A preparation method of integral fine-grain radial impeller casting

An impeller and casting technology, which is applied in the field of the preparation of alloy integral fine-grained radial impeller castings, can solve the problem of easy to produce casting cracks, easy to produce under-casting of the thin-walled structure of the centripetal impeller tip, and difficult overall fine-grained casting technology, etc. problems, to achieve the effect of refining grains, reducing component segregation and porosity, and easy forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the alloy integral fine grain centripetal impeller of the present invention, the method comprises the following steps:

[0033] (1) Alloy smelting: According to the chemical composition and proportion of the alloy, the master alloy ingot is melted and cast into a master alloy ingot by a vacuum induction furnace, and then the master alloy ingot is melted by a vacuum induction fine-grain casting furnace, and refined at 1450-1550°C for 3- 7 minutes, then cool down to the casting temperature, and the vacuum in the furnace is 0.1-5Pa;

[0034] (2) Casting process: the alloy treated in step (1) is cast to obtain a casting of an integral radial impeller, and the casting temperature is 1380-1450°C;

[0035] (3) Refining process: The grain size control process of the overall fine-grained radial impeller casting is to place the centrifugal impeller in step (2) in a bidirectional rotating electromagnetic field, and after standing for 8 to 30 seconds, appl...

Embodiment 1

[0046] The master alloy is smelted in a vacuum induction fine-grain casting furnace, and the whole fine-grain radial impeller is cast. The refining temperature is 1550°C, the refining time is 3 minutes, the vacuum degree is 0.1Pa, and the pouring temperature is 1450°C.

[0047] The whole fine-grained centripetal impeller after casting is placed in a two-way alternately rotating magnetic field. After standing still for 20 seconds, a 220A, 5Hz magnetic field is applied. The forward and reverse magnetic field rotation time is 30 seconds, and the reversing time is 5 seconds. After solidification, stop stirring. The alloy composition of this embodiment is shown in Table 1.

[0048] Table 1 Composition of the overall fine-grain phase-centric impeller (wt%)

[0049]

