Single row planetary gear train two-gear automatic mechanical transmission for electrocar

A single-row planetary and electric vehicle technology, applied to mechanical equipment, transmission devices, transmission device parts, etc., can solve problems such as high cost and small transmission ratio range, and achieve the effect of saving power and smooth shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

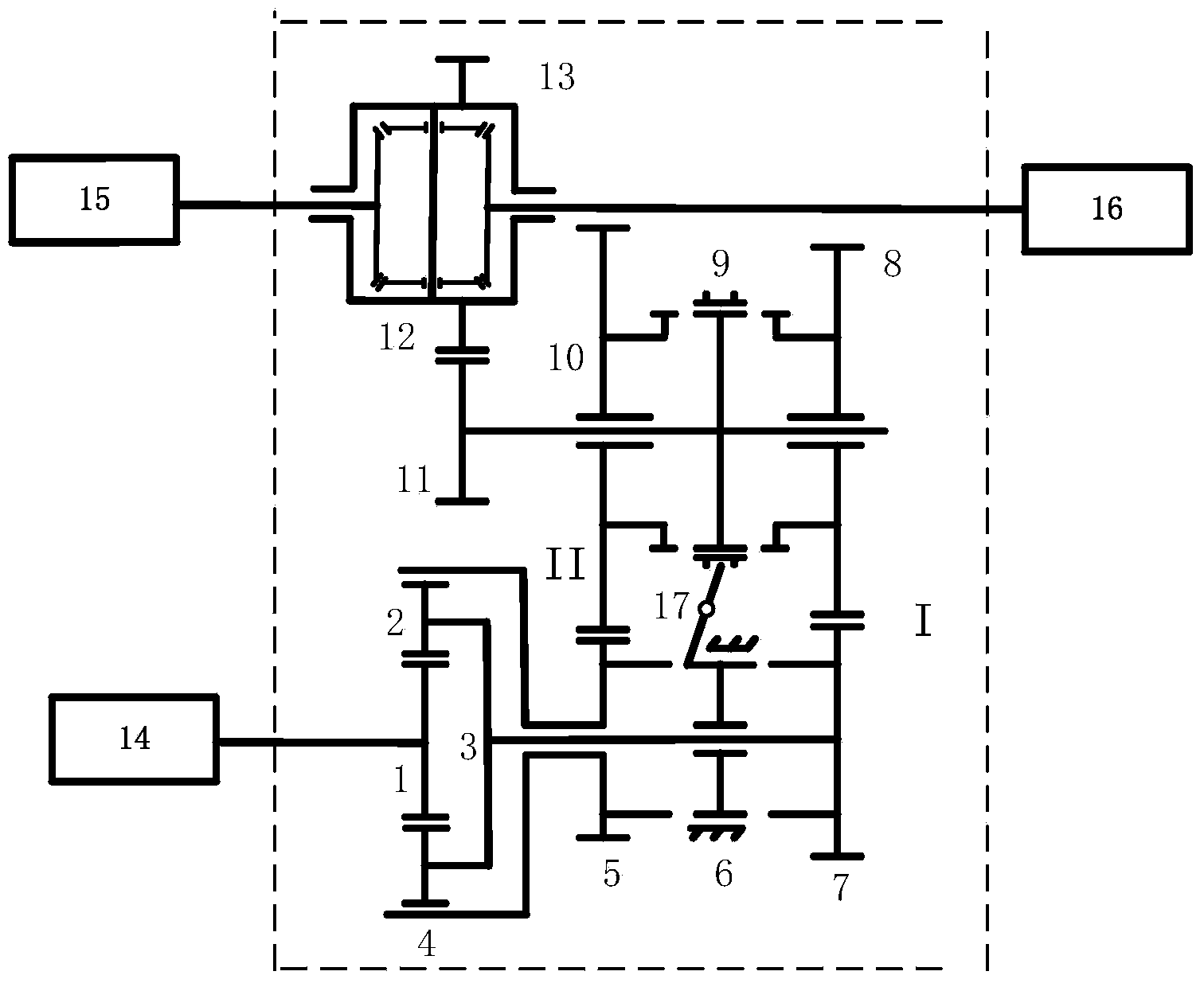

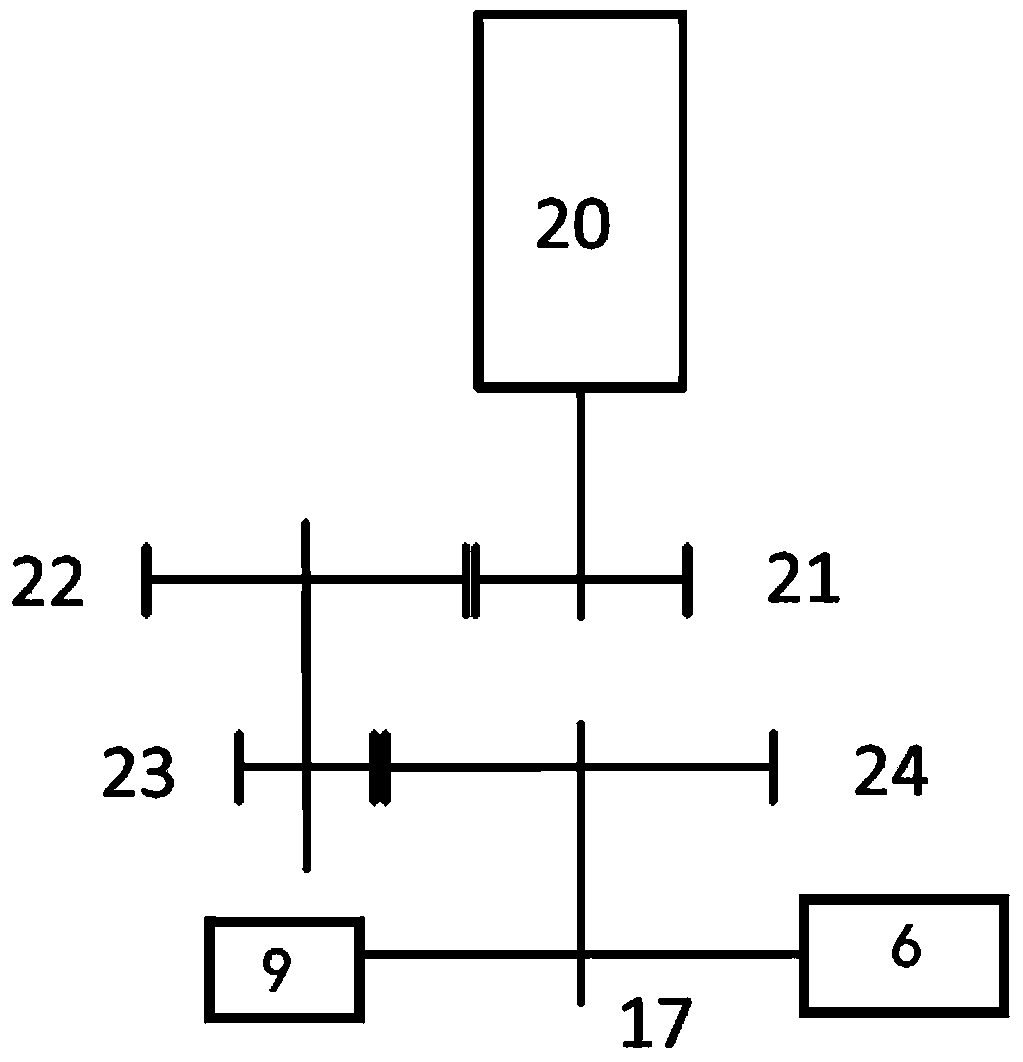

[0018] Such as figure 1 As shown, the present embodiment includes: input drive motor 14, planetary gear train, first gear driving gear 7, first gear driven gear 8, second gear driving gear 5, second gear driven gear 10, shift brake 6, synchronizer 9, Shift linkage mechanism, reducer and differential, wherein: the input end of the planetary gear train is connected with the input driving motor 14, the output end is respectively connected with the first-speed driving gear 7 and the second-speed driving gear 5, and the input ends of the reducer are respectively It is connected with the first-gear driven gear 8 and the second-gear driven gear 10, and the output end is connected with the differential. meshing, the two ends of the shift lever 17 of the shift linkage mechanism are respectively provided with a shift brake 6 and a synchronizer 9, and the shift brake 6 is controlled to lock the first gear driving gear 7 or the second gear driving gear 5, and at the same time, the linkage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com