Water inlet and outlet pipe of water heater

A technology for water inlet and outlet pipes and water heater tanks, which is applied to fluid heaters, lighting and heating equipment, etc., and can solve problems such as high manufacturing costs, complicated installation, and complicated manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

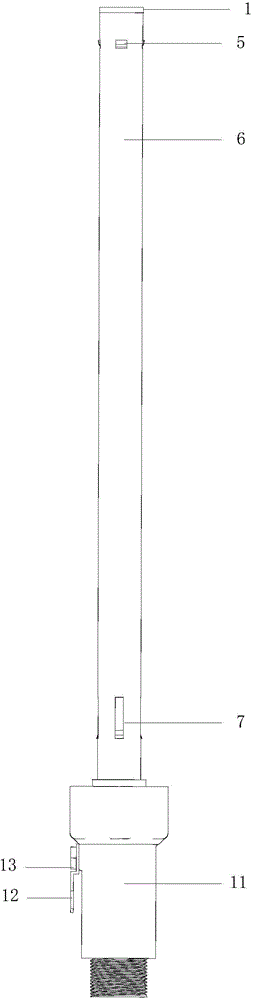

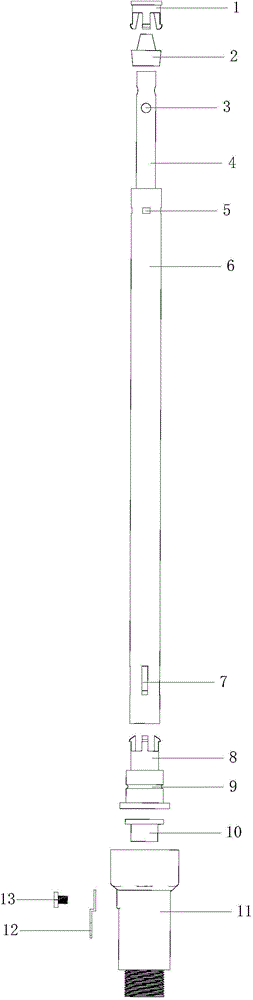

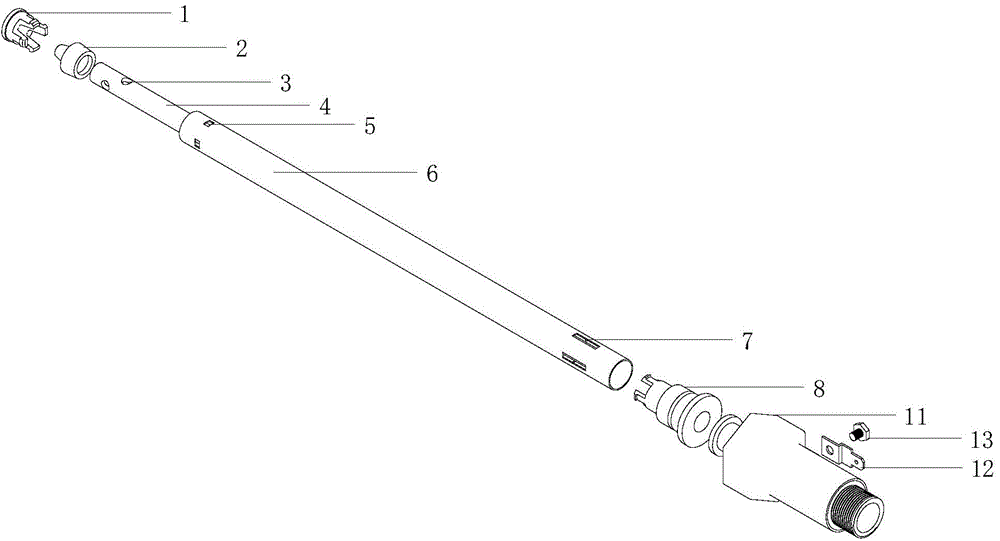

[0025] combined with Figures 1 to 4 The specific embodiment of the invention is described further:

[0026] A water heater inlet and outlet pipe includes a water pipe body and a water pipe seat. The water pipe body is located inside the water heater tank, and the water pipe seat is located outside the water heater tank. The water pipe body and the water pipe seat are connected into one body. The water pipe body includes an inner pipe 4, an outer pipe 6, a sealing plug 2, a plug support 1 and an outer pipe support 8. The plug support 1 is provided with claws. The outer tube 6 is a stainless steel tube, the length of the outer tube is compatible with the inner tube, the top of the outer tube is provided with an assembly hole 5, the claws of the plug support 1 are snapped into the assembly hole 5, and the bottom of the outer tube is provided with an outer Pipe outlet 7. The inner tube 4 is a plastic tube, the inner tube is elongated and the top end is provided with an inner t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com