Hydraulic control system for anti-jamming of rock drill

A hydraulic control system and technology for rock drills, which are applied to mechanical equipment, reciprocating drilling rigs, fluid pressure actuating devices, etc. Good performance and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

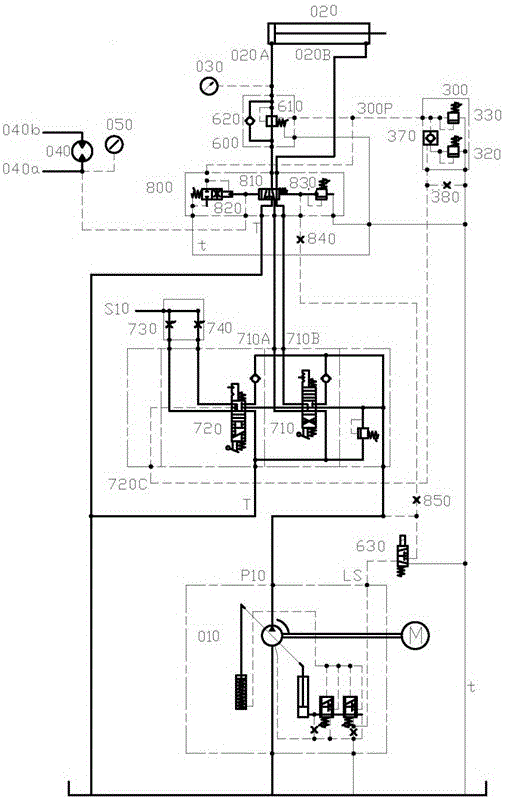

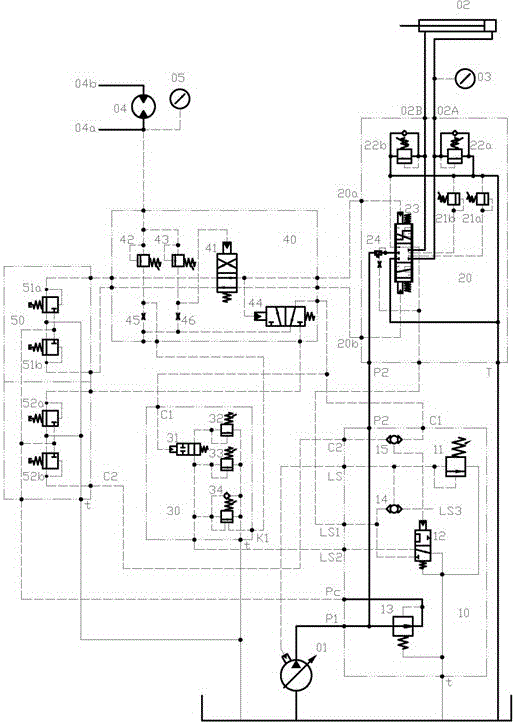

[0026] like figure 2 As shown, an anti-jamming hydraulic control system of a rock drill includes a variable pump 01 controlled by LS, a rock drilling impact valve block 10, a propulsion control valve group 20, a propulsion pressure regulating valve block 30, an anti-jamming valve block 40 and a pilot handle Control valve group 50 .

[0027]The outlet of the variable pump 01 is connected to the oil inlet port of the propulsion control valve group 20 and the pressure reducing valve 13 in the rock drilling impact valve block 10. The output of the pressure reducing valve is used as the pilot control oil source Pc of the pilot handle to control the weight of the rock drill. After the pilot oil of the impact handle is controlled by the hydraulic directional valve 41 of the anti-jamming valve block 40, it is connected to both ends of the shuttle valve 15 of the rock drilling impact valve block 10 together with the pilot oil of the light impact control handle. The output of the rock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com