Production technology and production equipment of desulfurization and denitrification active coke using multi-stage furnace

A nitric acid active coke and production process technology, applied in the field of multi-stage furnace manufacturing desulfurization and denitrification active coke production process and production equipment, to achieve the effect of better control of the heating rate and elimination of appearance defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to deepen the understanding of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0035] A specific embodiment of the present invention is,

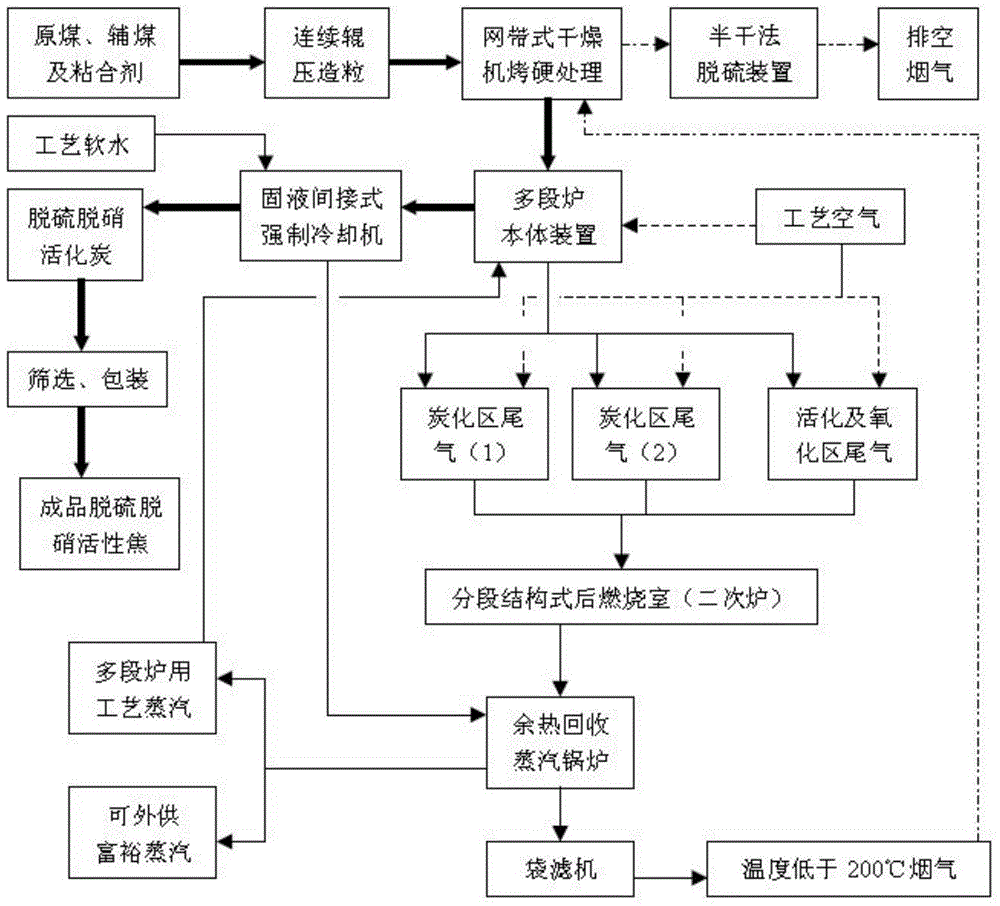

[0036] The production process of desulfurization and denitrification active coke is manufactured by using a multi-stage furnace, including the following steps:

[0037] a. Granulation, the raw coal, auxiliary coal and binder are sent to the rolling granulation device for continuous rolling granulation;

[0038] b. Bake hard, send the roll-formed granules to the mesh belt dryer to bake hard, and the tail gas generated during the drying process is sent to the semi-dry desulfurization device;

[0039] c. Carbonization, activation, and oxidation. The ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap