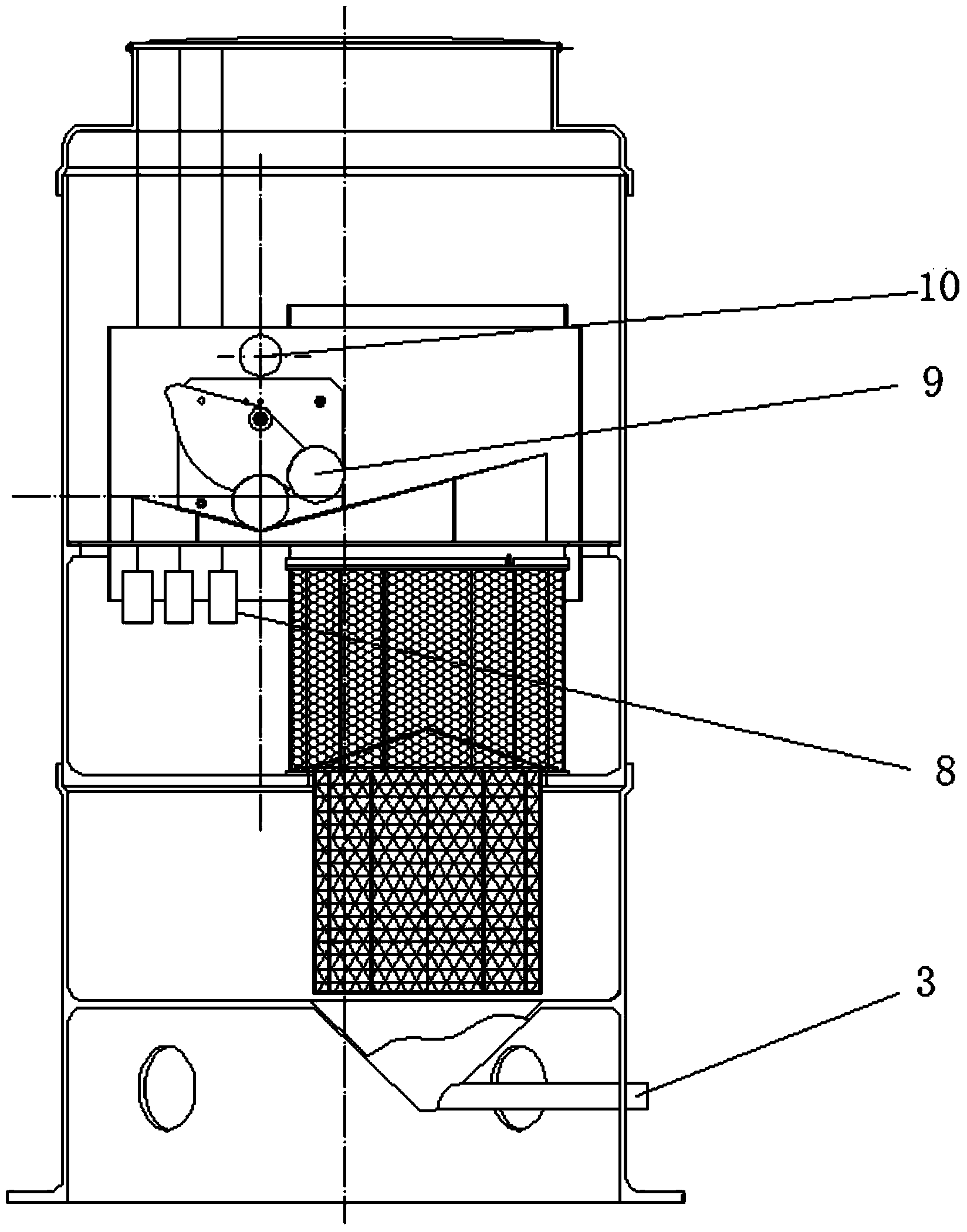

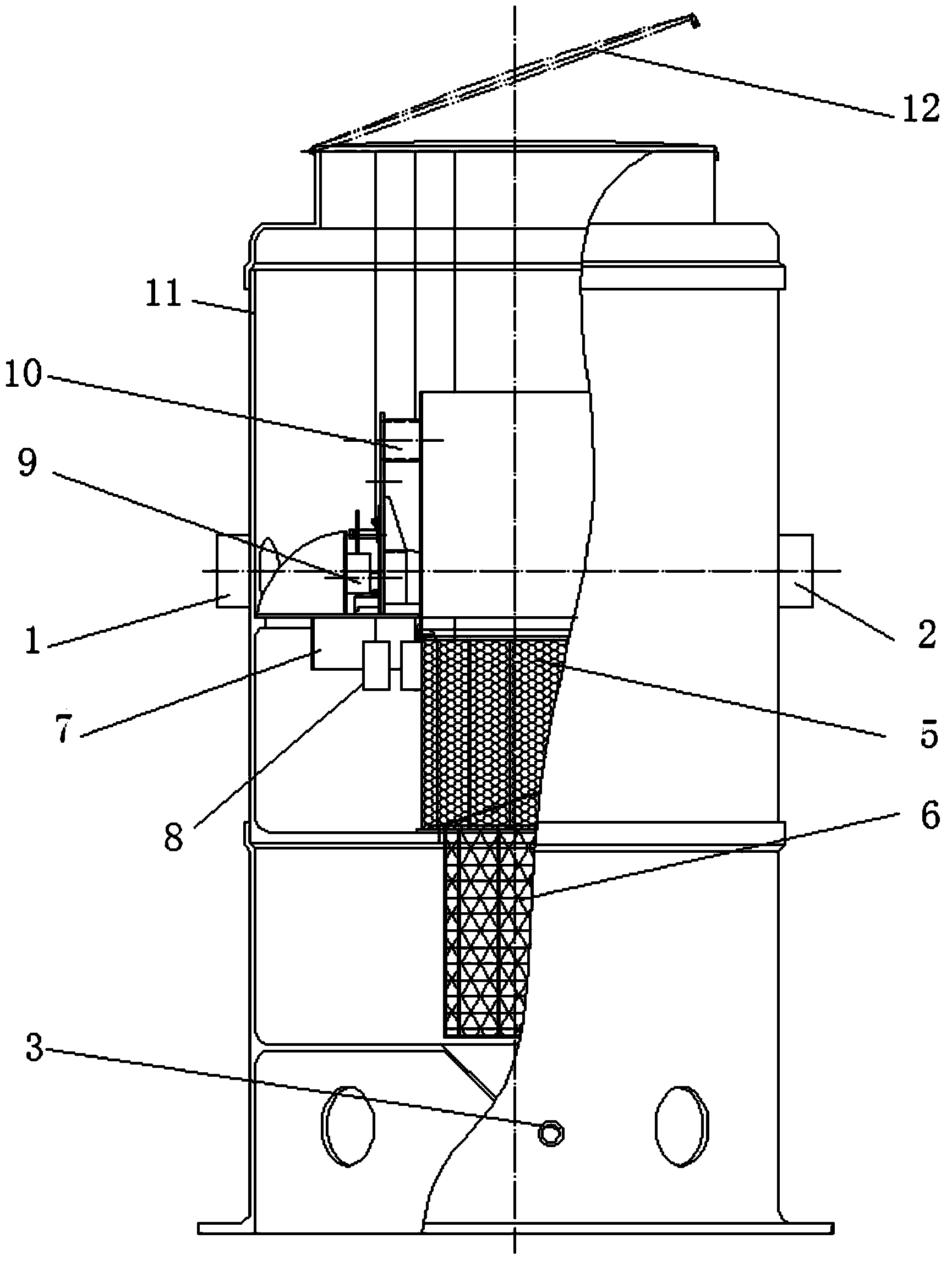

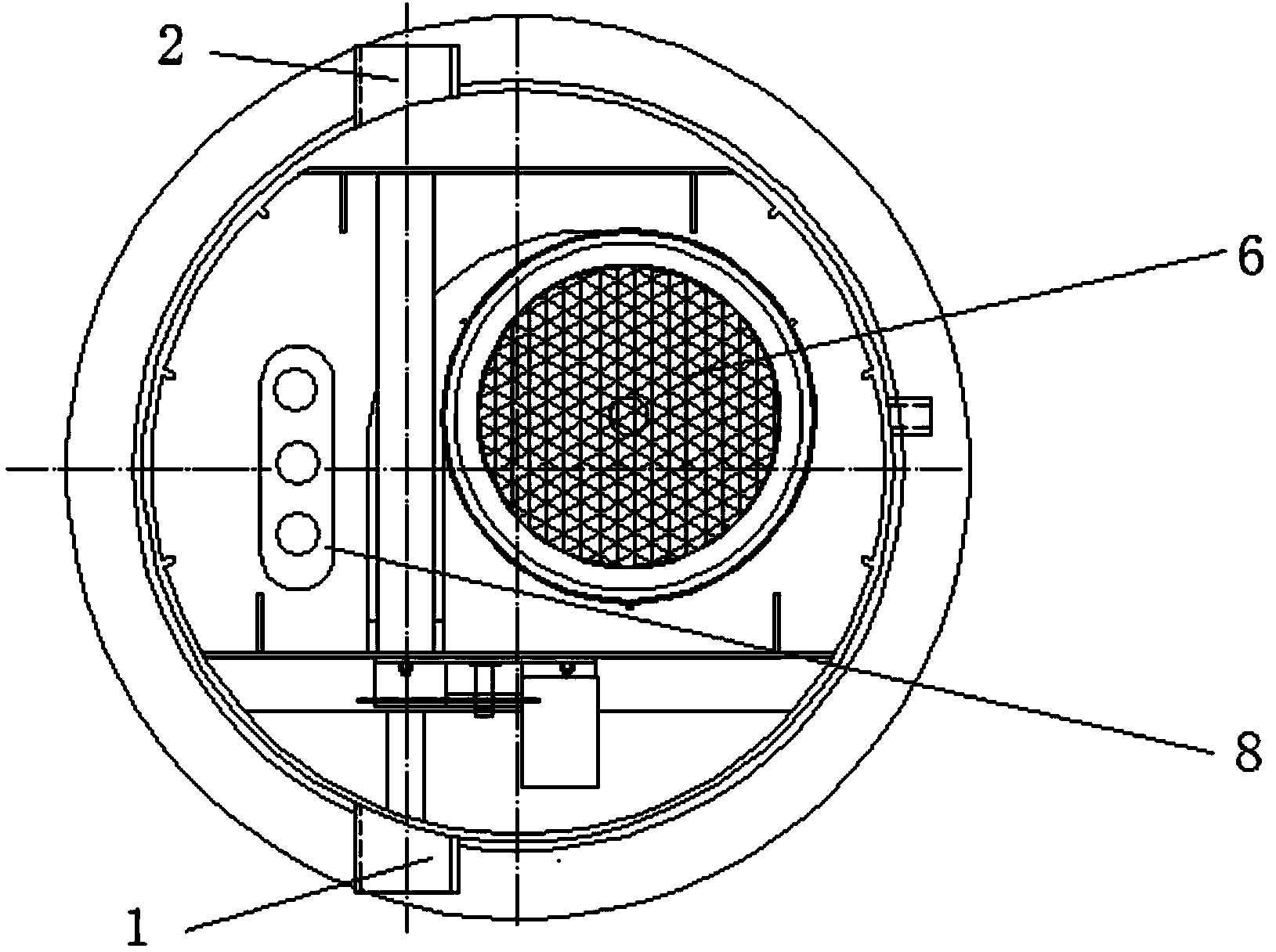

[0032] The rain and sewage separation device of this embodiment adopts 3,000 tons / day, 6,000 tons / day, 10,000 tons / day, 60,000 tons / day and other processing capacity in design specifications, and the maximum processing flow rate is 1,400 L / S (120,000 m3 / day) , and multiple separation stations can also be combined in parallel to adapt to larger water volumes. Such as Figures 1 to 3 As shown, it includes a cylinder, a water inlet 1, an outlet 2, a sewage nozzle 3 and a base. The cylinder 11 is arranged on the base, and the cylinder 11 is made of glass fiber reinforced plastic and is made in a modular manner. The cylinder 11 There are three upper, middle and lower cavities in sequence in the inner longitudinal direction. The cylinder can also be formed by vertically sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com