Novel cyclone separator

A cyclone separator, a new type of technology, is applied in the direction of the cyclone device and the device whose axial direction of the cyclone can be reversed, etc. It can solve the problems that affect the separator to withstand high pressure and temperature loads, and the pressure of the crude gas is high. Improve the efficiency of dust removal and improve the effect of pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

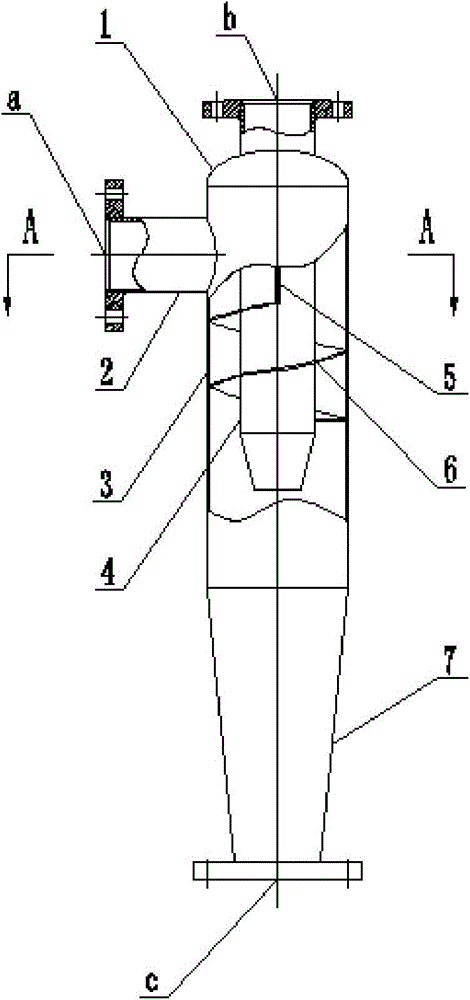

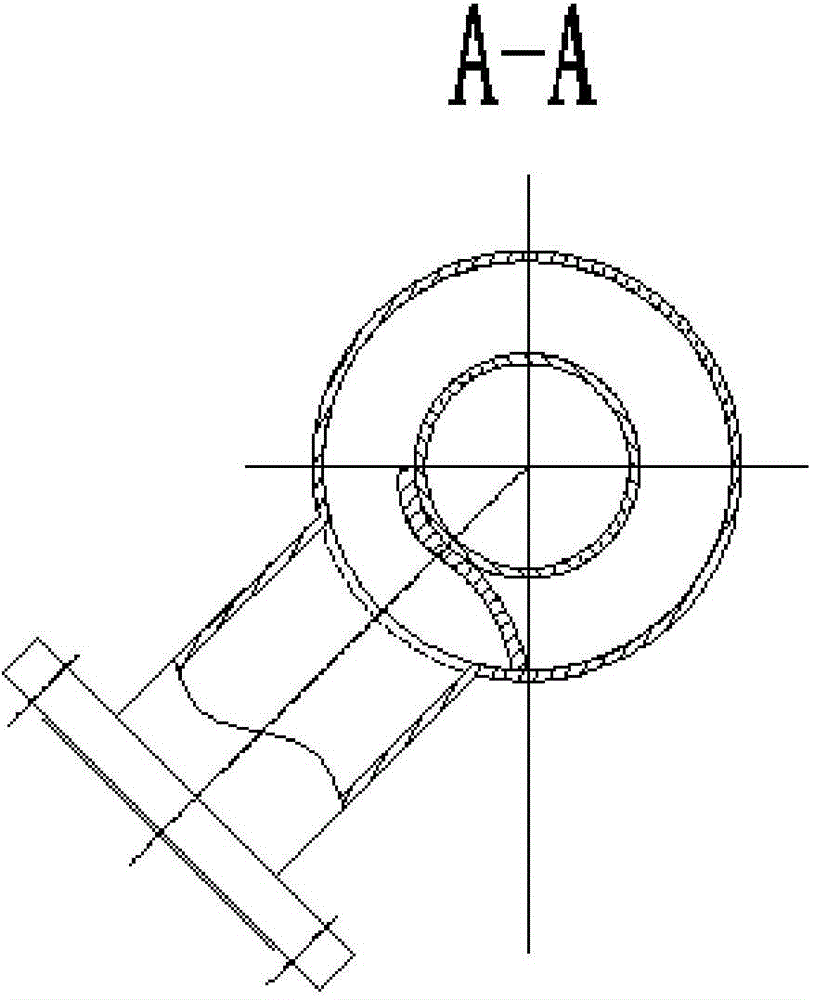

[0026] Such as Figure 1~2 As shown, it is a structural schematic diagram of a new cyclone separator, which consists of an oval head 1, an inlet pipe 2, a cylindrical cylinder 3, an exhaust pipe 4, an anti-erosion guide baffle 5, and a spiral guide vane 6 , Conical barrel 7 and other components.

[0027] The intake pipe 2 is a circular cross-section, one end is connected to the external dusty gas intake pipe through the flange a, and the other end is radially and vertically welded to the upper end of the cylindrical cylinder 3; the top of the cylindrical cylinder 3 is connected to the oval head 1 , the lower part is connected to the conical cylinder 7, and the bottom of the conical cylinder 7 is connected to the ash collecting hopper through the flange c; the exhaust pipe 4 is placed at the symmetrical axis of the cylindrical cylinder 3, and the lower end of the exhaust pipe 4 is contracted The outlet pipe has an oval head 1 protruding from the upper end, and is connected to ...

Embodiment 2

[0030] The number of rotations of the multi-layer spiral guide vane 6 is 1, and the helical inclination angle at the end is 15°. The dust-laden gas spirals downward along the multi-layer spiral guide blades, and the dust particles are thrown to the wall by the centrifugal force, and are discharged into the ash collecting hopper through the conical cylinder, and the clean gas is discharged from the exhaust pipe to realize gas solidification. separate. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com