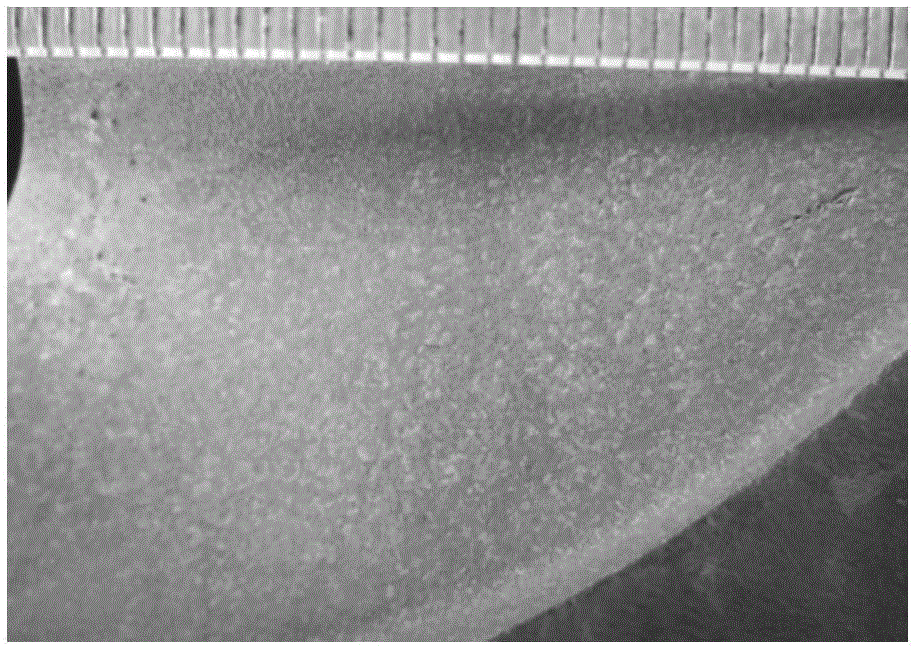

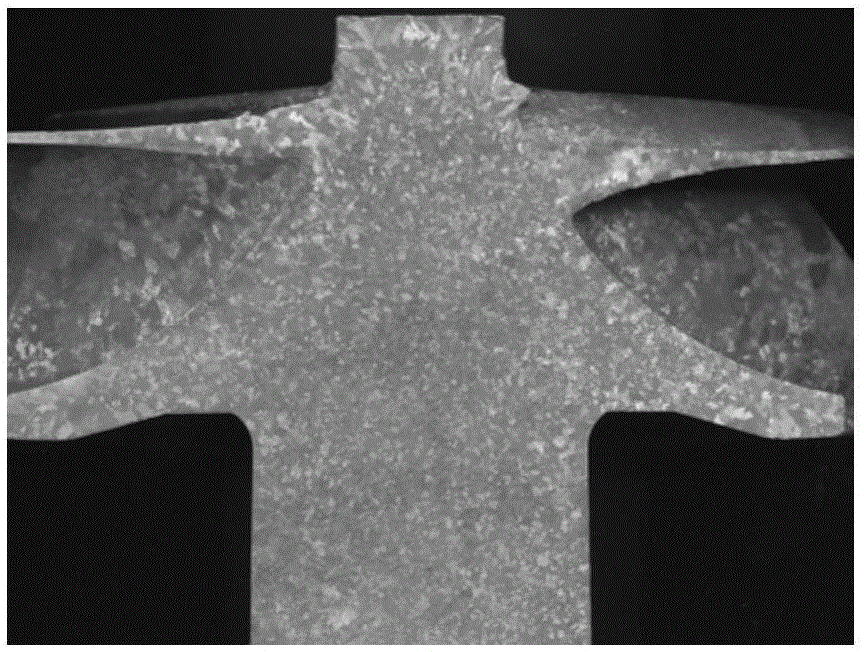

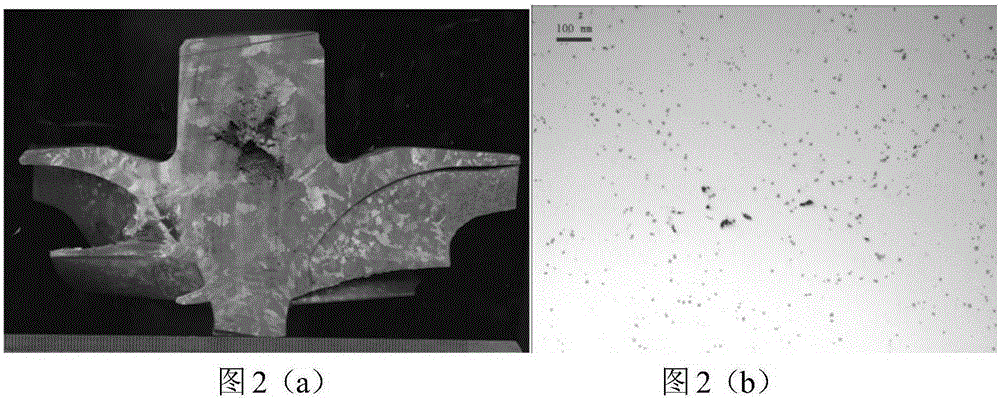

[0050] Figure 1(a) - Figure 1(b) It is the grain size of the integral fine-grained radial impeller cast in this embodiment. It can be seen that after the bidirectional rotating electromagnetic field is applied, t...

Embodiment 2

[0063] The difference from Example 1 is that the composition of the alloy for the casting of the radial impeller in this example is shown in Table 3.

[0064] Table 3 Alloy composition (wt%) for radial impeller castings

[0065]

[0066] After the centripetal impeller is refined by two-way electromagnetic rotation, heat treatment is carried out. The process is as follows:

[0067] (1) The master alloy is melted in a vacuum induction fine-grain casting furnace, and the overall fine-grain radial impeller is cast. The refining temperature is 1520°C, the refining time is 3 minutes, the vacuum degree is 0.1Pa, and the pouring temperature is 1420°C.

[0068] (2) After casting, the overall fine-grained centripetal impeller is placed in a two-way alternately rotating magnetic field. After standing for 10 seconds, a 300A, 12Hz magnetic field is applied. The forward and reverse magnetic field rotation time is 20 seconds, and the reversing time is 2 seconds. After the casting is com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com