A high-temperature filter material production process for bag-type dust removal

A production process, bag-type dust removal technology, applied in the direction of filtration and separation, separation methods, non-woven fabrics, etc., can solve the problems of dependence on imports, less high-temperature-resistant synthetic fibers, etc., and achieve easy dust removal, high adsorption and long life, and improved filtration. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following will be described in detail in conjunction with the embodiments.

[0017] Selection of fiber raw materials:

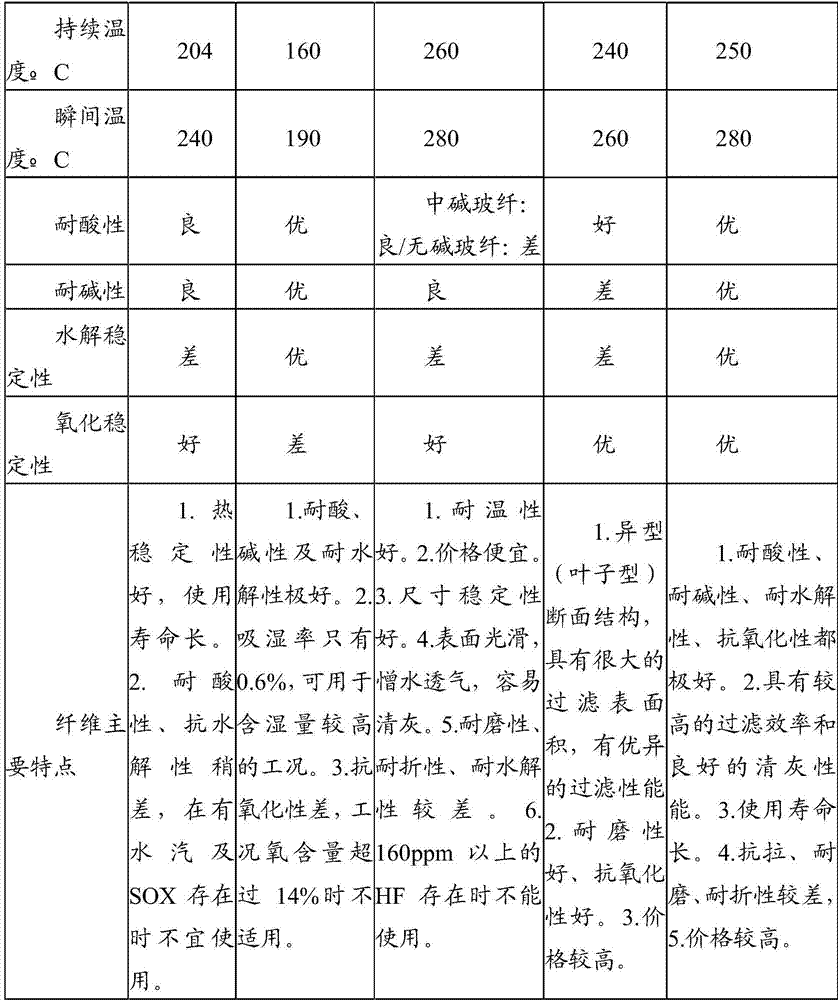

[0018] The performance comparison and analysis of several commonly used high temperature resistant fibers are shown in the following table:

[0019]

[0020]

[0021] P84 fiber: P84 fiber has high temperature resistance, the continuous use temperature can reach 240°C, and the instantaneous temperature can reach 260°C. In addition, because the P84 fiber has a special-shaped (leaf-shaped) cross-sectional structure, it has a large filtration surface area and excellent filtration performance. At the same time, it has good powder cake peeling performance during ash cleaning and is easy to clean. Therefore, the P84 fiber in this product is implanted into the surface layer of the filter material (the side facing the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com