Construction method for subway station body

A construction method and technology for subway stations, applied in building construction and the construction field of the main body of subway stations, can solve the problems of long construction period, poor safety risk control, and low efficiency, and achieve the effects of short construction period, safe construction, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is a kind of construction method of subway station main body, and it comprises following technological steps:

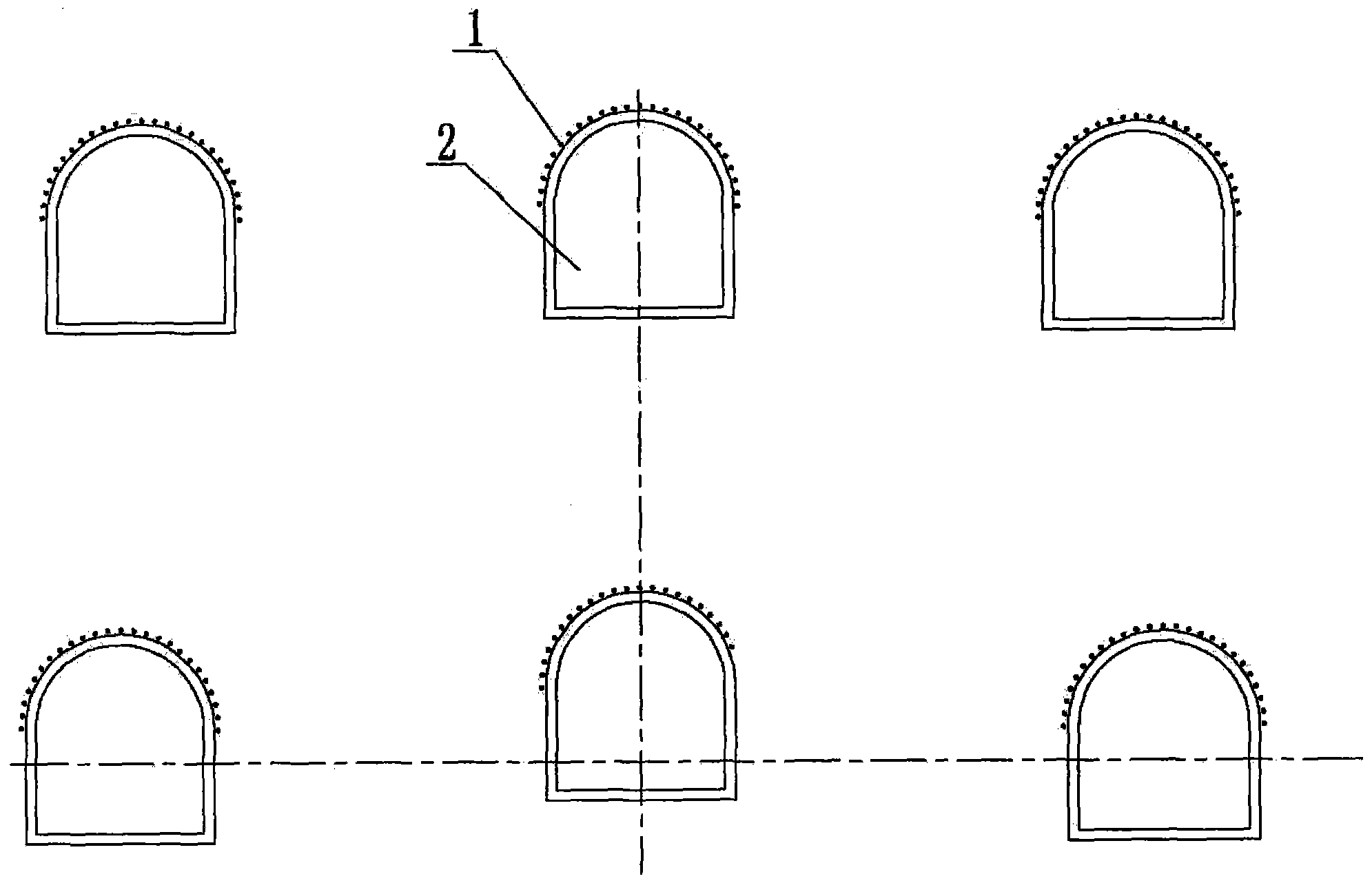

[0035] 1), through the pre-grouting of the advanced small conduit 1 to strengthen the formation, excavate the pilot tunnel 2, and implement the initial support; when excavating the pilot tunnel, first excavate the lower pilot tunnel and then excavate the upper pilot tunnel After the pilot tunnel, the pilot tunnel is excavated; among them, the pilot tunnel is excavated by step method;

