Production method for portable self-spraying bi-component foam caulking agent

A technology of foam caulking agent and production method, applied in the direction of chemical instruments and methods, other chemical processes, etc., can solve the problems of slow curing time, short storage period, not easy to carry, etc., achieve short curing time, long shelf life, and provide work efficiency effect

Inactive Publication Date: 2014-05-28

BEIJING DONGCHEN RUIFENG CHEM

View PDF1 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] There are more domestic reports on two-component polyurethane composite materials, which are widely used in exterior walls, pipes, and cold storage insulation industries. Special equipment is required, the investment is high, and it is not easy to carry. There are no reports on door and window filling.

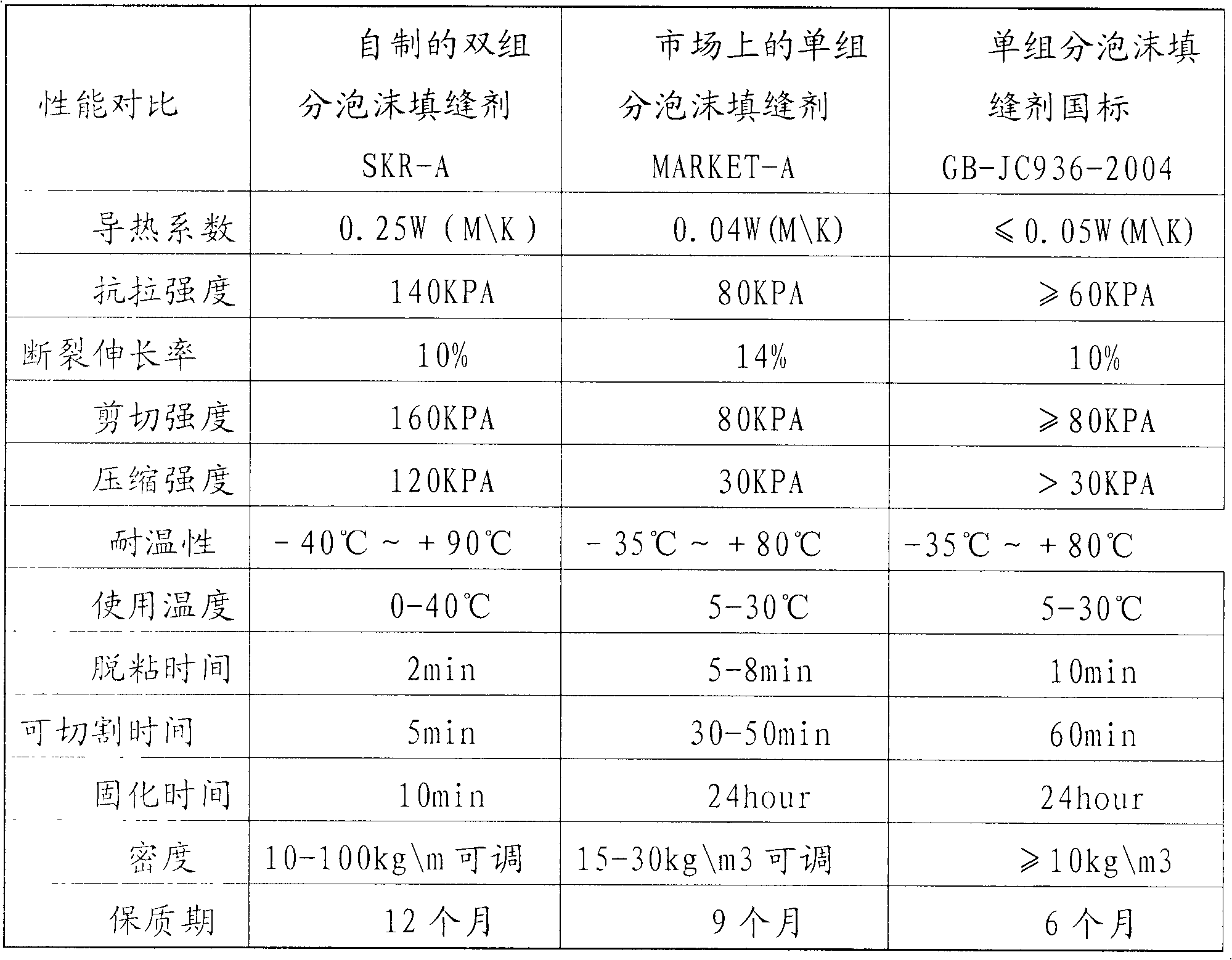

[0004] It can be said that the polyurethane foam sealant used in the door and window filling and sealing industry in the domestic market is all in the form of a single component, but the single-component foam sealant has the defects of slow curing time, short storage period, and easy pulverization in winter. The invention introduces a production method of a two-component foam caulking agent, which is simple in operation and low in cost, and needs to be used in conjunction with another patent (two-component foam caulking agent glue gun) applied by our company.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a production method for a portable self-spraying bi-component foam caulking agent. Polyols (polyether polyol, polyester polyol and vegetable oil polyol), a catalyst, silicone oil, a foaming agent, other accessories and the like are poured into a special galvanized iron pot, and are injected with a propellant to form a component A; one or more of crude MDI (diphenyl-methane-diisocyanate), liquefied MDI or prepolymers thereof are poured into another special galvanized iron pot, and are injected with the propellant to form a component B. When the portable self-spraying bi-component foam caulking agent is used, pot valves of the components A and B are opened, and the two components are mixed through a mixing gun for foaming formation after being automatically sprayed.

Description

technical field [0001] The invention relates to a production method of a portable self-spraying type two-component foam caulking agent. Background technique [0002] Polyurethane foam caulking agent is commonly known as foaming agent, styrofoam, PU caulking agent, etc. PU FOAM in English is the product of the cross combination of aerosol technology and polyurethane foam technology. It is a special polyurethane product filled with polyurethane prepolymer, blowing agent, catalyst and other components in a pressure-resistant aerosol can. When the material is sprayed from the aerosol can, the foamy polyurethane material will expand rapidly and react with the air or the moisture in the contacted substrate to form a foam. The cured foam has multiple effects such as caulking, bonding, sealing, heat insulation, and sound absorption. It is an environmentally friendly, energy-saving, and easy-to-use building material. Sound insulation, especially suitable for sealing and waterproofi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08G18/76C08G18/78C08G18/67C08G18/48C08G18/42C09K3/10C08G101/00

CPCC08G18/36C08G18/7664C08G18/7843C08G18/797C08G2101/00C08G2190/00C08G2115/06

Inventor 韩志成张汉岭

Owner BEIJING DONGCHEN RUIFENG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com