Compressed air engine hydraulically controlled high pressure intake system

A high-pressure air intake, compressed air technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as high-pressure air switches that are difficult to solve, reduce pressure, reduce preload, and facilitate The effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

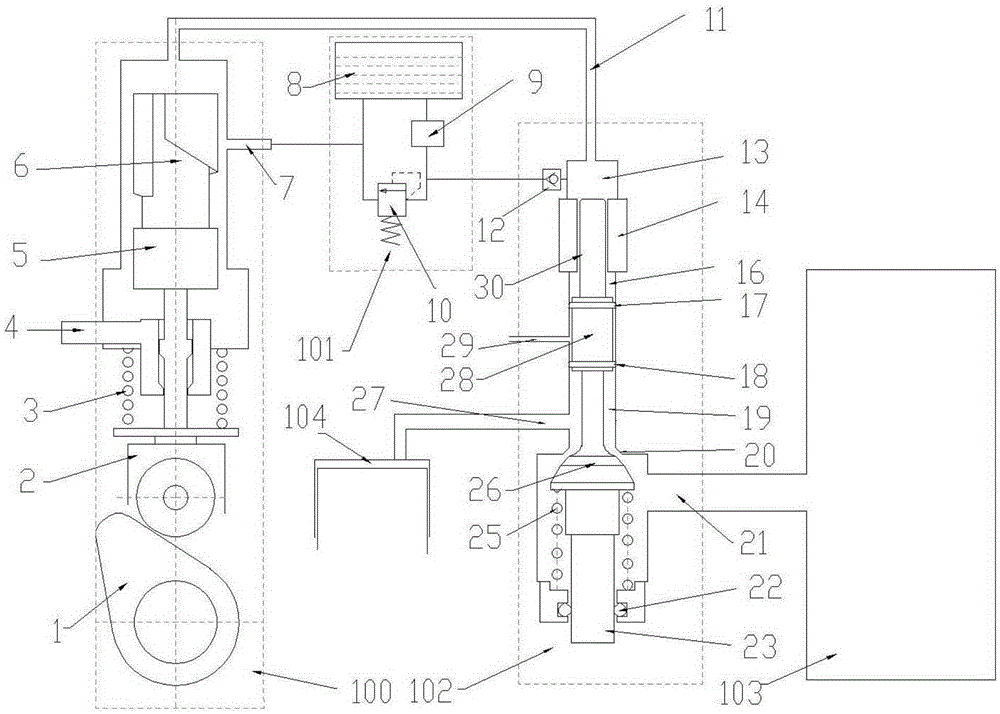

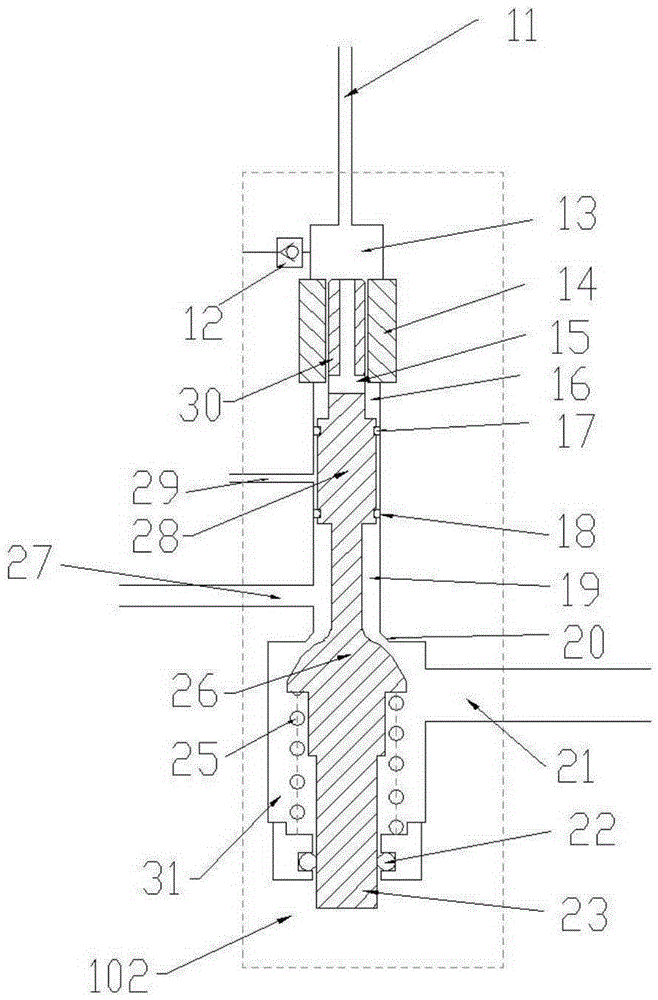

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] The compressed air engine hydraulically controls the high-pressure intake system, which is composed of a high-pressure oil pump 100, a high-pressure intake valve 102, a high-pressure gas tank 103 and a low-pressure oil delivery system 101; the low-pressure oil delivery system 101 provides the source of hydraulic oil required by the entire system; the high-pressure oil pump 100 provides the opening frequency and angle of the high-pressure intake valve 102 ; the high-pressure intake valve 102 inputs the high-pressure gas from the high-pressure gas tank 103 into the combustion chamber 104 .

[0022] The high-pressure oil pump 100 adopts a modified cam hydraulic plunger structure, cancels the oil inlet hole, retains the oil outlet hole 7, heightens the top surface of the hydraulic plunger 5, and the top of the hydraulic plunger 5 is always higher than the oil outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com