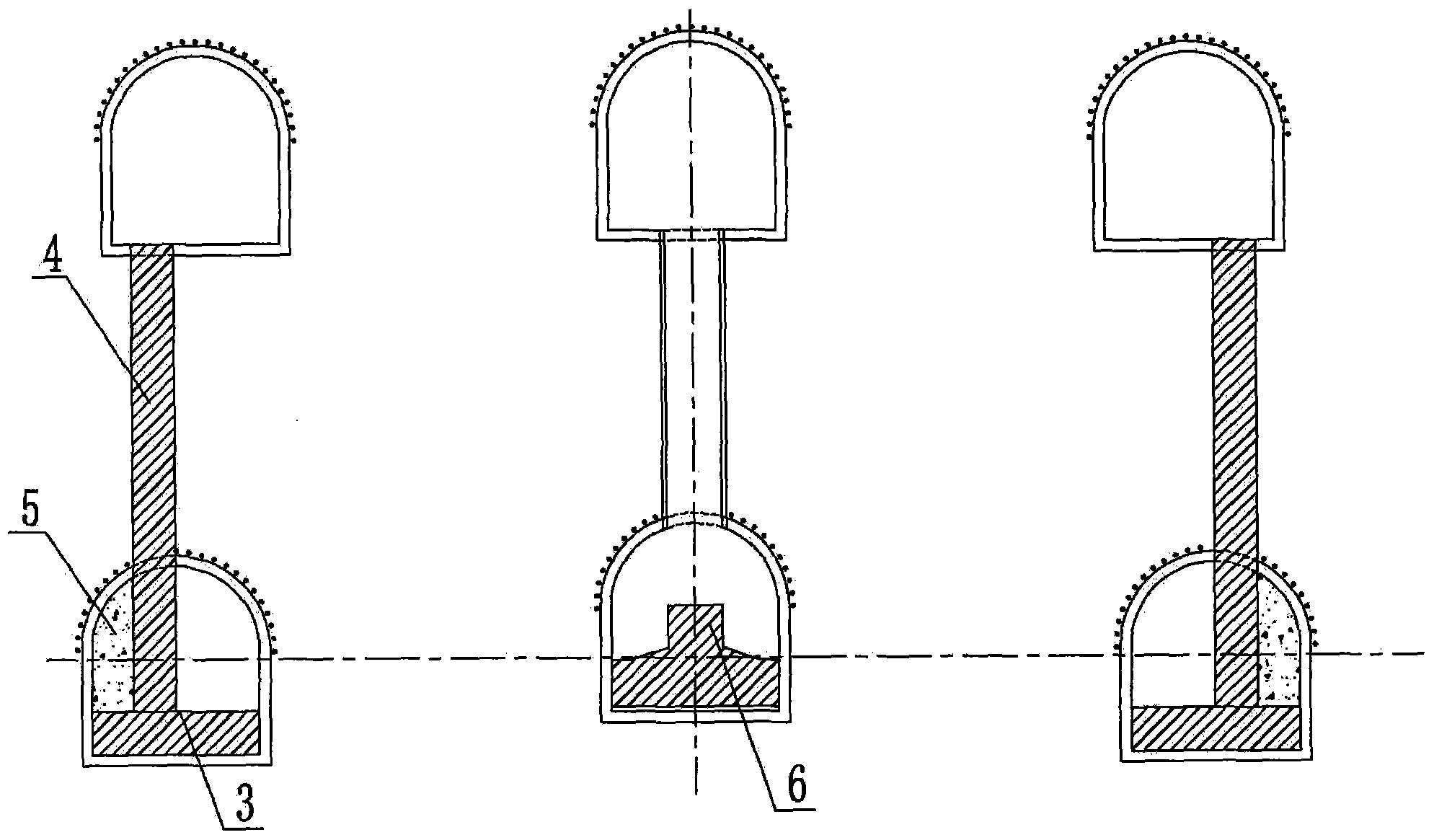

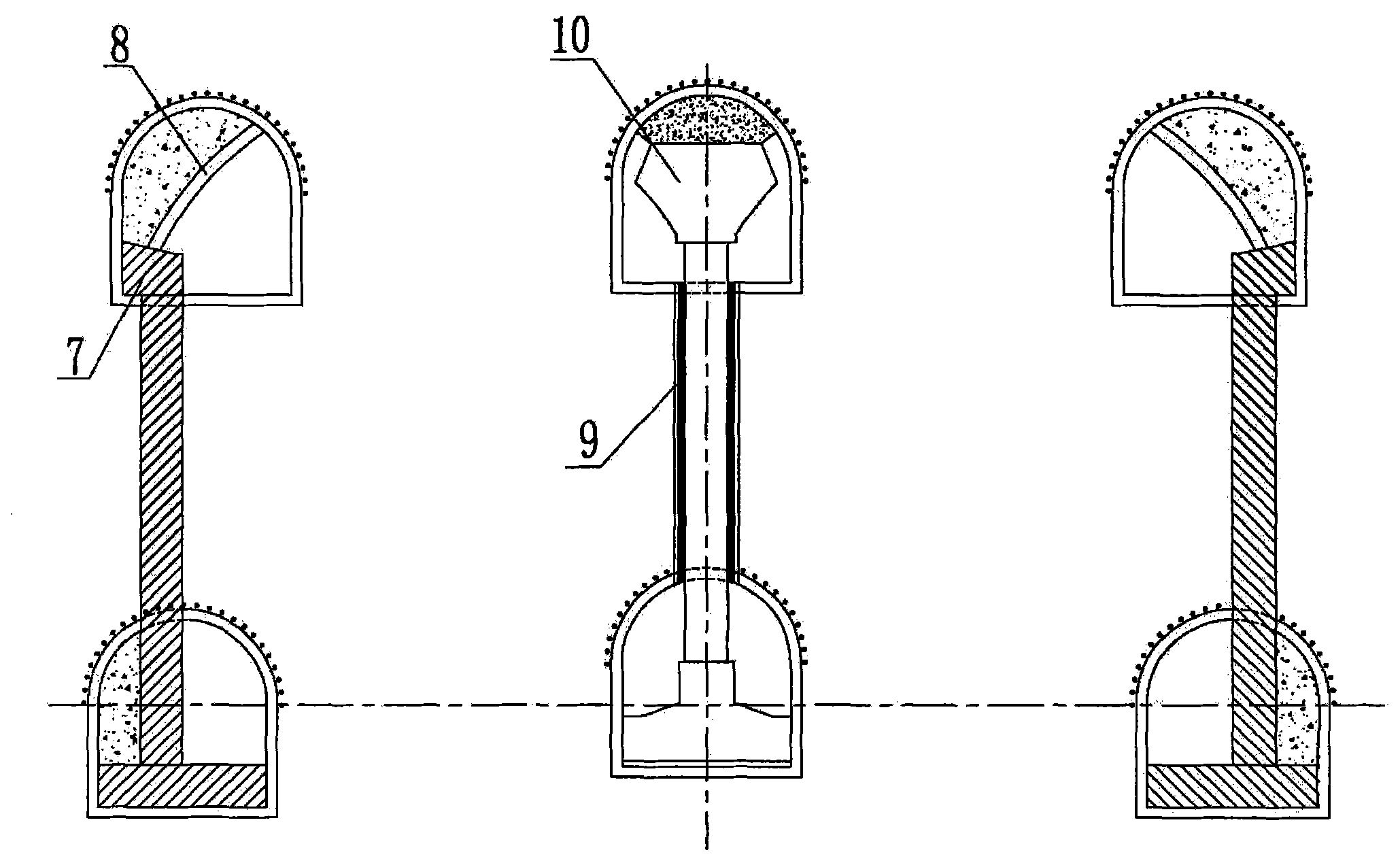

[0036] 2), after the lower pilot tunnel is penetrated, step back and construct the strip foundation 3 in the lower pilot tunnel; construct side piles 4 in the upper pilot tunnel, and backfill with C20 concrete 5 between the outside of the side piles and the pilot tunnel; construct in the middle pilot tunnel Digging holes for concrete-filled steel pipe columns between the upper and lower pilot tunnels, and the bottom longitudinal beam 6 of the middle column;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com