Wood antiquing agent and application thereof

A wood and wood surface technology, applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of unnatural effect, dirty wood surface, complicated process, etc., and achieve the effect of increasing added value, natural effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Dry a rosewood log strip with a length of 30cm, a width of 10cm, and a thickness of 1cm to a moisture content of 10%;

[0030] 2) Clean the surface of the dried rosewood log to make it free of stains;

[0031] 3) will K 2 CO 3 , KMnO 4 Mix with water to prepare 100g of old agent, in which K 2 CO 3 The mass concentration is 1.5%, KMnO 4 The mass concentration is 0.25%, and the solvent is water;

[0032] 4) Apply the prepared old agent evenly on the surface of rosewood wood strips for 3 times, taking the wood surface to fully absorb (that is, completely wet) as the standard;

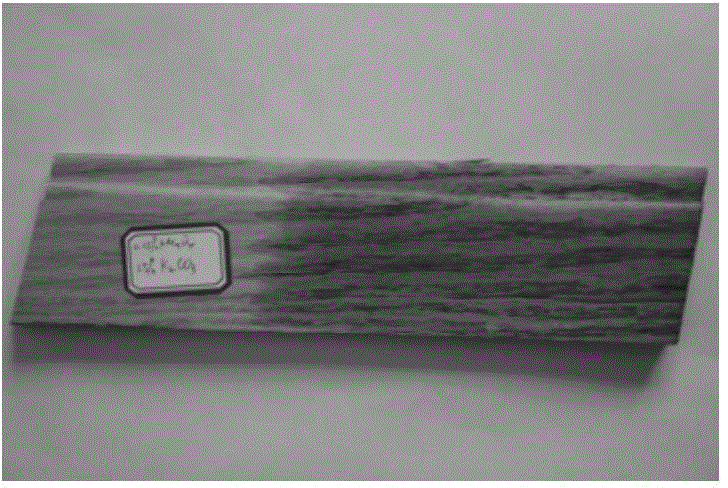

[0033] 5) Let it dry naturally Dry Afterwards, the smear has penetrated into the wood fibers, and the original bright color of rosewood becomes old, showing a sense of old vicissitudes, and the effect of aging is natural and harmonious, see figure 1 .

Embodiment 2

[0035] 1) Dry an oak log strip with a length of 30cm, a width of 10cm and a thickness of 1cm to a moisture content of 10%;

[0036] 2) Clean the surface of the dried oak logs to make them free of stains;

[0037] 3) will K 2 CO 3、 KMnO 4 Mix with water to prepare 100g of old agent, in which K 2 CO 3 The mass concentration is 1.5%, KMnO 4 The mass concentration is 0.25%, and the solvent is water;

[0038] 4) Apply the prepared old agent evenly on the surface of oak log strips for 3 times, taking the wood surface to fully absorb (that is, completely wet) as the standard;

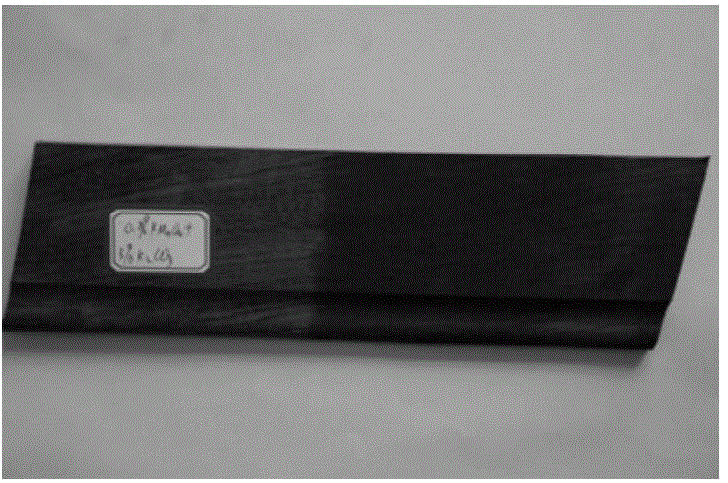

[0039] 5) After natural drying, the smear penetrates into the inside of the oak fiber, and the color of the wood becomes darker and older, showing a sense of old vicissitudes, and the surface texture is clearer, and the effect of aging is natural and harmonious, see figure 2 . Example 3:

Embodiment 3

[0040] 1) Dry a rosewood log strip with a length of 30cm, a width of 10cm, and a thickness of 1cm to a moisture content of 10%;

[0041] 2) Clean the surface of the dried rosewood log to make it free of stains;

[0042] 3) will K 2 CO 3 , KMnO 4 Mix with water to prepare 100g of old agent, in which K 2 CO 3 The mass concentration is 3%, KMnO 4 The mass concentration is 0.25%, and the solvent is water;

[0043] 4) Apply the prepared old agent evenly on the surface of rosewood strips for 3 times, taking the wood surface to fully absorb (that is, completely wet) as the standard;

[0044] 5) After natural drying, the smear has penetrated into the interior of the wood fiber, the original bright color of rosewood becomes older, darker, and the vicissitudes of the old vicissitudes are more obvious, and the old effect is also natural and harmonious, see image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com